פבר . 12, 2025 17:59 Back to list

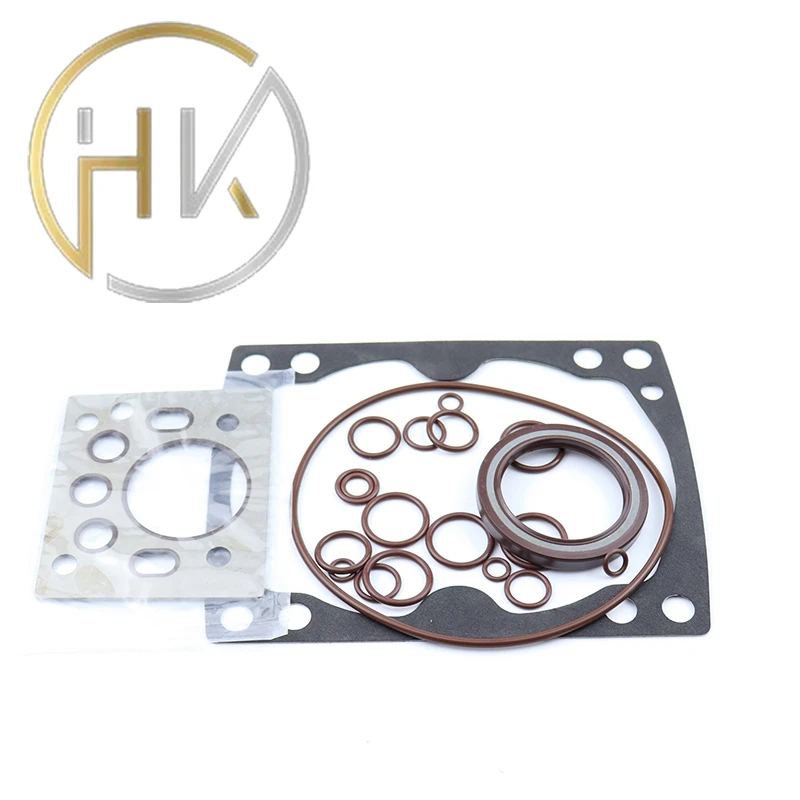

mechanical seal kit

Trustworthiness in mechanical seal kits stems largely from proven performance and adherence to industry standards. Certifications such as ISO 9001 for quality management systems or API 682 for sealing systems in the oil and gas industry are indicative of a manufacturer's commitment to quality. By choosing certified products, companies not only protect their equipment but also safeguard against potential legal and environmental repercussions. Moreover, conducting periodic reviews and maintenance of mechanical seals with trusted service providers ensures their continued efficiency and reliability. Considering the investment required for high-performance mechanical seal kits, it is paramount for enterprises to enforce a robust procurement process. Evaluating vendors based on their reputation, product warranties, and service support can significantly impact operational efficiency and equipment lifespan. It’s advisable to collaborate with vendors who offer comprehensive installation and maintenance support, as well as training for technical personnel, ensuring that the implementation of the mechanical seals is both effective and sustainable. In the face of evolving industrial demands, mechanical seal technology continues to advance. Innovations such as split seals, which simplify maintenance and reduce system downtime, or the use of engineered polymers for improved chemical resistance, exemplify the ongoing improvements in sealing solutions. Staying abreast of technological advancements enables businesses to adapt and leverage new solutions that enhance operational performance. In conclusion, mechanical seal kits are a vital component in safeguarding the functionality and efficiency of industrial equipment. Through the lenses of Experience, Expertise, Authoritativeness, and Trustworthiness, a deeper understanding of these kits can be achieved. The strategic selection and maintenance of mechanical seals can result in significant operational and financial benefits, underscoring their importance in various industrial sectors. Facilities looking to optimize their processes must consider not only the immediate benefits of superior sealing solutions but also their long-term impact on productivity and sustainability.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories