दिसम्बर . 11, 2024 09:17 Back to list

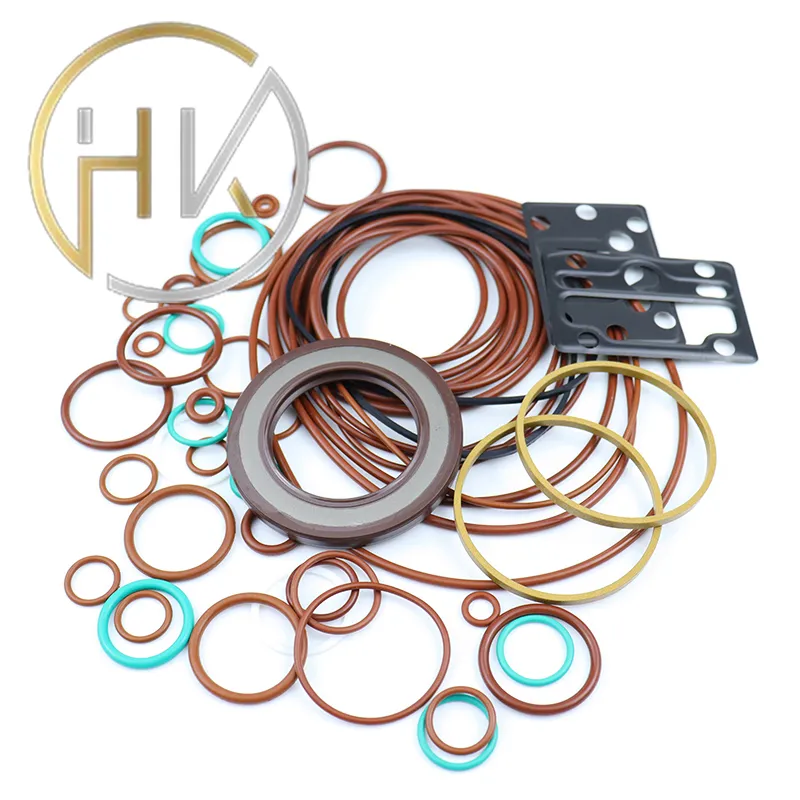

Enhancing Performance with Dual Lip Oil Seal Technology for Reliable Sealing Solutions

Understanding Double Lip Oil Seal Design, Function, and Applications

In the world of mechanical engineering, seals play a crucial role in ensuring the efficiency and reliability of various machines and devices. Among the numerous types of seals, the double lip oil seal stands out due to its unique design and multifunctional capabilities. This article delves into the specifics of double lip oil seals, their construction, functionality, and a variety of applications across different industries.

Design and Construction

A double lip oil seal is characterized by two sealing lips that make direct contact with the shaft or housing. This design effectively provides a secondary barrier against the infiltration of contaminants and the escape of lubricants. The seal typically comprises a metal casing that provides structural integrity, rubber or elastomeric materials for the sealing elements, and a spring that exerts pressure on the lips to maintain a tight fit against the shaft.

The material selection for the sealing lips is critical. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and polyacrylate, each offering different temperature resistance, chemical compatibility, and durability. The design parameters, such as lip configuration, hardness, and spring design, can be tailored to meet specific functional requirements, making double lip seals customizable for various applications.

Functionality

The primary function of the double lip oil seal is to contain lubricant within a system while preventing contamination from external elements. The two lips work in tandem; the primary lip is responsible for preventing oil leakage, while the secondary lip serves as an additional defense against dust and dirt. This dual protection is particularly advantageous in environments exposed to harsh conditions, such as heavy machinery, automotive systems, and industrial equipment.

double lip oil seal

Another important aspect of double lip seals is their ability to handle radial and axial movements. The flexibility of the sealing lips allows them to adapt to slight misalignments and shaft vibrations, thereby maintaining a reliable seal throughout the operational life of the equipment. This feature is particularly beneficial in rotating machinery where shaft movement is inevitable.

Applications

Double lip oil seals find a wide range of applications across various industries. In the automotive sector, they are commonly used in engines, gearboxes, and differentials, providing essential containment for oils and lubricants while protecting against dirt and moisture. Their reliability in sealing ensures the longevity of automotive components, contributing to overall vehicle performance.

In the industrial realm, double lip seals are utilized in hydraulic systems, pumps, and compressors. They prevent hydraulic fluid leakage and contamination, thereby enhancing the efficiency of hydraulic machines. Additionally, these seals are also employed in the manufacturing of household appliances, such as washing machines and dishwashers, where moisture resistance is key to performance.

The mining and aerospace industries also benefit from the robustness of double lip oil seals. In mining equipment exposed to abrasive dust and rough terrain, these seals prevent contaminants from entering critical components, ensuring operational efficiency. In aerospace applications, where reliability is paramount, double lip seals help maintain the integrity of lubricants in rotating machinery while resisting extreme temperatures and pressures.

Conclusion

The double lip oil seal is a vital component in numerous mechanical systems, providing unparalleled seals against fluids and contaminants. With its innovative design, adaptability, and application versatility, the double lip seal stands as a testament to the important role of sealing technology in enhancing the performance and reliability of a wide array of machines and devices. As industries continue to evolve and demand higher efficiency, the importance of reliable sealing solutions like the double lip oil seal will only grow, paving the way for further advancements in mechanical engineering and design.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories