Oct . 06, 2024 08:13 Back to list

35x47x7 oil seal

Understanding the 35x47x7 Oil Seal Importance, Applications, and Maintenance

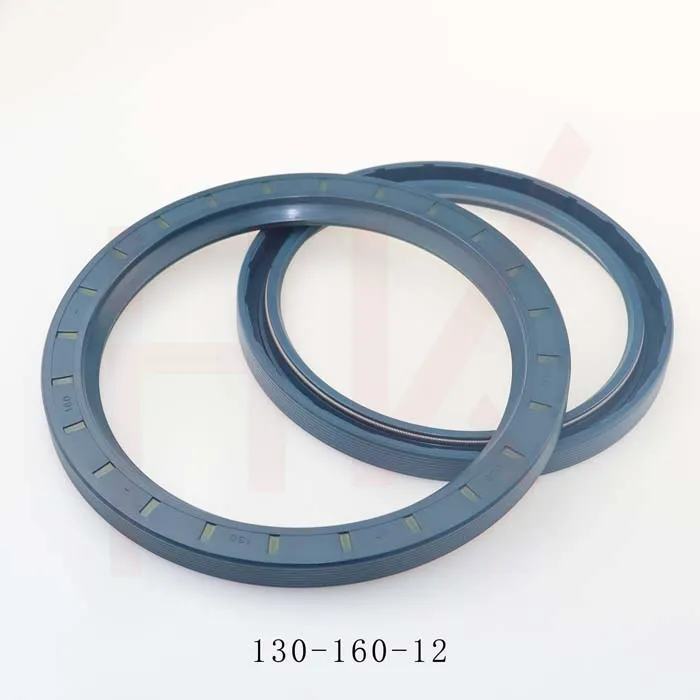

Oil seals, also known as oil gaskets or shaft seals, play a crucial role in various mechanical systems. The 35x47x7 oil seal is a specific size and type that is extensively utilized in numerous applications, including automotive, industrial machinery, and other equipment that requires the prevention of lubrication loss and the entry of contaminants. This article will explore the significance of the 35x47x7 oil seal, its applications, and key considerations for maintenance.

What is an Oil Seal?

An oil seal is a sealing device that is used to retain lubricants in machinery and prevent leakage. It also protects the components from dirt, dust, and other foreign particles. Oil seals are vital for the efficient operation of machinery, as they help maintain optimal lubrication, thereby reducing wear and tear on moving parts, improving performance, and extending the lifespan of the equipment.

Specifications of the 35x47x7 Oil Seal

The numbers in the designation 35x47x7 refer to the dimensions of the seal. Specifically

- 35 mm This is the inner diameter of the oil seal, which allows it to fit snugly onto a shaft of that size. - 47 mm This is the outer diameter of the oil seal, ensuring that it fits properly into the housing or bore of the equipment. - 7 mm This is the thickness of the oil seal, dictating how robust and durable the seal is under varying operational pressures and temperatures.

The combination of these dimensions makes the 35x47x7 oil seal suitable for a variety of applications, particularly where moderate pressures and temperatures are encountered

.Applications of the 35x47x7 Oil Seal

The 35x47x7 oil seal is commonly found in numerous applications due to its versatile design and effectiveness. Here are some of the most prevalent uses

1. Automotive Industry In vehicles, these seals are typically used in transmissions, differentials, and engine components to prevent oil leaks and protect the internal workings from grime and moisture.

2. Industrial Machinery Equipment such as pumps, motors, and compressors often utilize oil seals to ensure that lubricants remain inside and contaminants stay out, enhancing operational efficiency and longevity.

35x47x7 oil seal

3. Agricultural Equipment Tractors and other farming machinery rely on effective sealing to maintain proper lubrication, which is crucial in demanding agricultural environments.

4. Household Appliances Appliances like washing machines and dryers also utilize oil seals to prevent leaks and maintain operational integrity.

Importance of Quality in Oil Seals

When choosing oil seals, quality should never be compromised. A well-manufactured oil seal can significantly contribute to the performance and reliability of the machinery. High-quality materials, such as nitrile rubber or silicone, are often used to ensure durability and resistance to temperature fluctuations, chemicals, and wear.

Selecting the right oil seal not only ensures a proper fit but also minimizes the risk of premature failure. A failed oil seal can lead to oil leaks, which may cause catastrophic damage to machinery, resulting in costly repairs and downtime.

Maintenance and Replacement

Regular maintenance is essential in prolonging the life of oil seals and the machinery they protect. Here are a few tips

- Inspection Regularly check for signs of wear, including cracks, tears, or hardening. Early detection can prevent severe damage to the machinery. - Lubrication Ensure that the system is adequately lubricated, which can help reduce friction and wear on the oil seal itself.

- Proper Installation Ensure that the oil seal is installed correctly. Misalignment can lead to premature failure.

- Replacement If an oil seal starts to leak, it is crucial to replace it promptly to prevent further damage.

Conclusion

The 35x47x7 oil seal is a critical component in various industrial and automotive applications, serving to protect machinery from leaks and contamination. By understanding its specifications, applications, and the importance of proper maintenance, operators can ensure that their equipment runs efficiently and remains in good working condition for years to come. Ultimately, selecting high-quality oil seals and adhering to best practices in maintenance can significantly enhance performance and reliability, making it a worthwhile investment in any operational setting.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories