Dec . 21, 2024 01:03 Back to list

Seal Kit for White Hydraulic Motor Maintenance and Repair Solutions

Understanding the Importance of Hydraulic Motor Seal Kits

Hydraulic systems are a vital component in a wide variety of industrial machinery, agricultural equipment, and construction vehicles. Among these components, hydraulic motors play a critical role in converting hydraulic energy into mechanical energy. To ensure the optimal performance and longevity of hydraulic motors, the integrity of their seals is essential. This is where hydraulic motor seal kits come into play.

What is a Hydraulic Motor Seal Kit?

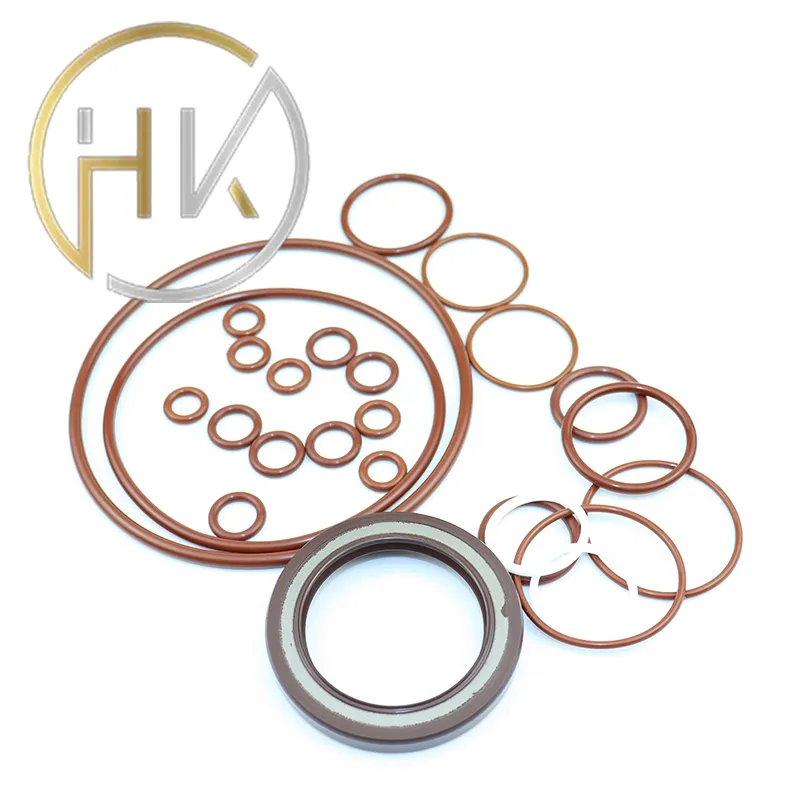

A hydraulic motor seal kit is a collection of sealing components designed to replace worn or damaged seals in hydraulic motors. These kits typically include O-rings, lip seals, backup rings, and various other rubber or polymer components that create a tight seal to prevent fluid leakage. The quality and compatibility of these seals directly affect the performance and reliability of the motor.

The Function of Seals in Hydraulic Motors

Seals in hydraulic motors serve several critical purposes

1. Preventing Fluid Leaks The primary function of seals is to keep hydraulic fluids contained within the motor. Fluid leaks can lead not only to a loss of efficiency but also to environmental hazards and increased operational costs.

2. Maintaining Pressure Seals help maintain the necessary pressure within hydraulic systems. A loss of pressure due to a seal failure can result in reduced performance or complete failure of the hydraulic motor.

3. Protecting Internal Components Seals act as barriers, preventing dust, dirt, and other contaminants from entering the motor. Contaminated hydraulic fluid can lead to wear and tear on internal components, ultimately shortening the lifespan of the motor.

4. Enabling Smooth Operation Well-functioning seals contribute to the smooth movement of the hydraulic motor. If seals are worn out, it can result in irregular operation, increased noise, and vibrations, compromising the system's functionality.

white hydraulic motor seal kit

Choosing the Right Seal Kit

When selecting a hydraulic motor seal kit, several factors should be considered

- Compatibility Ensure that the seal kit is compatible with the specific hydraulic motor model. Different manufacturers may use unique sizes and types of seals.

- Material Quality The material of the seals can significantly impact their durability and performance. It is essential to choose kits made from high-quality materials that can withstand temperature fluctuations, pressure, and exposure to various hydraulic fluids.

- Manufacturer Reputation Opting for trusted brands can often guarantee the quality and reliability of sealing components. Reputable manufacturers typically conduct rigorous testing to ensure their products meet industry standards.

Maintenance and Replacement

Regular maintenance plays a crucial role in the longevity of hydraulic motors. It is advised to inspect seals periodically for signs of wear, such as cracking, hardening, or deformation. Early detection of issues can prevent major failures and costly downtime.

When seals begin to show signs of wear, replacing the hydraulic motor seal kit is necessary. The replacement process should be approached carefully, following the manufacturer's guidelines to ensure proper installation. A correct installation is pivotal to create effective seals that will perform reliably under pressure.

Conclusion

In summary, hydraulic motor seal kits are essential components that ensure the efficiency and reliability of hydraulic systems. Understanding the importance of seals, choosing the right kits, and maintaining them can significantly enhance the performance of hydraulic motors. By investing in quality seal kits and prioritizing maintenance, operators can protect their equipment, reduce operational costs, and extend the life of their hydraulic systems. Whether in agriculture, construction, or industrial applications, the role of a dependable hydraulic motor seal cannot be overstated.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories