pro . 28, 2024 23:53 Back to list

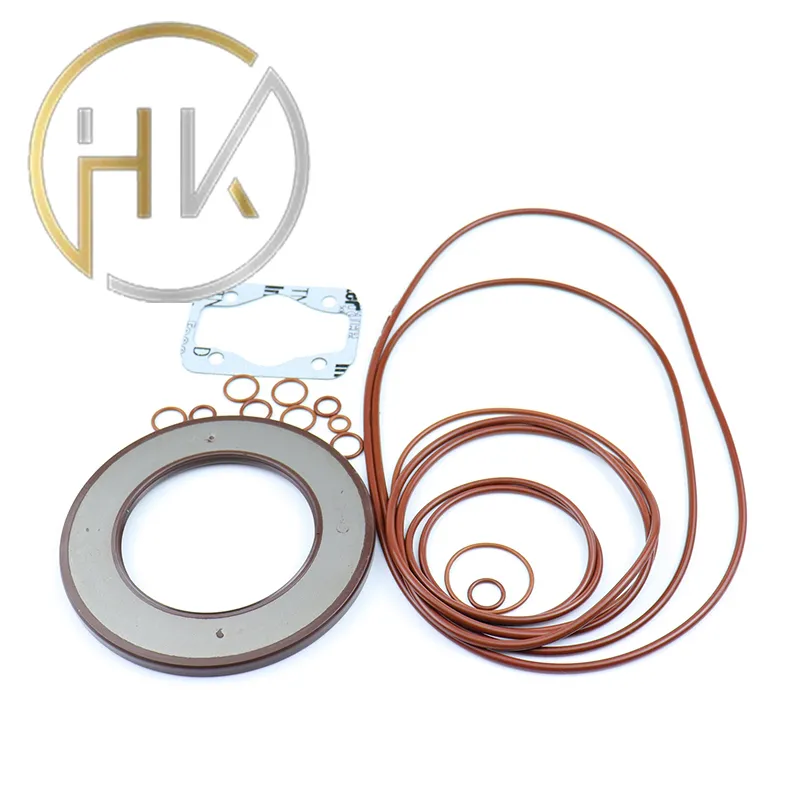

High-Performance Hydraulic Shaft Seals for Extreme Pressure Applications and Durability

High Pressure Hydraulic Shaft Seals Essential Components in Fluid Power Systems

In various industrial applications, hydraulic systems play a crucial role in generating and controlling power. At the heart of these systems are hydraulic shaft seals, which ensure effective containment of hydraulic fluids while preventing leakage and contamination. Among these seals, high-pressure hydraulic shaft seals are particularly vital due to their ability to operate under extreme pressure conditions. This article explores the function, types, applications, and considerations regarding high-pressure hydraulic shaft seals.

Function of Hydraulic Shaft Seals

Hydraulic shaft seals are designed to close the gaps between moving and stationary components in hydraulic machinery. Their primary function is to prevent the escape of hydraulic fluid and the ingress of contaminants. In high-pressure environments, maintaining integrity is paramount, as any leaks can lead to inefficiency, reduced operational performance, and potential damage to components. High-pressure seals are engineered to withstand the rigors of intense pressure and provide a reliable barrier against fluid loss.

Types of High-Pressure Hydraulic Shaft Seals

There are several different types of high-pressure hydraulic shaft seals, each suited for particular applications. Some of the most common types include

1. Lip Seals These are one of the most frequently used seals due to their effective sealing capabilities. Lip seals are designed with a flexible lip that maintains contact with the shaft, creating a seal that can withstand high pressures. They come in various materials, including nitrile rubber, fluorocarbon, and polyurethane.

2. Mechanical Seals Often employed in higher-pressure systems, mechanical seals consist of two flat surfaces that are pressed together. This type of seal is highly effective in preventing fluid leakage and is often used in rotating equipment. Mechanical seals can handle high temperatures and pressures, making them ideal for heavy-duty applications.

3. O-rings While not exclusively for high-pressure applications, O-rings can be used in conjunction with grooves and backup rings to enhance their sealing capabilities at higher pressures. Made from various elastomeric materials, O-rings are versatile and economical.

4. Square Cut Seals These seals are typically used in dynamic applications and can provide a robust sealing solution under high pressure. Their design minimizes the risk of extrusion, a common problem in high-pressure scenarios.

Applications of High-Pressure Hydraulic Shaft Seals

High-pressure hydraulic shaft seals are widely used across various sectors

. Some of the prevalent applications includehigh pressure hydraulic shaft seals

- Automotive Industry In automotive manufacturing, hydraulic systems are used in power steering and braking systems, where reliable seals are necessary to maintain system integrity and safety.

- Construction Machinery Equipment such as excavators and bulldozers relies on hydraulic systems for their operation. High-pressure seals ensure that hydraulic fluids remain contained, facilitating smooth and powerful operation.

- Aerospace In the aerospace sector, hydraulic systems are critical for control surfaces and landing gear. Seals must adhere to strict regulatory standards to ensure safety and performance.

- Marine Applications Hydraulic systems on ships and submarines require robust seals to withstand high pressures associated with underwater operations.

Considerations for Choosing High-Pressure Seals

When selecting high-pressure hydraulic shaft seals, several factors must be taken into account to guarantee optimal performance

- Material Compatibility The material of the seal must be compatible with the hydraulic fluid and the environmental conditions, including temperature and exposure to chemicals.

- Pressure Rating It is essential to ensure that the seal is rated for the specific pressure levels of the hydraulic system. Using a seal designed for lower pressures in a high-pressure application can result in premature failure.

- Operating Temperature High temperatures can degrade seal materials, leading to leaks. Selecting a seal that can withstand the operating temperature range is crucial.

- Installation and Maintenance Proper installation is vital for the performance of hydraulic seals. Consideration should also be given to maintenance schedules to replace seals before they degrade.

In conclusion, high-pressure hydraulic shaft seals are indispensable components of hydraulic systems, ensuring efficient operation and system reliability. Their design varies to accommodate different applications, and understanding their function and selection criteria is vital for engineers and technicians working with hydraulic machinery. Investing in high-quality seals not only enhances performance but also prolongs the lifespan of hydraulic systems, making them a worthwhile consideration in any fluid power application.

-

Durable 22x35x6 TCV Oil Seals: FKM & NBR for Hydraulic Pumps

NewsSep.01,2025

-

Cassette Seal 15018014.5/16 Hub Oil Seal | OEM Quality 000051785

NewsAug.31,2025

-

DKBI Hydraulic Wiper Seal 20x32x6/9 | Dustproof & Standard Oil Seal

NewsAug.30,2025

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

NewsAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

Products categories