ડીસેમ્બર . 04, 2024 09:29 Back to list

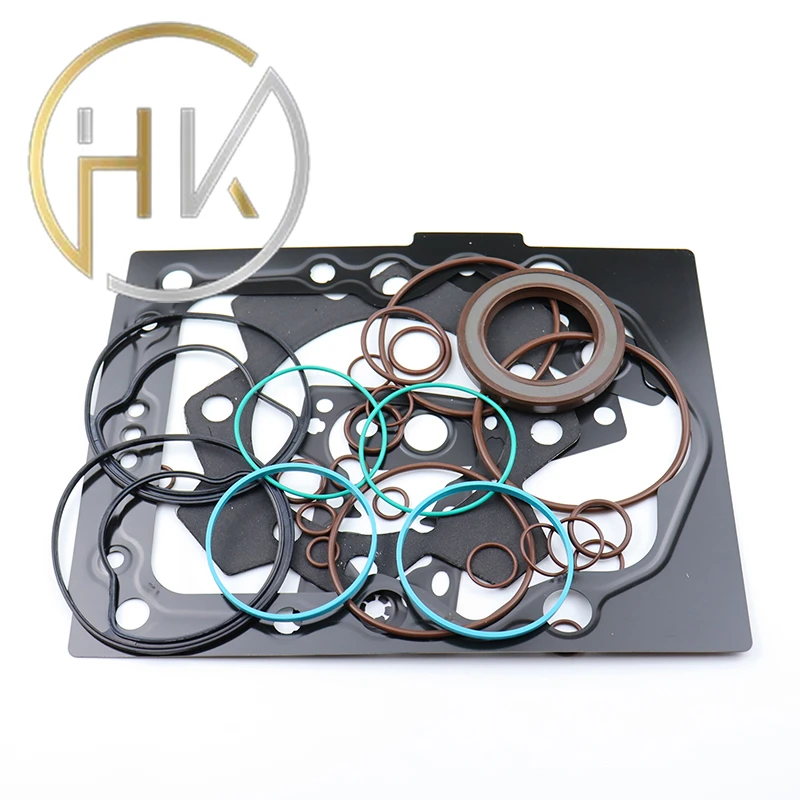

skeleton oil seal

Understanding Skeleton Oil Seals Function, Design, and Applications

Skeleton oil seals are vital components in various mechanical systems, primarily serving to prevent the leakage of lubricants and the ingress of contaminants. These seals are crucial for the efficient operation of machinery, particularly in automotive, industrial, and aerospace applications. In this article, we will explore the function, design features, and applications of skeleton oil seals, highlighting their importance in maintaining equipment reliability and longevity.

Function of Skeleton Oil Seals

At their core, skeleton oil seals are employed to create a barrier between moving parts and the external environment. They are designed to seal the gaps in machinery where a shaft exits a housing, thereby preventing the escape of lubricating oils or greases. Additionally, they serve to block dirt, dust, and moisture from entering the system, which could lead to wear and tear, corrosion, or even catastrophic failure of the machinery.

The effectiveness of a skeleton oil seal in maintaining a lubricant's integrity and shielding against contaminants is crucial for the performance of rotating equipment. Over time, failure to properly seal a component can result in decreased efficiency, increased maintenance costs, and even unplanned downtime.

Design Features

Skeleton oil seals are typically composed of two main components a metal or synthetic skeleton and a sealing lip. The skeleton provides structural support, while the sealing lip ensures a tight fit against the shaft. Here are some key design features often found in skeleton oil seals

1. Material Composition Skeleton oil seals are generally made from elastomers such as nitrile (NBR), fluorocarbon (FKM), or silicone, depending on the application's temperature and chemical resistance requirements. The choice of material influences the seal's durability and performance under various operational conditions.

2. Lip Geometry The design of the sealing lip is critical to the performance of the oil seal. Different lip configurations (such as single or double lip seals) can be employed to enhance sealing capabilities, improve wear resistance, and manage pressure differentials effectively.

3. Coating Many skeleton oil seals come with various coatings to enhance their performance. These coatings may provide additional resistance to chemicals, extreme temperatures, or abrasive materials.

skeleton oil seal

4. Spring Mechanism Some skeleton oil seals incorporate a garter spring that is positioned on the sealing lip. This spring helps maintain a consistent contact force between the seal and the shaft, ensuring optimal sealing even when there is shaft misalignment or dimensional changes due to thermal expansion.

Applications of Skeleton Oil Seals

Skeleton oil seals are used across a range of industries due to their reliability and efficiency. Here are some specific applications

1. Automotive Industry Skeleton oil seals are commonly found in engines, transmissions, differential housings, and other critical components. They help maintain proper oil levels and prevent leakage, ensuring smooth operation and extending the life of the vehicle.

2. Industrial Equipment In manufacturing and heavy machinery, skeleton oil seals play a fundamental role in ensuring the longevity of bearings and gears. They help maintain lubrication while protecting against dust, dirt, and moisture, which can impair function.

3. Aerospace Engineering The aerospace sector demands high-performance sealing solutions due to the extreme conditions encountered during operation. Skeleton oil seals are critical in aircraft engines and landing gear systems, where failure prevention is paramount.

4. Household Appliances Even in everyday items such as washing machines and refrigerators, skeleton oil seals can be found. They help prevent leaks and maintain efficiency, contributing to the overall performance of these devices.

Conclusion

Skeleton oil seals are essential components in countless mechanical systems. By effectively sealing lubricants and blocking contaminants, they extend the life of machinery and reduce maintenance needs. Their versatile design accommodates a range of materials and applications, making them a go-to solution for engineers and manufacturers alike. As industries continue to evolve, the demand for reliable and efficient sealing solutions like skeleton oil seals will only increase, underscoring their importance in modern technology. Understanding their function, design features, and applications is crucial for anyone involved in machinery maintenance and engineering.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories