ડીસેમ્બર . 16, 2024 15:57 Back to list

Alternative Seals for 20% 2035 7 Oil Applications and Their Benefits

Understanding the Importance of the 20% 35% 7% Oil Seal in Modern Applications

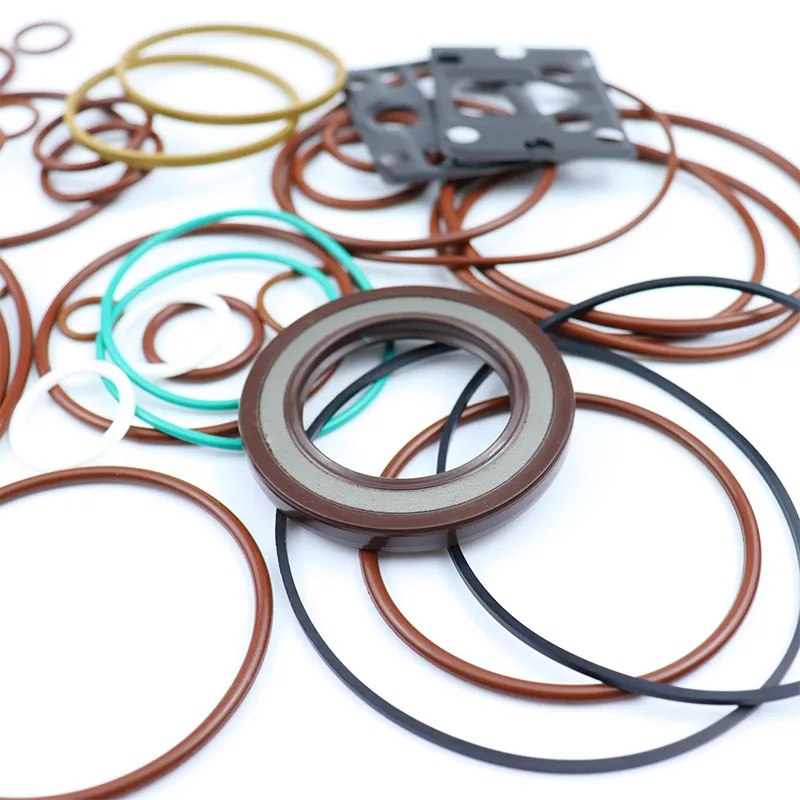

In the realm of engineering and machinery, components such as seals play a critical role in ensuring the smooth functioning of various systems. Among these, the 20% 35% 7% oil seal stands out due to its specific design and applications. Oil seals are crucial in preventing the leakage of lubricants and protecting machinery from external contaminants, thereby enhancing the longevity and efficiency of equipment. This article delves into the significance of the 20% 35% 7% oil seal, its construction, applications, and maintenance.

What is a 20% 35% 7% Oil Seal?

The terminology “20% 35% 7%” generally refers to the materials and composition of the oil seal. This fraction might indicate the proportions of different materials used in the oil seal, pertaining largely to the rubber compounds that contribute to its effectiveness. Understanding these proportions is essential for selecting the appropriate seal for a given application.

In general, oil seals are composed of elastomers such as Nitrile (Buna-N), Silicone, Viton, or Polyurethane. The ratios indicate the blend of materials that allow the seal to withstand various conditions, such as extreme temperatures, chemical exposure, and pressure. In this context, the percentages could represent Nitrile rubber for oil resistance, a higher percentage of silicone for heat resistance, and a smaller fraction of another material for added durability and flexibility, culminating in an efficient sealing solution.

Key Benefits of the 20% 35% 7% Oil Seal

1. Effective Lubrication Retention One of the primary functions of an oil seal is to maintain lubricant integrity. The 20% 35% 7% oil seal excels in preventing oil leaks, ensuring that machinery continues to operate efficiently without the risk of losing essential lubricants.

2. Contamination Prevention These oil seals also act as barriers against dirt, dust, and moisture, which are detrimental to machinery. By maintaining a clean environment, they help avoid wear and tear, thereby prolonging the life of the equipment.

3. Temperature Resilience The specific material composition of the 20% 35% 7% oil seal allows it to operate effectively under a wide range of temperatures. This feature is particularly important in industrial applications where machinery may be exposed to heat and cold, thus maintaining optimal performance.

20 35 7 oil seal

4. Cost-Efficiency While investing in high-quality seals may seem costly initially, the long-term benefits—such as reduced maintenance costs and extended service life—make them a worthwhile investment. The 20% 35% 7% oil seal contributes to significant savings over time by minimizing downtime and maintenance needs.

Applications of the 20% 35% 7% Oil Seal

This versatile oil seal finds applications across various industries, including automotive, manufacturing, and aerospace

- Automotive Industry Oil seals are vital in engines, transmissions, and differentials, playing a crucial role in fluid retention and preventing oil leaks.

- Industrial Machinery In manufacturing settings, where heavy machinery operates continuously, the 20% 35% 7% oil seal is essential for ensuring that lubricants remain where they are needed without contamination.

- Aerospace The aviation sector requires seals that can withstand extreme conditions. The properties of the 20% 35% 7% oil seal make it suitable for use in aircraft engines and landing gear systems, where reliability is paramount.

Maintaining the 20% 35% 7% Oil Seal

To ensure the longevity and efficacy of the 20% 35% 7% oil seal, regular inspection and maintenance are necessary. Operators should routinely check for signs of wear, such as cracking or deformation. Additionally, ensuring compatibility between the seal and the lubricants used can enhance performance and prevent premature failure.

In conclusion, the 20% 35% 7% oil seal represents an important advancement in seal technology, offering durability, efficiency, and reliability across numerous applications. By understanding its construction and benefits, industries can take proactive steps to implement the right sealing solutions, significantly improving operational efficiency and machinery lifespan. As technology continues to advance, the development of even more specialized seals is likely, shaping the future of engineering and industrial design.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories