פבר . 15, 2025 13:31 Back to list

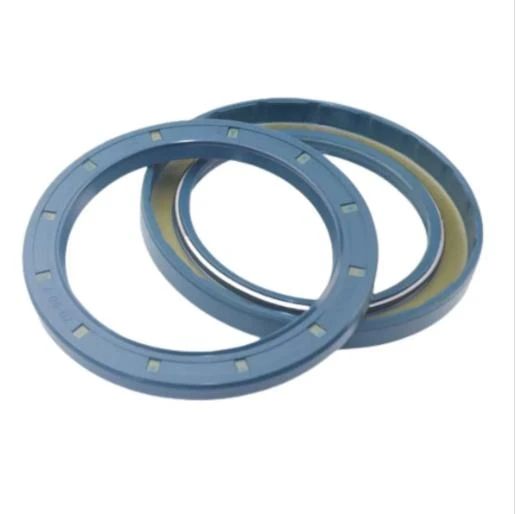

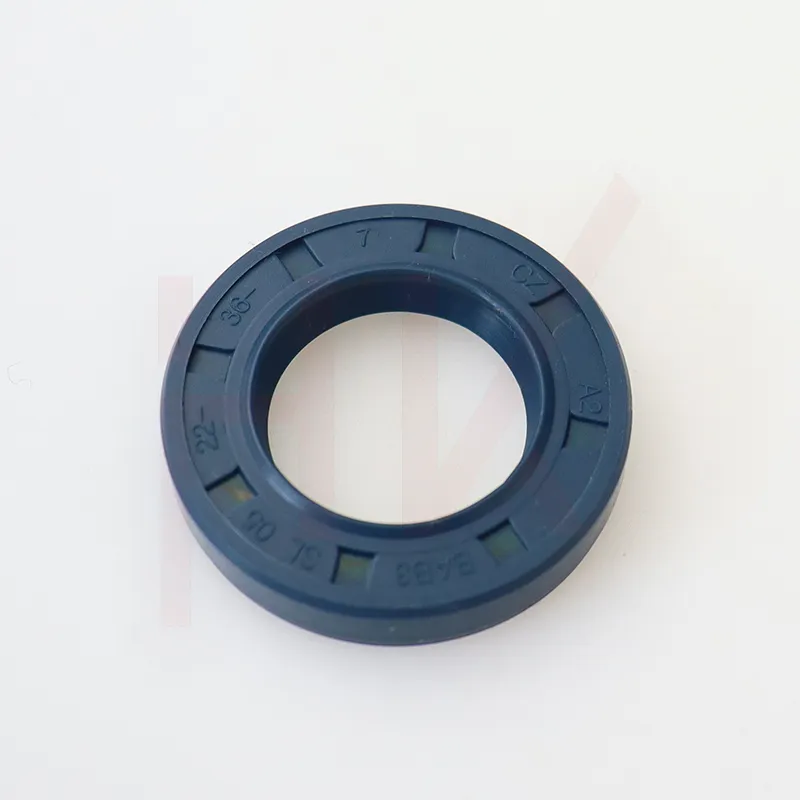

dkb seal

Moreover, car manufacturers constantly look for ways to improve fuel efficiency and performance standards, and the quality of hub dust seals directly impacts these objectives. A vehicle with well-maintained seals experiences less drag and lower fuel consumption, playing into broader goals of sustainability and economy. Thus, the choice of seals is aligned with corporate responsibility towards environmental conservation. In terms of expert advice, monitoring the condition of hub dust seals should be a routine part of any maintenance service. Early detection of seal wear can prevent more extensive damage. Look for cracks, tears, or any stiffness in the elastomer, which might indicate aging or exposure to extreme conditions. Should any of these signs be present, timely replacement of the seals should be prioritized. There's an authoritative consensus on the need for innovation in dust seal materials to address future industry needs. Researchers and manufacturers are continually working to develop new compounds with enhanced resistance to temperature extremes and chemical exposures, while also seeking to improve compatibility with various types of lubricants. Building trust with clients and consumers involves clear communication regarding maintenance schedules, the importance of quality components, and transparent information about the mechanical effects of failing to replace crucial elements like hub dust seals. Professional workshops often provide educational sessions for consumers to understand better why such components matter to their vehicle's overall health and performance. In summary, the hub dust seal, while often small and overlooked, is a vital component in machinery and vehicle maintenance. With an emphasis on experience, expertise, reliability, and trustworthiness, the selection and maintenance of hub dust seals are crucial for any operation aiming to maximize longevity and efficiency. Whether it's through careful selection of materials, expert installation, or advancements in design, keeping hub assemblies secure from contaminants not only bolsters vehicle performance but also aligns with broader industry trends towards sustainability and operational reliability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories