דצמ . 11, 2024 23:32 Back to list

seal kit cylinder

Understanding Seal Kit Cylinders A Comprehensive Guide

Seal kit cylinders are essential components in various hydraulic and pneumatic systems, providing necessary physical barriers to prevent the leakage of fluids. Their importance cannot be overstated, as they ensure the efficiency, reliability, and longevity of machinery in diverse industries, from manufacturing to automotive assembly, and even aerospace applications. In this article, we will delve into the concept of seal kit cylinders, explore their types, applications, and maintenance tips to ensure optimal performance.

What is a Seal Kit Cylinder?

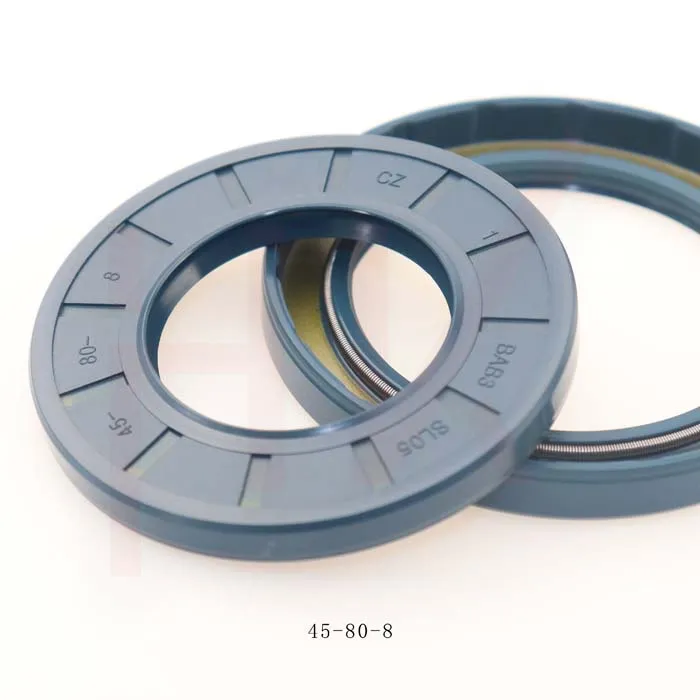

A seal kit cylinder typically consists of a cylinder barrel, piston, and sealing components that work together to form a functional unit in hydraulic or pneumatic systems. These cylinders are designed to create pressure differentials that facilitate movement, making them vital for powering machinery and equipment. The seal kits themselves contain various seals, O-rings, and gaskets that are responsible for preventing fluid leakage which could compromise the system’s operation.

Types of Seal Kits

Seal kits can be categorized based on various criteria, including the type of fluid they manage, the environment in which they operate, or their design. Some of the most common types include

1. Hydraulic Seal Kits These are designed for applications involving hydraulic fluids, such as oil or water-based solutions. Hydraulic seal kits must be robust, capable of withstanding high pressures and extreme temperatures.

2. Pneumatic Seal Kits These kits are tailored for air or gas applications, focusing on lower pressure differentials compared to hydraulic systems. They are typically made of elastomeric materials that can sustain the unique demands of pneumatic operations.

3. Custom Seal Kits Custom seal kits are designed based on specific system requirements, often for unique machinery or conditions that standard kits cannot meet. This customization may involve selecting specific materials, dimensions, or seal types.

Applications of Seal Kit Cylinders

Seal kit cylinders find application in a multitude of industries, including

- Manufacturing Used in machines that require precise movements and pressure control, such as injection molding machines and hydraulic presses. - Automotive Critical for power steering systems, brake systems, and various actuator mechanisms within vehicles to ensure safety and efficiency.

seal kit cylinder

- Aerospace Employed in airplane components and systems, where precision and reliability are paramount.

- Construction Utilized in heavy equipment like excavators, bulldozers, and material handlers, where hydraulics power numerous functions.

Maintenance of Seal Kit Cylinders

To maximize the lifespan and efficiency of seal kit cylinders, regular maintenance is crucial. Here are some tips

1. Routine Inspection Regularly check seals for wear, tear, or signs of leakage. Catching potential issues early can prevent costly repairs or equipment failures.

2. Fluid Quality Ensure the hydraulic or pneumatic fluids used are of high quality and appropriate for the seals. Contaminated or incorrect fluids can degrade seals faster.

3. Proper Installation When installing or replacing seal kits, adherence to manufacturer guidelines is vital. Incorrect installation can lead to premature failure of the sealing mechanism.

4. Environmental Factors Be mindful of the operating environment. Temperature fluctuations, exposure to chemicals, and excessive moisture can adversely affect seal performance.

5. Scheduled Maintenance Develop a maintenance schedule that includes periodic checking and replacing of seal kits as needed. This proactive approach can save time and resources in the long run.

Conclusion

Seal kit cylinders play an indispensable role in the functionality of hydraulic and pneumatic systems across various industries. By understanding their components, types, and applications—and by committing to proper maintenance—operators can ensure the efficiency and longevity of their machinery. As technology advances, staying informed about the latest developments in seal technology and material science will further enhance performance and reliability in industrial systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories