નવેમ્બર . 18, 2024 08:45 Back to list

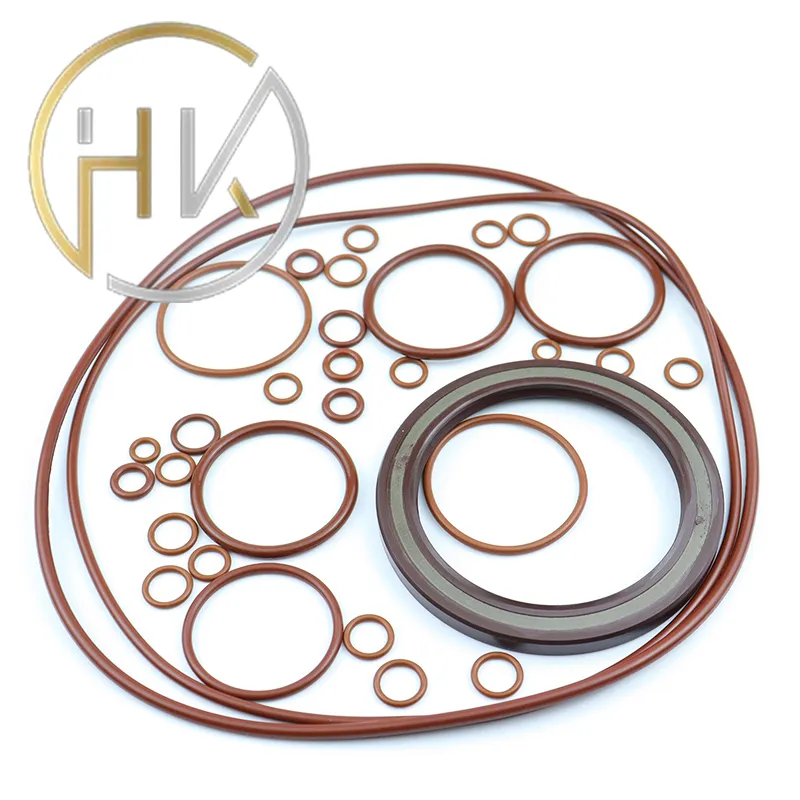

Pallet Jack Seal Kit Essential for Optimal Performance and Maintenance

The Importance of Seal Kits for Pallet Jacks A Comprehensive Overview

Pallet jacks are essential tools in warehouses, distribution centers, and manufacturing environments. They facilitate the transport of heavy loads by allowing operators to lift pallets off the ground with minimal effort. However, like any mechanical equipment, pallet jacks are subject to wear and tear, which can lead to diminished performance if not addressed promptly. One vital component in maintaining the efficiency and safety of a pallet jack is the seal kit.

A seal kit for a pallet jack is designed to replace worn-out or damaged seals in the hydraulic system. Seals are critical for preventing hydraulic fluid leaks, ensuring smooth operation, and maintaining optimal lifting capabilities. Over time, seals can wear due to friction, extreme temperatures, or exposure to harsh chemicals, leading to leaks that can compromise the pallet jack's functionality and safety.

Why Use a Seal Kit?

1. Prevent Hydraulic Fluid Leaks The primary purpose of a seal kit is to prevent leaks within the hydraulic system. When hydraulic fluid leaks, it can lead to a significant loss of power, making it difficult to lift or lower loads. By replacing old seals with new ones, you can ensure that the hydraulic system remains efficient and responsive, which is crucial for daily operations.

2. Extend Equipment Life Regular maintenance is key to extending the life of any equipment, and pallet jacks are no exception. By investing in a seal kit and performing routine replacements, you can significantly prolong the life of your pallet jack. This not only saves money in the long run but also reduces downtime caused by equipment failure.

seal kit for pallet jack

3. Enhance Safety Safety is paramount in any workplace, especially when dealing with heavy loads. A malfunctioning pallet jack can pose risks to operators and other staff members. Leaking hydraulic fluid can lead to unstable lifting, increasing the likelihood of accidents. By ensuring that your pallet jack is equipped with a properly functioning seal kit, you enhance overall safety on the job.

4. Cost-Effectiveness Purchasing a seal kit is a cost-effective solution compared to the potential costs associated with replacing an entire pallet jack. By performing preventive maintenance and replacing seals as needed, businesses can save significant amounts on machinery replacement and repair costs.

Choosing the Right Seal Kit

When selecting a seal kit for your pallet jack, it's essential to consider compatibility with your specific model, as different pallet jacks may require different seals. Additionally, look for kits made from high-quality materials that can withstand harsh working conditions. Some manufacturers offer seal kits that are designed for easy installation, which can save time and labor costs.

In conclusion, seal kits play a crucial role in maintaining pallet jacks, ensuring their optimal operation, extending equipment life, and enhancing workplace safety. Regular maintenance and timely replacement of seals not only improve efficiency but also represent a sound investment for any business using pallet jacks. By prioritizing the health of your equipment, you can keep your operations running smoothly and safely.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories