Dec . 16, 2024 03:08 Back to list

hydraulic ram oil seals

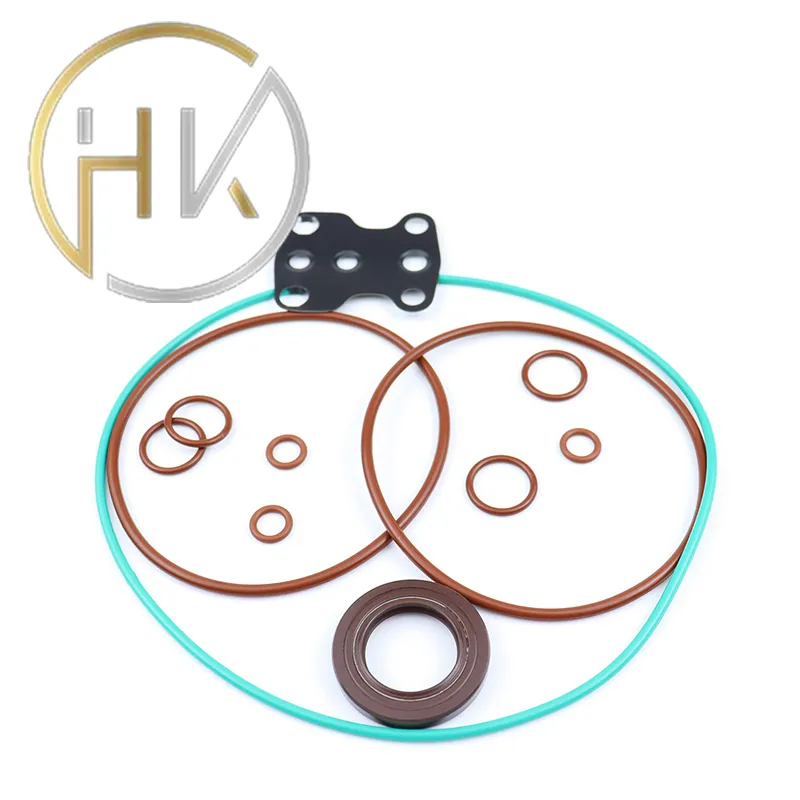

Understanding Hydraulic Ram Oil Seals

Hydraulic ram systems play a critical role in various industries, utilizing pressurized fluids to generate force and motion. A vital component of these systems is the hydraulic ram oil seal. These seals are essential for preventing fluid leakage, maintaining pressure, and ensuring the overall efficiency of the hydraulic system.

What is a Hydraulic Ram Oil Seal?

A hydraulic ram oil seal is designed to create a barrier that prevents hydraulic fluid from leaking out of the ram assembly while also keeping contaminants from entering. These seals typically consist of elastomeric materials, which are chosen for their flexibility, durability, and resistance to the chemicals present in hydraulic fluids. Common materials for hydraulic seals include nitrile rubber (NBR), polyurethane (PU), and fluoroelastomers, each offering specific advantages based on the operating conditions.

Importance of Hydraulic Oil Seals

The primary function of hydraulic oil seals is to maintain the integrity of the hydraulic system. A reliable seal is crucial for several reasons

1. Preventing Fluid Leakage Hydraulic systems operate under high pressure, and any leakage can lead to a drop in pressure, resulting in inefficiency or complete system failure. Oil seals ensure that the hydraulic fluid remains contained, preserving the system's functionality.

2. Protecting Internal Components Oil seals act as a first line of defense against dirt, dust, and other contaminants. These foreign particles can cause significant wear and tear on hydraulic components, leading to premature failure. By keeping contaminants at bay, oil seals help extend the lifespan of the hydraulic ram and its associated parts.

3. Maintaining Efficiency A well-functioning hydraulic system relies on consistent fluid flow and pressure. Oil seals help in maintaining this by providing effective sealing, which minimizes fluid loss and enhances the system's overall performance. An inefficient seal can result in wasted energy and increased operational costs.

Types of Hydraulic Ram Oil Seals

There are several types of hydraulic seals that can be used in ram applications, each designed for specific purposes

hydraulic ram oil seals

1. Rod Seals These seals are used where the hydraulic rod comes in and out of the cylinder. They are designed to withstand the dynamic conditions of reciprocating motion.

2. Piston Seals These seals are crucial in keeping the fluid from leaking around the hydraulic piston. They are built to manage high pressure and provide a reliable seal during the movement of the piston.

3. Guide Rings While not seals in the traditional sense, guide rings complement rod and piston seals by reducing friction and wear in hydraulic systems.

Factors to Consider When Choosing Oil Seals

When selecting a hydraulic ram oil seal, several factors must be considered

1. Operating Pressure and Temperature Different materials can handle various pressure levels and temperatures. Ensure that the selected seal material is compatible with your operational environment.

2. Fluid Compatibility The chemical composition of the hydraulic fluid can affect the seal's performance. Choose seals that are compatible with the specific hydraulic fluids in use.

3. Dynamic and Static Applications For applications involving movement (dynamic), different seals may be required compared to those that remain stationary (static). Understanding the nature of the application helps in making an informed choice.

4. Installation and Maintenance Proper installation is imperative to seal performance. Also, regular maintenance checks can prevent seal failure.

Conclusion

Hydraulic ram oil seals are indispensable in maintaining the efficiency and integrity of hydraulic systems. By understanding their functions, types, and the factors influencing their selection, industries can ensure optimal performance and longevity of their hydraulic systems. A reliable seal not only protects the apparatus but also contributes to the overall effectiveness of hydraulic applications, ultimately leading to safer and more cost-effective operations.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories