दिसम्बर . 24, 2024 12:05 Back to list

Understanding the Functionality of Pneumatic Wiper Seals in Industrial Applications

Understanding Pneumatic Wiper Seals Functionality and Applications

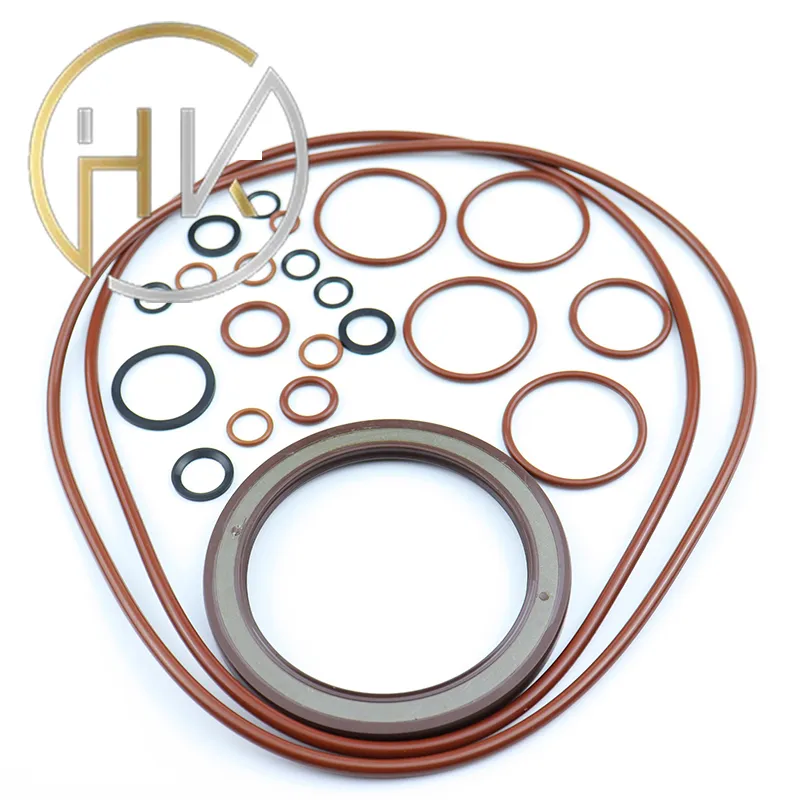

Pneumatic wiper seals are essential components in various industrial applications where the prevention of contamination and the protection of moving parts from external elements are critical. These seals play a vital role in the operation of pneumatic cylinders and systems, ensuring that they function smoothly and efficiently by keeping dirt, dust, and moisture out while also retaining lubrication.

What is a Pneumatic Wiper Seal?

At its core, a pneumatic wiper seal is designed to wipe away debris from the surface of a rod or piston when it moves in and out of a cylinder. Typically installed at the exterior of a pneumatic cylinder, these seals serve as the first line of defense against particulate contamination. They are often made from elastomers or thermoplastics that exhibit excellent wear resistance and flexibility, allowing them to maintain an effective seal even under dynamic conditions.

The design of pneumatic wiper seals can vary, but they typically include features such as lip shapes that conform to the rod's surface, ensuring that any contaminants that could enter the cylinder are effectively wiped away. This preventive measure is crucial for extending the lifespan of both the seal and the entire pneumatic system.

Importance of Pneumatic Wiper Seals

1. Contamination Prevention One of the primary functions of pneumatic wiper seals is to protect the internal components of pneumatic cylinders from dust, dirt, and other contaminants. These particles can cause significant wear and tear within the system, leading to reduced performance and potential failures.

2. Enhancing Performance By keeping the working surfaces clean, wiper seals help to maintain the efficiency of pneumatic systems. A clean operating environment ensures that the seals can perform their function without unnecessary resistance, which in turn allows for smoother movement and faster operation.

pneumatic wiper seal

3. Increasing Lifespan of Components Effective wiper seals help prolong the lifespan of pneumatic components. By preventing contaminants from entering critical areas, these seals reduce the need for maintenance and potential replacements, saving both time and resources.

4. Cost-Effectiveness Investing in high-quality pneumatic wiper seals can lead to lower operational costs in the long run. Minimizing downtime due to equipment failure and reducing maintenance frequency are significant economic advantages for any industry reliant on pneumatic systems.

Applications of Pneumatic Wiper Seals

Pneumatic wiper seals are used across a range of industries, including automotive, manufacturing, and packaging. In the automotive sector, they are commonly found in pneumatic lifts or brakes, where clean and efficient operation is paramount. In manufacturing, pneumatic tools and machinery frequently utilize these seals to ensure reliable performance in often harsh environments.

Additionally, the packaging industry employs pneumatic wiper seals in machinery that requires high levels of cleanliness, such as food processing or pharmaceutical packaging, where contamination could lead to significant safety concerns.

Conclusion

Pneumatic wiper seals are a critical yet often overlooked element in the functioning of pneumatic systems. Their ability to wipe away contaminants helps maintain system integrity, improve performance, and extend the life of machinery. Understanding the importance and functionality of these seals can lead to better maintenance practices and enhanced operations in various industrial applications. For industries that rely on pneumatic technology, ensuring that the right wiper seals are selected and properly installed can significantly influence operational efficiency and safety.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories