ઓક્ટોબર . 31, 2024 14:03 Back to list

Understanding Gearbox Seals and Their Importance in Engine Performance and Longevity

Understanding Gearbox Seals Importance and Applications

Gearbox seals are critical components that play an essential role in the operation and longevity of gearboxes in various machinery and vehicles. These seals are designed to prevent the leakage of lubricant fluids from the gearbox while also protecting the internal components from contamination by dirt, dust, and other foreign particles. Given their importance, it is vital to understand the various types of gearbox seals, their applications, and maintenance practices.

Gearboxes are responsible for transferring power and torque from the engine to the wheels in vehicles, as well as in a variety of industrial machines. Within the gearbox, lubricant is crucial for reducing friction and wear among moving parts, ensuring smooth operation, and preventing overheating. However, this lubricant is susceptible to leakage, which can lead to severe damage to the gearbox if not addressed. This is where gearbox seals come into play.

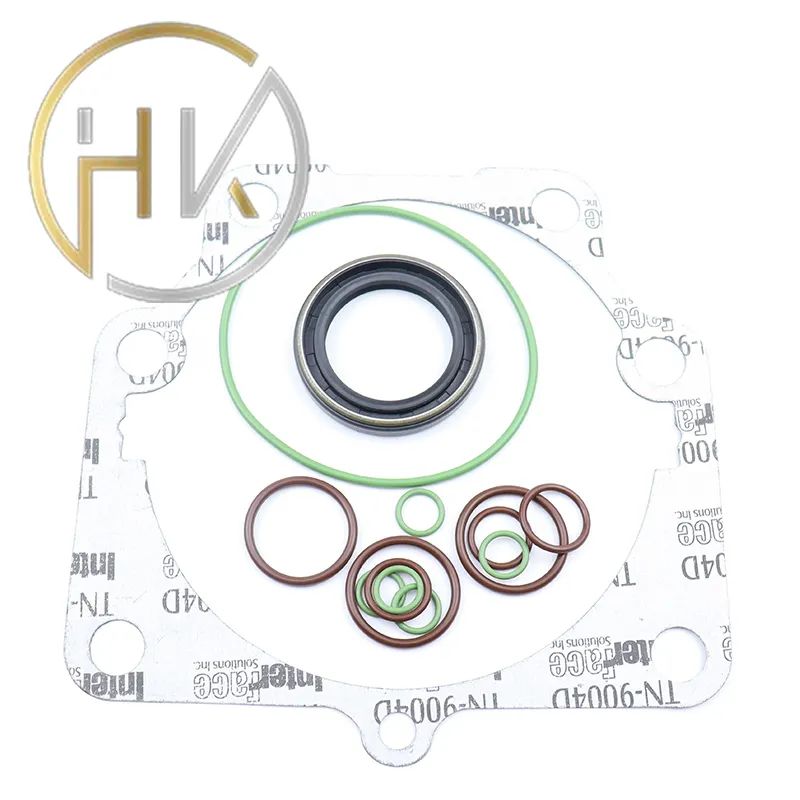

There are various types of gearbox seals, each designed for specific applications. The most common types include lip seals, O-rings, and cassette seals. Lip seals, often made from elastomers, feature a flexible lip that fits against a stationary part, creating a barrier to prevent fluid loss. O-rings, circular in shape, provide a tight seal when compressed between two surfaces. Cassette seals, which consist of multiple sealing elements, are ideal for more complex gearbox designs, ensuring that various fluid paths remain isolated.

gearbox seals

In heavy machinery and automotive applications, ensuring the integrity of gearbox seals is vital. Regular wear and tear can lead to seal degradation, leading to leaks that could compromise the gearbox’s functionality. Therefore, routine inspections and maintenance are essential. Signs of seal failure may include fluid leakage, unusual noises from the gearbox, or changes in performance. Addressing these issues promptly can prevent more extensive damage and costly repairs.

The materials used for gearbox seals are also of significance. Modern seals are typically made from synthetic rubber compounds that can withstand extreme temperatures and pressures, contributing to their durability. Selecting the right seal material is critical, as it must suit the specific operational environment of the gearbox.

In conclusion, gearbox seals are a fundamental aspect of maintaining the efficiency and reliability of gearboxes in various machinery. By preventing lubricant loss and protecting against contamination, they play a crucial role in extending the lifespan of these components. Regular inspection, proper material selection, and timely maintenance are key to ensuring that gearbox seals function optimally, thereby minimizing downtime and enhancing performance. For anyone involved in machinery maintenance or automotive repair, a thorough understanding of gearbox seals is essential for delivering quality work and ensuring optimal machine operation.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories