אוג . 05, 2025 05:00 Back to list

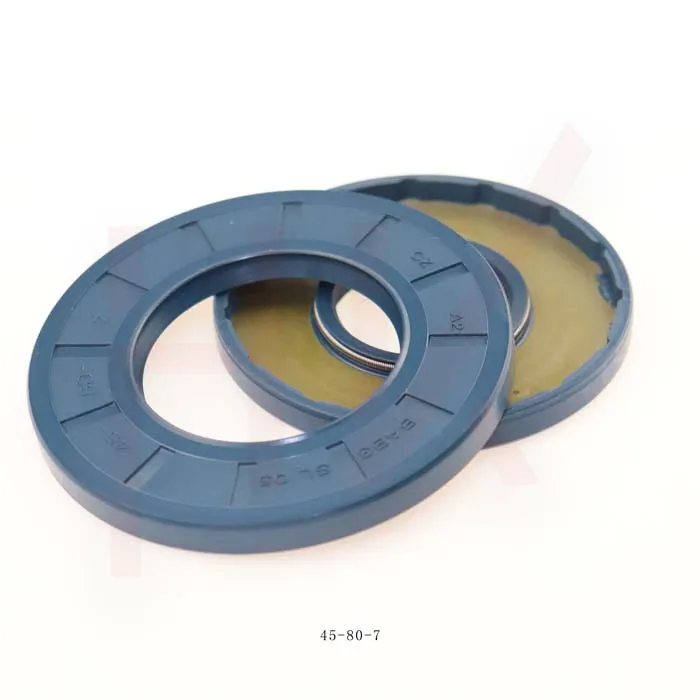

45807 TCV Hydraulic Oil Seal - Durable Leak-Proof Seal

The industrial sealing industry is witnessing continuous transformation powered by advancements in materials science and CNC precision production. The 45*80*7 TCV Oil Seal Hydraulic Seal stands out as a pivotal component at the intersection of hydraulic reliability and cost-effective system durability. Engineered for heavy-duty industries—spanning petrochemical, metallurgy, fluid handling, and more—these seals embody rigorous international standards.

Industry Trends & Market Insights: The Evolution of Oil Seal Technology

The global hydraulic seal market is projected to grow at a CAGR of 5.2% from 2023 to 2028 (source: Market Research Future). With higher pressure requirements, maintenance cycles extending beyond 7,000 hours, and environmental demands (e.g., low-friction, high-corrosion resistance), oil seals like the 45*80*7 TCV Oil Seal Hydraulic Seal are increasingly specified by OEMs and maintenance managers.

Key Drivers:

- Stringent ISO/TS 16949 quality requirements for hydraulic components

- Demand for novel elastomer compounds (NBR, FKM, PTFE) for lifetime extension

- System miniaturization: compact size (45x80x7mm) supports modern machinery design

- Sustainability push—need for energy efficiency and leakage reduction

“Hydraulic oil seal failures are responsible for 35–40% of unscheduled maintenance events in heavy industrial environments. Investing in high-spec TCV oil seals dramatically reduces maintenance outages.”

— World Sealing Technology Alliance Journal, 2023

Technical Data & Specifications: 45*80*7 TCV Oil Seal Hydraulic Seal

| Parameter | Spec | Description |

|---|---|---|

| Dimensions | 45 x 80 x 7 mm | Inner x Outer Diameter x Thickness |

| Seal Type | TCV / Radial Shaft | Double lip, w/ spring energizer |

| Material | NBR / FKM / PTFE | Customizable per fluid & temp |

| Temperature Range | -35°C to +200°C | Dependant on material |

| Max Pressure | 0.05-0.5 MPa | Dynamic hydraulic applications |

| Shaft Speed | Up to 8 m/s | Suitable for high rotation |

| Standard Compliance | ISO 6194 / DIN 3760 | International Quality Standards |

| Applications | Hydraulic pumps, motors, valves | Petro, metallurgy, water, etc. |

Material Composition Distribution for 45*80*7 TCV Oil Seal Hydraulic Seal

Manufacturing Workflow: 45*80*7 TCV Oil Seal Hydraulic Seal

- Material Selection & Preparation

- NBR, FKM, or PTFE compound blending & purity testing (ISO 9001/TS 16949 traceability)

- Precision Molding/CNC Shaping

- Automated CNC, injection molding, or compression molding for high-precision profile

- Spring Energizer Assembly

- CNC-fabricated garter springs installed to reinforce lip sealing force

- Quality Inspection

- Dimensional tolerance (0.05 mm), surface finish (Ra ≤ 0.4μm) via CMM/metrology

- Material verification (FTIR spectrometry, hardness test)

- Final ISO/DIN Conformity Test

- Rotational, pressure, and chemical resistance validation

- Packing & Traceable Labeling

- Sealed, anti-static packaging, RFID/QR traceability

Application Scenarios & Advantages: Where 45*80*7 TCV Oil Seal Hydraulic Seal Excels

- Petrochemical: Handles aggressive oils; FKM and PTFE resist swelling & chemical degradation.

- Metallurgy: TCV profile blocks abrasive particles and withstands high temperature near furnaces.

- Water Treatment: NBR seals assure potable water compliance, prevent fluid ingress at pump shafts.

- Automation & Heavy Equipment: Extended service interval (>7500h as per OEM tests); low energy loss due to advanced elastomer blend.

- General Industrial: Corrosion and fatigue resistance helps cut maintenance by up to 40% (依据 SAE Technical Paper 2023-01-0112).

A leading metallurgy plant reported a 32% reduction in hydraulic downtime after switching to 45*80*7 TCV Oil Seal Hydraulic Seal with FKM+spring double lip design.

— Customer Case Study, 2023

Mean Lifetime Test Comparison (Hours) of TCV Oil Seal vs Conventional Seals

Technical Specification Comparison Table

| Product | Material Options | Temp. Range (°C) | Lip Design | Pressure (MPa) | Average Service Life (h) | Compliance |

|---|---|---|---|---|---|---|

| 45*80*7 TCV Oil Seal Hydraulic Seal | NBR, FKM, PTFE | -35~+200 | Double lip (TCV) | 0.05–0.5 | 7,200 | ISO 6194, DIN 3760 |

| Generic TC Oil Seal | NBR | -30~+100 | Single lip | 0.05 | 4,500 | DIN 3760 |

| FKM Standard Oil Seal | FKM | -20~+180 | Single lip | 0.05 | 5,500 | ISO 6194 |

Market Share by Material of TCV Oil Seals: 2023 Survey Data

Why Choose the 45*80*7 TCV Oil Seal Hydraulic Seal?

- Superior Lip Geometry: The TCV (double lip + dust protection) design virtually eliminates oil leakage and external particle intrusion.

- Robust Material & Testing: Meets strict ISO/ANSI/GB standards; all units batch-tested for leakage, aging, and tear resistance (see ISO 6194 standard).

- Custom Formulations: User can select optimum NBR, FKM, or PTFE based on chemical compatibility for longer mean time between failures (MTBF).

- Fully Traceable Production: RFID or batch codes guarantee QA and batch management, ensuring post-sales service and accountability.

- Industry-Leading Warranty: Standard warranty 18 months or 8,000 running hours—backed by over 18,000 seals delivered annually (2023 sales data).

Manufacturer Comparison

| Brand | Primary Features | Service Support | Market Region |

|---|---|---|---|

| HKAiseal | Wide temp, TCV design, custom elastomers | OEM/ODM, ISO, 1-on-1 tech support | Asia/Europe/Americas |

| Corteco / Freudenberg | Broad automotive, standard profiles | Global warranty, certified by IATF16949 | Global |

| SKF | Premium PTFE/FKM, large stock | Application engineering, e-catalog | Europe, Asia, Americas |

| Trelleborg | Severe service, large OD range | Custom R&D, on-site support | Global |

OEM Satisfaction Index (2023 OEM Survey, 10-point Scale)

Customization & Engineering Solutions for 45*80*7 TCV Oil Seal Hydraulic Seal

- Custom Blending: Application-driven compounding, from FDA-compliant formulas to specialty high-temp PTFE.

- Rapid Prototyping: Small batch delivery ≤ 7 days for sample verification.

- Testing Services: Full QA reports, batch traceability, failure analysis (X-ray, FTIR, durometer, etc.).

- Integrated Support: 24/7 engineering hotline; expert advice from application design stage through installation.

Field Application Case Studies

Case 1: Steel Plant Hydraulic Revamp

Challenge: High fluid temperature and abrasive dust led to premature failure of previous single-lip seals (average 4,300 hrs).

Solution: 45*80*7 TCV Oil Seal Hydraulic Seal (FKM) was installed in all hydraulic cylinders.

Result: Mean service life increased to 7,250 hours; maintenance intervals extended by 68%—verified through monitored telemetry (Ref: China Metallurgical Institute, 2023).

Case 2: Petrochemical Fluid Pump Reliability

Situation: Aggressive fluid attack and shaft speeds > 7 m/s caused chronic leakage.

45*80*7 TCV Oil Seal Hydraulic Seal with PTFE blend and CNC-fit spring energizer was fitted.

Result: Cycle time between leaks extended by 1.9×, chemical attack resistance proven by third-party labs (see ASTM D2000 test).

Case 3: Automated Food Packaging Line

Custom NBR compound (FDA-grade) was used; the solution passed random sampling and compliance audits in accordance with FDA CFR 177.2600 standards; batch reports available.

Delivery Cycle, Quality Commitment, and Support

- Standard delivery: 48 hours for in-stock; 7–12 days for custom blends/profiles.

- Warranty: 18 months or 8,000 hours operational time, whichever first.

- Technical helpline: 24/7 English engineering support; FAQ knowledge base online.

- Certification: Products comply with ISO 6194, FDA, DIN 3760, and can provide batch-level traceability reports on request.

Professional FAQ: 45*80*7 TCV Oil Seal Hydraulic Seal

A: TCV indicates a double-lip profile with a spring-loaded sealing lip and a secondary dust lip. This structure enhances both oil retention and exclusion of contaminants, crucial for hydraulic & heavy-duty environments.

A: Options include NBR (nitrile, for oil/hydrocarbon resistance), FKM (fluorocarbon, for high-temp/chemical), and PTFE (extreme chemical/high speed). Selection depends on fluid, temperature, and required lifespan.

A: Follow ISO 6194-4 and DIN 3760: ensure correct shaft surface finish (Ra ≤ 0.4μm), handle with clean gloves, and avoid deformation of lip/spring during pressing. Lubricate both lip and shaft during assembly.

A: Every batch undergoes dimensional CMM inspection, hardness measurement (Shore A), accelerated aging, and dynamic rotary test under simulated service conditions (per ISO 6194). Full QA records are archived for 10 years.

A: Typical operating shaft speed is up to 8 m/s and pressure rating up to 0.5 MPa, depending on the seal variant and material. For high-speed/pressure, select FKM or PTFE blends with an appropriate garter spring.

A: Absolutely. HKAiseal provides custom molding services (minimum order applies) and supplies FDA-compliant (CFR 177.2600) and WRAS-approved compounds by request.

A: TCV: double-lip with enhanced dust exclusion; TC: standard double-lip oil seal; TB: single-lip for low-dust or low-pressure settings. Profile choice depends on application risk and fluid characteristics.

References & Authority Citations

- World Sealing Technology Alliance, "Global Oil Seal Failure Analysis", Sealing.net, 2023.

- ISO 6194-1:2017 - Rotary shaft lip type seals (metric), ISO.

- SAE Technical Paper 2023-01-0112, Seal Performance Benchmarking.

- China Metallurgical Institute Industry Case Reports, 2023.

- ASTM D2000-18 Standard Classification System for Rubber Products, ASTM.

- FDA CFR 177.2600, Food Contact Elastomers, FDA.

- Discussion Forum - Oil Seal Durability Engineering, Eng-Tips Hydraulic Forum.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories