दिसम्बर . 14, 2024 05:41 Back to list

5 inch hydraulic cylinder seal kit

Understanding the Importance of a 5% 20 Inch Hydraulic Cylinder Seal Kit

Hydraulic systems play a vital role in various industrial applications, from construction machinery to manufacturing equipment. Central to the functionality of these systems is the hydraulic cylinder, which converts hydraulic energy into mechanical energy. The performance and longevity of a hydraulic cylinder heavily depend on the integrity of its components, particularly the seal kits. This article will delve into the significance of a 5% 20 inch hydraulic cylinder seal kit, its components, common applications, and maintenance tips to ensure optimal performance.

What is a Hydraulic Cylinder Seal Kit?

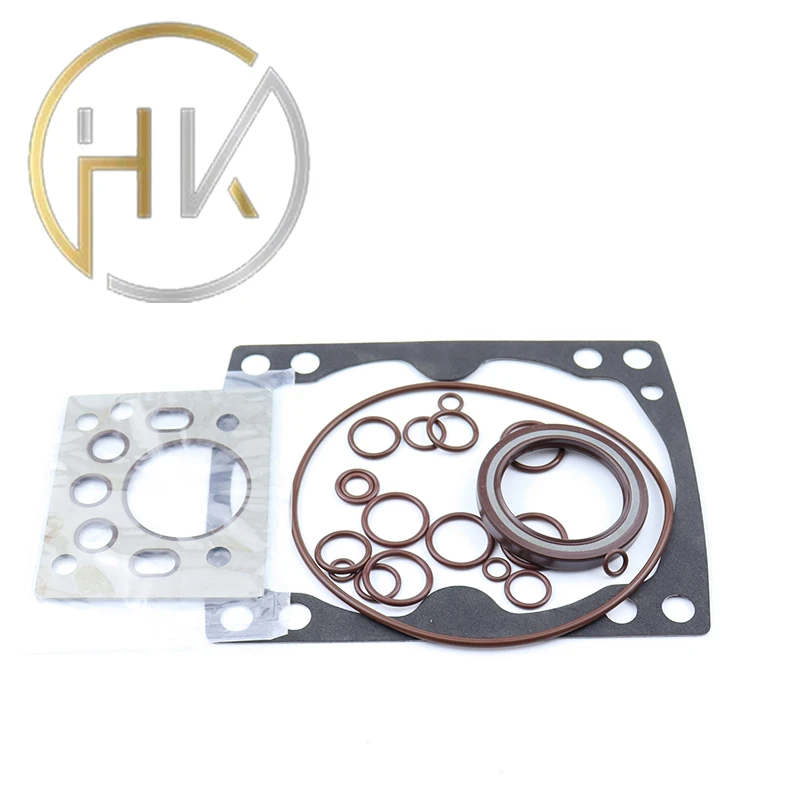

A hydraulic cylinder seal kit is a collection of components designed to prevent the escape of hydraulic fluid, thereby ensuring the efficient operation of hydraulic cylinders. A typical seal kit may include various seals, O-rings, backup rings, and wipers, each component serving a specific purpose in preventing leaks and maintaining hydraulic pressure.

The term 5% 20 inch likely refers to the specifications of the seal kit, where 20 inch indicates the diameter of the hydraulic cylinder and 5% could relate to the tolerance or fit of the seals in relation to that diameter. In essence, these seals play a critical role in creating a robust seal that withstands high pressures while allowing smooth movement of the cylinder's components.

Importance of Quality Seal Kits

The integrity of the seal kit is paramount for the performance and efficiency of hydraulic systems. Poor-quality seals can lead to fluid leaks, which not only decrease the efficiency of the machine but also cause potential environmental hazards. Fluid leakage can also lead to severe damage to the hydraulic system, resulting in costly repairs and downtime.

A high-quality 5% 20 inch hydraulic cylinder seal kit can enhance the durability of the hydraulic cylinder, improve operational efficiency, and reduce maintenance costs. When selecting a seal kit, it is essential to consider factors such as the material of the seals (e.g., rubber, polyurethane, or PTFE), the operating environment, and the specific hydraulic fluid in use.

Common Applications

Hydraulic cylinders are widely used across various industries, making seal kits essential components of machinery in diverse applications. Some common uses include

1. Construction Hydraulic cylinders are standard in excavators, loaders, and cranes. These machines require robust seal kits to withstand the rigors of heavy lifting and terrain challenges. 2. Manufacturing Hydraulic presses and injection molding machines rely on effective seals for precise operations, ensuring that products are made to exact specifications.

5 inch hydraulic cylinder seal kit

4. Automotive Hydraulic systems in vehicles—including power steering and braking systems—depend on high-quality seals to function safely and effectively.

Maintenance Tips

To extend the lifespan of a hydraulic cylinder and its seal kit, regular maintenance is essential. Here are some best practices

1. Regular Inspections Periodically inspect hydraulic cylinders for any signs of fluid leakage, wear, or damage to seals. Early detection can prevent further damage and more significant repair costs.

2. Proper Installation Ensure that seals are installed correctly, following manufacturer guidelines. Incorrect installation can lead to premature wear or failure.

3. Cleanliness Maintain cleanliness when working with hydraulic systems. Contaminants can quickly damage seals, leading to leaks and compromised performance.

4. Monitor Fluid Quality Regularly check the hydraulic fluid for contamination. Poor fluid quality can lead to seal degradation and overall system failure.

5. Temperature Control Be aware of the operating temperatures of hydraulic cylinders. Excessive heat can impact the performance of seals, causing them to harden or deform.

In conclusion, a 5% 20 inch hydraulic cylinder seal kit is a vital component in ensuring the efficiency, safety, and longevity of hydraulic systems across various industries. By investing in quality seal kits and adhering to maintenance best practices, operators can optimize the performance of their hydraulic cylinders, ultimately leading to increased productivity and reduced operational costs. Whether in construction, manufacturing, agriculture, or automotive applications, the importance of a reliable seal kit cannot be overstated.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories