Out . 20, 2024 10:41 Back to list

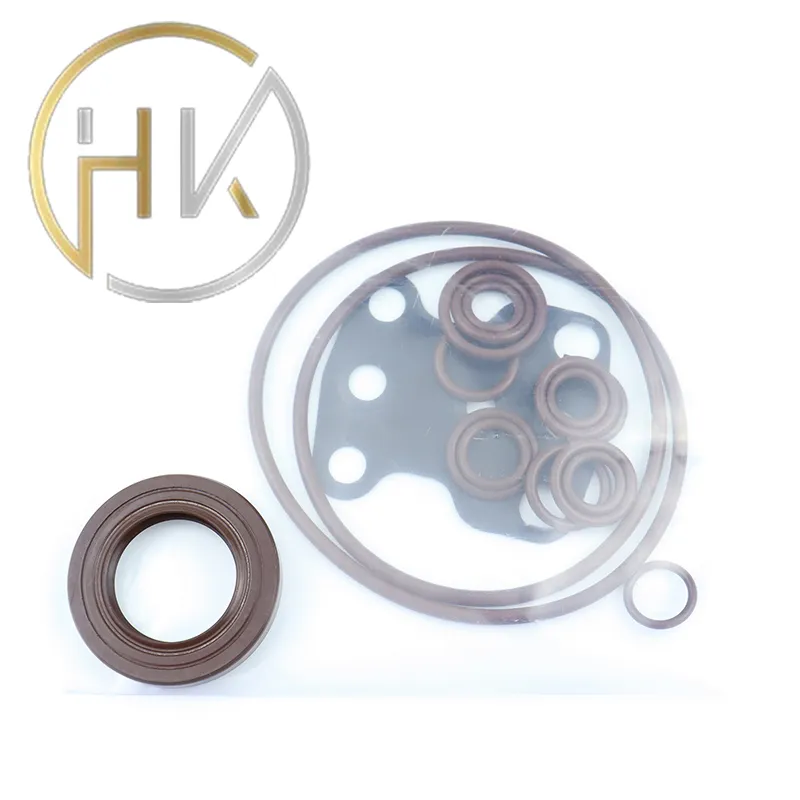

wiper seal hydraulic cylinder

Wiper Seal for Hydraulic Cylinders Essential Components for Efficient Performance

Hydraulic cylinders are vital components in various industries, from construction and automotive to aerospace and manufacturing. They convert hydraulic energy into mechanical force, facilitating smooth and controlled movements of machinery. Within the intricate design of hydraulic cylinders, wiper seals are pivotal in enhancing performance, ensuring longevity, and protecting the internal components from contamination.

What is a Wiper Seal?

A wiper seal, also known as a scraper seal, is designed to prevent dirt, dust, and other contaminants from entering a hydraulic cylinder. It typically sits at the outer end of the cylinder, effectively working to maintain the cleanliness of the hydraulic fluid, which is critical for optimal operation. The primary function of the wiper seal is to engage with the piston rod as it extends and retracts, scraping off debris that may adhere to the rod’s surface.

Function and Importance

The key role of a wiper seal goes beyond simple contamination prevention. By keeping impurities out of the hydraulic cylinder, wiper seals contribute significantly to the overall efficiency and longevity of the hydraulic system. Contaminants can cause wear on internal components, leading to premature failure of seals, o-rings, and even the entire hydraulic cylinder. The cost of replacing these parts can be high, not to mention the downtime incurred from equipment failure.

Additionally, a well-functioning wiper seal aids in maintaining the hydraulic pressure and reduces the risk of leaks. In hydraulic systems, even a small leak can result in significant performance issues and safety concerns. Therefore, by preventing the ingress of foreign materials, wiper seals play a critical role in maintaining the integrity of hydraulic machinery.

Materials Used

wiper seal hydraulic cylinder

Wiper seals are available in various materials, each chosen based on specific applications and operational environments. Common materials include polyurethane, nitrile rubber, and silicone, which offer different benefits in terms of temperature resistance, flexibility, and durability. For instance, polyurethane wiper seals provide excellent resistance to wear and tear, making them ideal for high-performance applications, while nitrile rubber wiper seals are more suited for environments where oil and fuel are present.

Design Considerations

The design of a wiper seal is crucial for its effectiveness. Factors such as the seal profile, hardness, and size must be carefully considered to ensure a proper fit within the hydraulic cylinder. Engineers must account for the operational pressure and temperature ranges to select the most suitable wiper seal. A properly designed wiper seal will ensure a tight fit around the piston rod, enabling it to wipe effectively with each stroke and preventing the build-up of dirt and grime.

Installation and Maintenance

Proper installation and maintenance of wiper seals are essential for maximizing their performance. During installation, it's critical to avoid damaging the seals, as even minor imperfections can lead to failure. Additionally, periodic inspections of the wiper seals should be carried out to check for signs of wear or damage. If any issues are detected, timely replacement is necessary to prevent further damage to the hydraulic system.

Conclusion

The wiper seal is a small yet vital component of hydraulic cylinders. Its primary function is to protect the cylinder from contamination, ensuring smooth operation and extending the lifespan of the equipment. With various materials and designs available, selecting the right wiper seal for the specific application is crucial. By understanding the importance of wiper seals and committing to proper installation and maintenance practices, industries can enhance the efficiency and reliability of their hydraulic systems. Overall, investing in quality wiper seals can lead to significant long-term savings and improved performance across a range of applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories