Dec . 01, 2024 03:48 Back to list

Excavator Seal Kit for Optimal Performance and Durability in Heavy Equipment Maintenance

Understanding Excavator Seal Kits Importance and Maintenance

Excavators are integral machines used in construction, mining, and various other industries. They are essential for moving earth and materials, digging, and performing other complex tasks. One of the critical components that ensure the efficient functioning of an excavator is the seal kit. In this article, we will delve into the importance of excavator seal kits, their components, and the maintenance practices that can help prolong their life.

What is an Excavator Seal Kit?

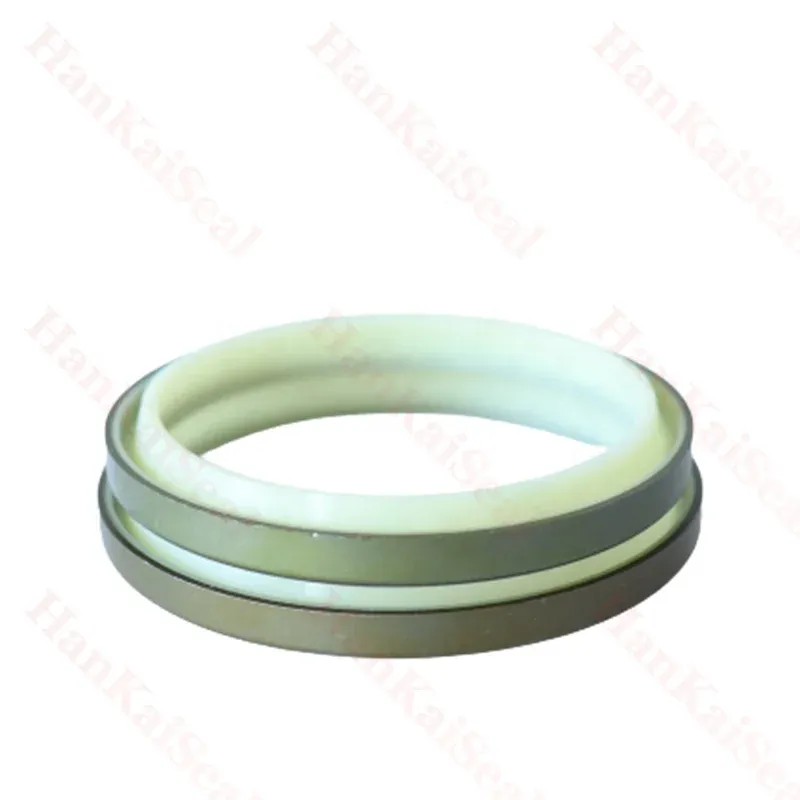

An excavator seal kit is a collection of seals that are essential for maintaining hydraulic systems within the excavator. These seals are critical for preventing hydraulic fluid from leaking out, which can lead to decreased efficiency, increased wear on components, and potential breakdown of the machinery. A typical seal kit includes O-rings, backup rings, rod seals, and piston seals, all of which work collectively to ensure that hydraulic actuators function correctly.

Importance of Seal Kits

1. Preventing Fluid Leaks One of the primary functions of seal kits is to prevent hydraulic fluid leaks. These leaks can not only waste valuable hydraulic fluid but can also lead to catastrophic failures in the hydraulic systems. A well-maintained seal kit ensures that the hydraulic functions operate smoothly without leakage, which is crucial for maintaining optimal performance.

2. Maintaining Pressure The hydraulic system requires a specific pressure to be effective. Damaged or worn seals can lead to a drop in pressure, affecting the overall performance of the excavator. By using a quality seal kit, operators can maintain consistent hydraulic pressure, enabling the excavator to perform its tasks efficiently.

3. Reducing Downtime Frequent leaks and failures often lead to costly downtime. By investing in a dependable excavator seal kit and ensuring it is regularly maintained, operators can minimize unexpected breakdowns and repairs, ultimately saving on operational costs and keeping projects on schedule.

4. Enhancing Longevity Regular maintenance of seal kits contributes to the longevity of the excavator itself. By ensuring that all seals are intact and functioning properly, operators can avoid additional wear on hydraulic components, which can lead to expensive repairs or even the need for premature replacement of the machine.

Components of Excavator Seal Kits

1. O-Rings These are the most common type of seals used in hydraulic systems. They are typically made from rubber or synthetic polymers and are employed to create a seal between two components.

excavator seal kit

2. Rod Seals Rod seals are designed to seal the hydraulic cylinder rod and prevent fluid from leaking out when the rod is extended or retracted.

3. Piston Seals These are used to seal the piston within the hydraulic cylinder, preventing fluid from flowing past the piston in a way that could cause inefficiency.

4. Backup Rings Backup rings support O-rings and serve to maintain the shape and position of the O-ring, especially under high pressure, ensuring a tighter seal.

Maintenance Tips for Excavator Seal Kits

1. Regular Inspection Regularly check the seals for signs of wear, such as cracking, tearing, or hardening. A visual inspection can help identify problems before they lead to leaks.

2. Hydraulic Fluid Quality Use high-quality hydraulic fluid, as recommended by the manufacturer. Contaminated or incorrect fluids can degrade seals more quickly.

3. Installation Practices Ensure that seals are installed correctly and that the surfaces are clean and free of debris before installation. Improper installation can lead to premature failure.

4. Monitor Performance Keep an eye on the performance of the excavator. Any signs of reduced power or efficiency may indicate a problem with the hydraulic system, which could be related to the seal kit.

5. Timely Replacement Follow the manufacturer's guidelines for replacing seal kits. Even the best kits will eventually degrade over time, so proactive replacement is key to preventing breakdowns.

Conclusion

Excavator seal kits are a vital component of hydraulic systems, playing a crucial role in ensuring the efficient and reliable operation of these powerful machines. By understanding their importance and adhering to proper maintenance practices, operators can significantly enhance the performance and longevity of their excavators, reducing costs and maximizing productivity on the job site. Regular attention to seal kits is not just an investment in machinery; it is an essential practice for any operator committed to excellence in construction and heavy equipment management.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories