ફેબ્રુવારી . 04, 2025 02:17 Back to list

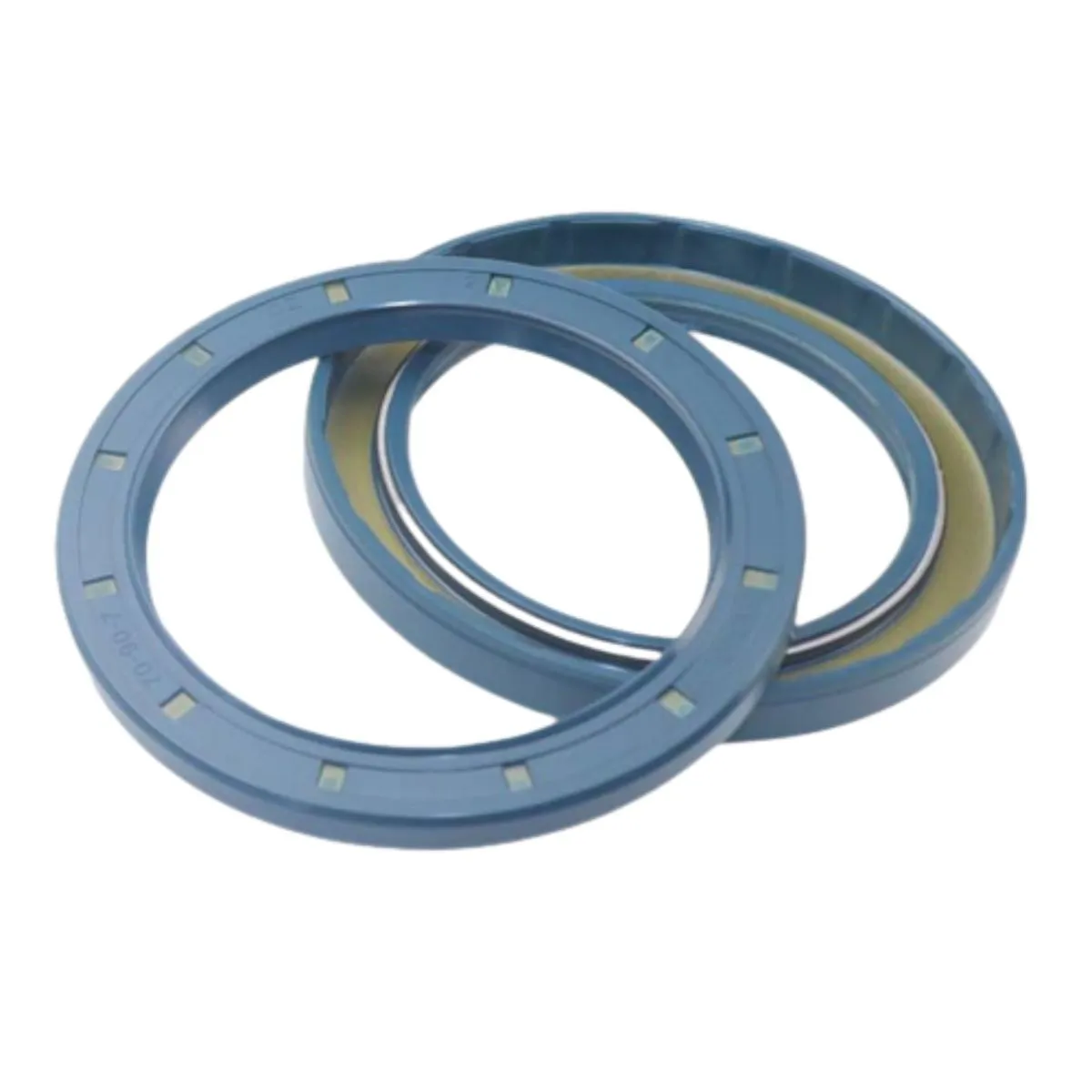

rear hub seal

However, even the finest seals can falter if improper installation occurs. Expert mechanics like Erika Thompson, who has been spearheading automotive workshops for over 15 years, emphasize, When installing, attaining the right fit is paramount to avert eventual leaks. Always ensure the surfaces are impeccably clean and unblemished before application. Indeed, a meticulous installation process, coupled with periodic inspections, can dramatically extend the life expectancy of the hub seals. Additional tendencies to consider involve the seal's compatibility with the vehicle's make and model. Customized solutions, although potentially pricier, provide the optimal fit, thereby reducing the propensity for seal failure. Many top-tier manufacturers offer tailored options, ensuring both product reliability and customer satisfaction. In terms of market reliability, considering brands with an established track record is advisable. Organizations that provide robust warranties and readily available customer service channels rank higher in consumer trust, which is crucial when investing in automotive components that directly affect safety. In conclusion, while rear hub seals may appear as mere peripheral components within the vehicular ecosystem, their role is pivotal. Ensuring you choose the right product, understanding its material benefits, installation nuances, and brand reputation can make a substantial difference in the vehicle's overall performance and safety. Investing in high-quality rear hub seals will not only enrich your driving experience but assure the peak upkeep of your vehicle over the years.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories