Feb . 13, 2025 19:03 Back to list

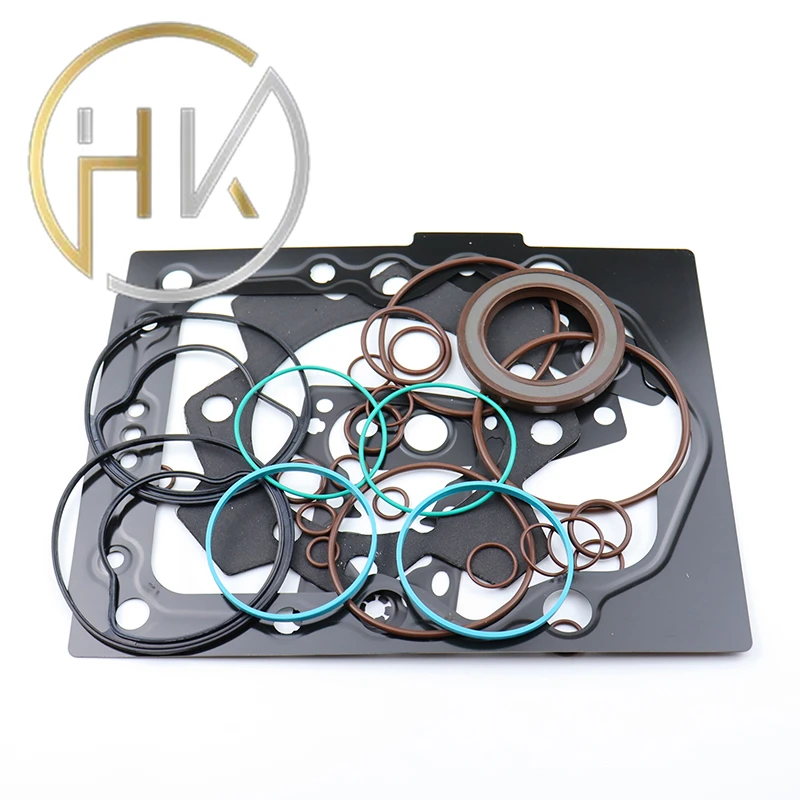

185*205*11 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

The manufacturing of these seals involves high-quality materials such as nitrile rubber, fluorocarbon, and silicone, each selected for their unique properties. Nitrile rubber, for instance, is renowned for its resistance to oil, fuel, and other chemicals, making it ideal for general-purpose applications. Fluorocarbon excels in applications requiring resistance to extreme temperatures and aggressive chemicals, while silicone is preferred for its excellent flexibility and temperature resistance. Expertise in selecting the right material based on the operational environment is crucial. For instance, in applications exposed to harsh chemicals or extreme temperatures, opting for a fluorocarbon variant of the 35x52x7 seal would be beneficial. On the other hand, nitrile rubber seals might be more appropriate for less demanding conditions, balancing cost-efficiency with satisfactory performance. Installation and maintenance best practices also play a pivotal role in maximizing the seal's lifespan. Before installation, it is essential to ensure that all mating surfaces are clean and free of debris. Using a compatible lubricant during installation can aid in reducing initial friction and wear. Regular inspection for signs of wear or damage is recommended, as is timely replacement to prevent system failures. The trustworthiness of using the 35x52x7 oil seal is further guaranteed by its compliance with international standards and rigorous quality testing. As these seals are often subjected to severe operational conditions, manufacturers conduct extensive testing to ensure they meet or exceed performance expectations. This commitment to quality ensures that users can trust the seals for critical applications across various industries. To sum up, the 35x52x7 oil seal stands out as a vital component across multiple industries, providing reliable sealing solutions that enhance operational efficiency and extend equipment lifespan. Its adaptability, coupled with advanced material options, offers engineering teams the confidence to maintain the highest standards of performance and reliability. Emphasizing the use of quality seals like the 35x52x7 can significantly impact the overall effectiveness of mechanical systems, underscoring the importance of selecting the right components in industrial applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories