דצמ . 05, 2024 11:39 Back to list

Hydraulic Cylinder Seal Kits for Lifts and Heavy Machinery Maintenance and Repair

Understanding Hydraulic Lift Cylinder Seal Kits

Hydraulic systems are integral to various industrial applications, from construction to manufacturing. Central to these systems are hydraulic lift cylinders, which rely on hydraulic fluid to create motion and force. However, to ensure the efficiency and longevity of these cylinders, seal kits are crucial components that warrant a detailed discussion.

What is a Hydraulic Lift Cylinder Seal Kit?

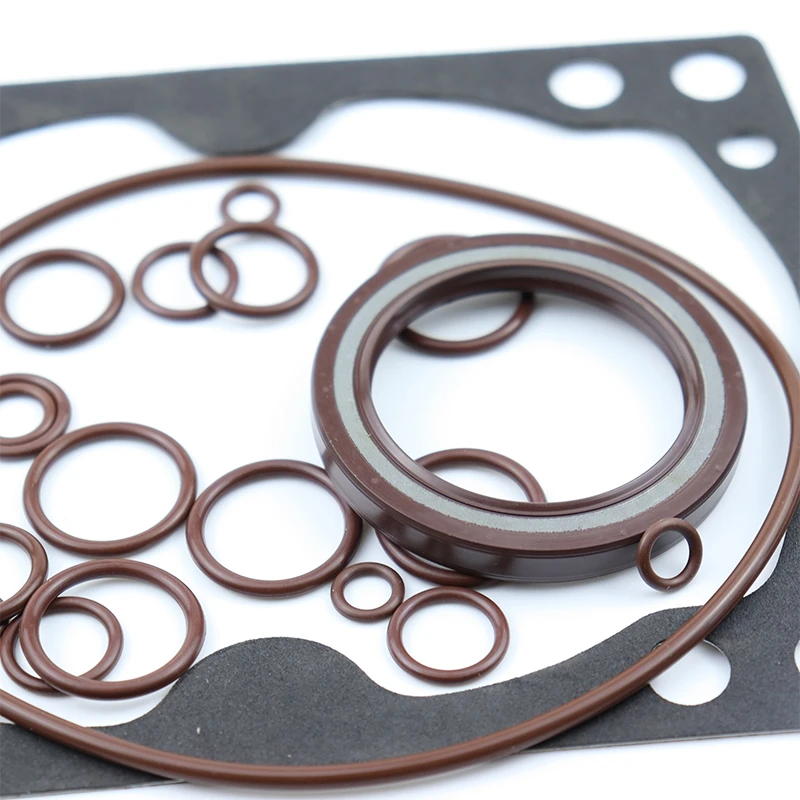

A hydraulic lift cylinder seal kit is a collection of seals and other components designed to prevent fluid leakage while maintaining the performance of hydraulic cylinders. The seals within the kit are vital for keeping the hydraulic fluid contained, which allows the cylinder to operate effectively under pressure. A typical seal kit may include O-rings, pistons, backup rings, and other essential seals, all engineered to withstand high pressure and various temperatures.

Importance of Seal Kits

The importance of using high-quality hydraulic lift cylinder seal kits cannot be overstated. Over time, seals can wear out due to continuous exposure to hydraulic fluids, heat, and the mechanical stress of operation. Worn or damaged seals can lead to leaks, decreased efficiency, and catastrophic failures in hydraulic systems. By regularly replacing seals with a comprehensive seal kit, you can prevent costly downtime, improve performance, and extend the lifespan of the hydraulic lift cylinders.

Types of Seals in Hydraulic Lift Cylinder Kits

Various types of seals are employed in hydraulic lift cylinder seal kits, each serving a unique purpose

1. O-Rings These are circular seals that fit into grooves and prevent fluid leakage. They are prevalent due to their simple design and effectiveness.

2. Piston Seals Piston seals are designed to fit between the piston and the cylinder wall, ensuring that the hydraulic fluid does not escape when pressurized.

4. Backup Rings These components support O-rings and other seals, preventing them from extruding or deforming under high pressure.

hydraulic lift cylinder seal kits

5. Wiper Seals Wiper seals serve to keep contaminants out of the cylinder, ensuring that the hydraulic fluid remains uncontaminated and maintaining the integrity of the seals.

Choosing the Right Seal Kit

When selecting a hydraulic lift cylinder seal kit, it’s essential to consider several factors

- Compatibility Ensure that the seal kit is compatible with the specific model of hydraulic cylinder you are using. Manufacturer specifications should always be checked.

- Material Seal materials should withstand the operating conditions, including temperature fluctuations and exposure to different types of hydraulic fluids.

- Quality Opt for high-quality seal kits to ensure durability and resistance against wear and tear. Investing in reputable brands is often more economical in the long run.

- Application Consider the specific application and working conditions of your hydraulic system. Different environments may require specialized seal materials or designs to function optimally.

Maintenance and Care

To maximize the lifespan of hydraulic lift cylinders and their seal kits, routine maintenance is essential. This includes regularly checking for leaks, monitoring fluid levels, and replacing seals as needed. Proper installation during seal kit replacement is crucial; improper installation can lead to immediate failure and additional damage to the system.

Conclusion

Hydraulic lift cylinder seal kits play a vital role in maintaining the efficiency and reliability of hydraulic systems. Understanding the components and selecting the right kit is critical for optimal performance. By prioritizing quality and conducting regular maintenance, operators can ensure their hydraulic systems run smoothly and efficiently, reducing costs and enhancing productivity. With the right knowledge and preparation, the longevity of hydraulic lift cylinders can be significantly improved, ensuring they continue to perform at their best for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories