Feb . 11, 2025 14:50 Back to list

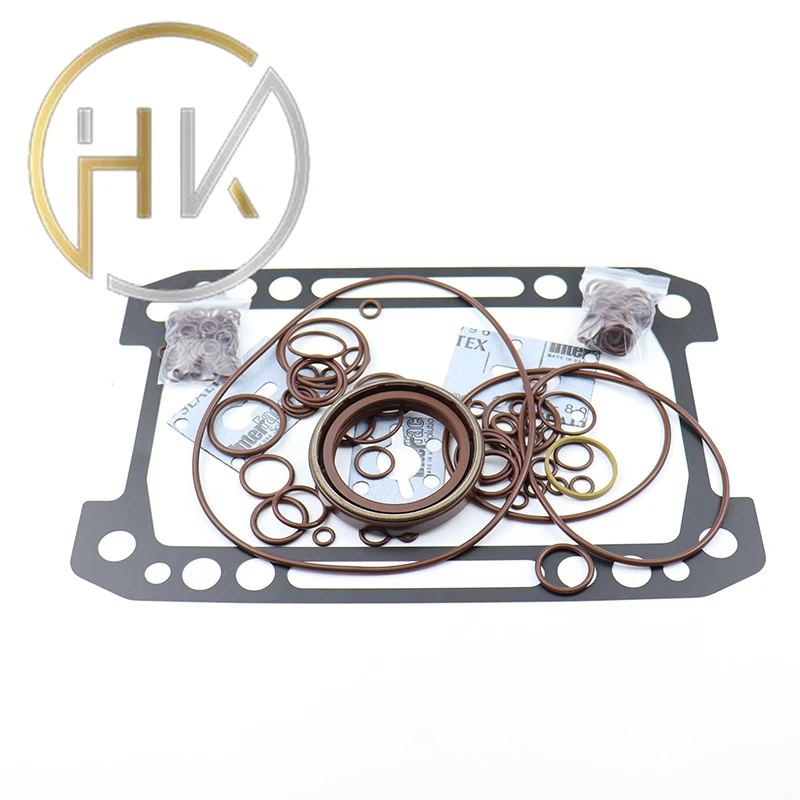

wiper ring piston

From an authoritativeness standpoint, experienced engine builders and mechanics emphasize the importance of regular inspection and maintenance of wiper rings. They advocate for routine engine inspections that allow for the assessment of wear patterns and any anomalies that might indicate underlying problems. With advanced diagnostic tools now available, mechanics can evaluate the condition of the wiper rings without the need for a complete engine teardown, saving time and resources while ensuring the engine remains in optimal condition. Trustworthiness in the provision of engine maintenance and component selection comes down to the knowledge and experience of the professionals involved. Customers and enthusiasts alike rely heavily on mechanics’ recommendations, making it imperative that these professionals are updated with the latest technology and component advancements. Continuous education and industry involvement are key components that ensure these professionals maintain a high degree of expertise, further cementing their status as reliable sources of information and service. In sum, wiper rings for pistons serve as pivotal elements in the quest for engine efficiency and performance. Their role, though sometimes undervalued, is foundational in sustaining the delicate equilibrium necessary for an engine's proper functioning. By nurturing a deeper understanding of their composition, design, and maintenance, professionals within the industry can not only extend the life of engines but also push the boundaries of what internal combustion engines can achieve. As technology continues to evolve, the craft of selecting and caring for wiper rings will undoubtedly advance, promising a future of even more efficient and powerful engines.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories