अक्टूबर . 12, 2024 17:11 Back to list

oil seal kit

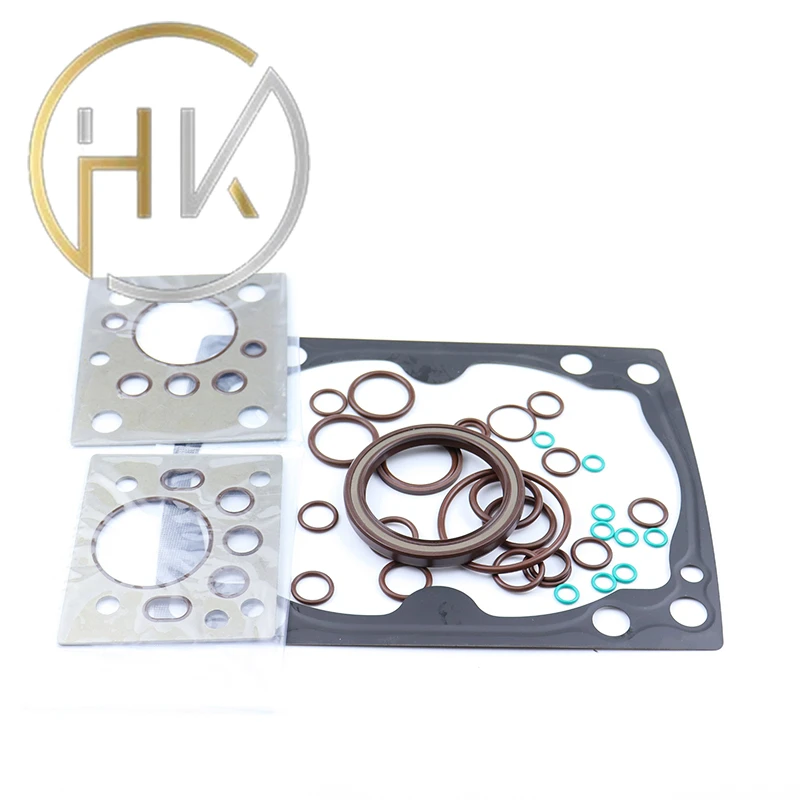

Understanding Oil Seal Kits Importance, Components, and Applications

Oil seal kits play a crucial role in various mechanical systems, providing effective sealing solutions to ensure the longevity and optimal performance of machinery. Whether in automotive, aerospace, or industrial applications, these kits are designed to prevent oil leakage, protect against contaminants, and maintain the integrity of moving parts. This article delves into the importance of oil seal kits, their components, and their wide-ranging applications.

What is an Oil Seal Kit?

An oil seal kit is a collection of oil seals, often accompanied by additional components like O-rings and gaskets, used to create a sealing solution for different machinery and equipment. The primary function of oil seals is to contain lubricants such as oil, preventing them from leaking out of the system while also keeping contaminants like dirt and moisture from entering. This dual protection is vital for the efficient operation of machines, as any loss of lubrication can lead to increased friction, overheating, and eventual failure.

Importance of Oil Seal Kits

1. Prevention of Lubricant Loss Oil seals are designed to withstand high pressure and temperature fluctuations, maintaining the necessary lubricant levels in mechanical systems. The sealing effect ensures that even under extreme operational conditions, the oil remains contained, lessening the risk of system failure due to inadequate lubrication.

2. Protection Against Contaminants Machinery operates in various environments that can introduce dirt, dust, and moisture. Oil seal kits serve as a barrier, preventing these contaminants from entering critical areas of the engine or machinery. This protection is crucial for extending the life of components and reducing maintenance costs over time.

3. Enhanced Performance By preventing leaks and contamination, oil seal kits help maintain consistent lubrication and operating temperatures. This leads to smoother operation and can significantly enhance the performance and efficiency of machinery.

4. Cost Efficiency Regular maintenance and replacement of oil seals can be less costly than dealing with the consequences of oil leaks or equipment failure. Using oil seal kits can lead to long-term savings in repair costs, as they facilitate easier maintenance schedules and minimize downtime.

Components of an Oil Seal Kit

An oil seal kit typically includes several essential components

oil seal kit

- Oil Seals These are the primary components of the kit and come in various sizes and materials, including rubber, silicone, and polyurethane. The material selection depends on the specific application and the fluid being sealed. - O-Rings These circular seals create a tight fit between two surfaces, preventing leaks and allowing for some degree of movement between components.

- Gaskets Used to cover larger surfaces, gaskets provide additional sealing and prevent fluid escape from flanged joints and other connections.

- Installation Tools Many oil seal kits come with tools designed to assist in the proper installation of seals, ensuring a successful and leak-proof application.

Applications of Oil Seal Kits

Oil seal kits are versatile and can be found in a wide range of applications

- Automotive In vehicles, oil seals are found in engines, differentials, and transmissions, where they are critical for containing oil and preventing leaks that could compromise performance.

- Industrial Machinery Machines in manufacturing facilities use oil seals to ensure proper lubrication, leading to reliable and continuous operation in various types of equipment such as pumps, compressors, and turbines.

- Aerospace Oil seal kits are essential in aircraft engines and hydraulic systems, where weight reduction and failure prevention are paramount.

- Marine In boats and ships, oil seals help protect against water ingress while maintaining lubricant containment, which is vital for the function of various onboard systems.

Conclusion

Oil seal kits are indispensable in maintaining the efficiency and longevity of machinery across different industries. Understanding their components and applications helps in selecting the right kit for specific needs, thus ensuring optimal performance and reliability. Proper maintenance and timely replacement of oil seals can prevent costly repairs and extend the lifetime of equipment, making oil seal kits a sound investment for any mechanical system. Whether in your car, industrial machinery, or aerospace applications, recognizing the importance of these kits can make all the difference in operational success.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories