Jan . 16, 2025 00:43 Back to list

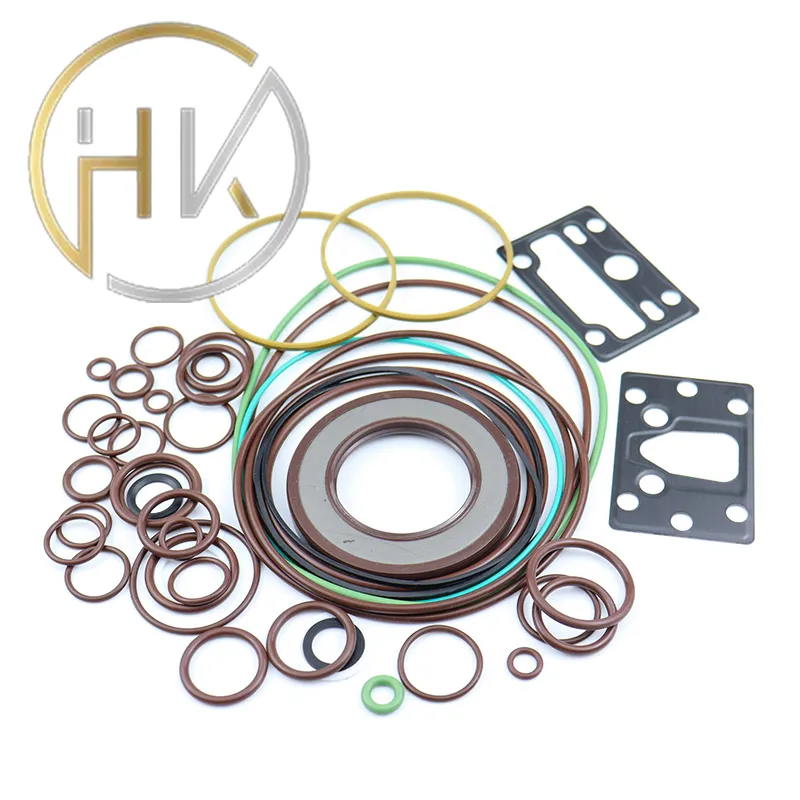

dust sealing

Field-tested methodologies of dust sealing continue to evolve, with innovations like nano-coatings offering cutting-edge solutions. Nano-coatings, applied to surfaces, create a thin, invisible barrier that repels dust particles and prevents accumulation. These advanced applications are gaining traction due to their effectiveness and durability, showing promise in both small-scale electronic devices and large industrial machinery. Backing these applications of dust sealing are rigorous scientific research and development efforts. Industry leaders consistently invest in innovation, driven by a need to enhance performance and efficiency. This commitment fuels advancements, ensuring that sealing solutions not only meet current demands but anticipate future challenges. Organizations like the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) set benchmarks for dust sealing capabilities, offering frameworks upon which industries can build and refine their approaches. Investment into dust sealing pays dividends not only in economic terms but also in sustainable practices. Companies adopting efficient dust sealing demonstrate corporate responsibility, reducing the environmental impact of their operations by minimizing waste and maximizing the life of their products. This aligns with global sustainability goals, adding a layer of trustworthiness and authority to those businesses committed to better practices. In conclusion, the importance of dust sealing cannot be overstated. Through a combination of in-depth expertise and cutting-edge technological solutions, industries are well-equipped to combat dust-related issues. This investment results in improved reliability, efficiency, and sustainability, all while maintaining high-quality standards and operational excellence. As the landscape of industrial demands continues to evolve, the role of dust sealing remains a cornerstone of innovative, responsible manufacturing practices.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories