Dùbh . 22, 2024 21:52 Back to list

Hydraulic Cylinder Seal Kit Selection and Maintenance Tips for Optimal Performance

Understanding Hydraulic Cylinder Seal Kits

Hydraulic systems are integral components in various industries, including manufacturing, construction, and transportation. Among the critical components of these systems are hydraulic cylinders, which convert hydraulic energy into mechanical force. To ensure that these cylinders function efficiently and have a long lifespan, seal kits play a vital role. In this article, we will explore what hydraulic cylinder seal kits are, their importance, types, and maintenance tips.

What Are Hydraulic Cylinder Seal Kits?

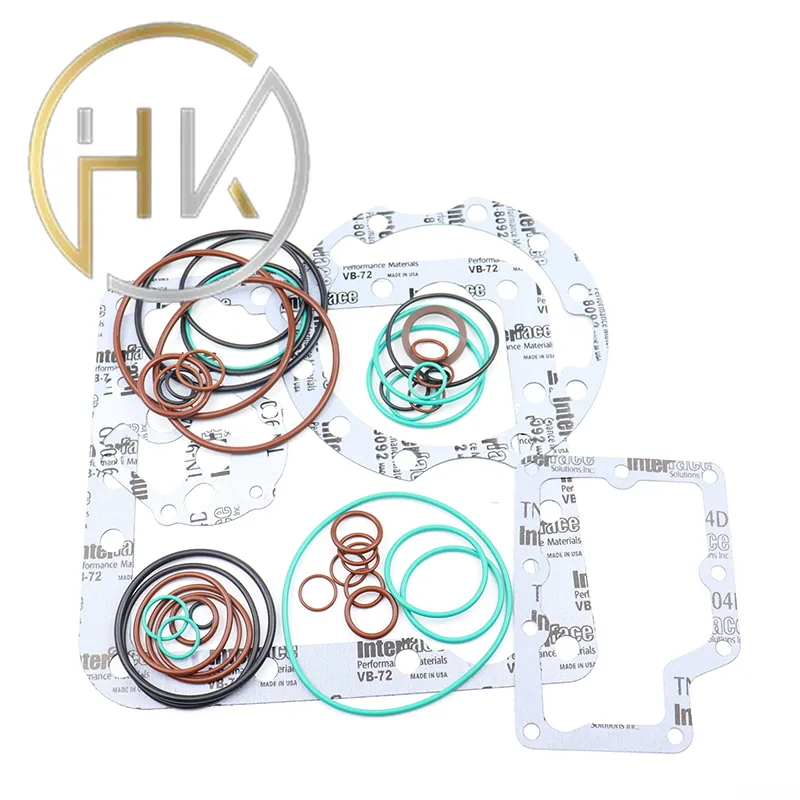

Hydraulic cylinder seal kits are assemblies of seals and other components designed to prevent fluid leaks, maintain pressure, and ensure the efficient operation of hydraulic cylinders. These kits typically come with a variety of seals, including O-rings, rod seals, piston seals, and wipers. Each type of seal has a specific function and is made from materials that can withstand different hydraulic fluids and environmental conditions.

Importance of Hydraulic Cylinder Seal Kits

1. Leak Prevention One of the primary functions of seal kits is to prevent hydraulic fluid from leaking out of the cylinder. Leakage can lead to a drop in pressure, resulting in inefficient operation and increased wear on the components.

2. Pressure Retention Seal kits help maintain the necessary hydraulic pressure within the cylinder. This pressure is essential for the proper operation of machinery and equipment that rely on hydraulic systems.

3. Protection Against Contamination The seals in a hydraulic cylinder seal kit also protect the internal components from contaminants such as dirt, dust, and moisture. Keeping these contaminants out is crucial for maintaining the integrity of the hydraulic fluid and the components.

4. Extended Equipment Life By maintaining proper sealing and preventing wear and tear, high-quality seal kits contribute to the extended lifespan of hydraulic cylinders and, by extension, the machinery they are part of.

Types of Seals in Hydraulic Cylinder Seal Kits

Hydraulic cylinder seal kits contain various seals, each with specific roles

- Rod Seals These are designed to prevent fluid from leaking out along the piston rod. They need to be durable and resistant to wear since they endure dynamic movement.

- Piston Seals Positioned on the piston itself, these seals ensure that hydraulic fluid is contained within the cylinder, providing the necessary force for operation.

- Wipers Also known as dirt seals or scrapers, wipers are located at the outer end of the cylinder and prevent contaminants from entering the cylinder.

hydraulic cylinder seal kits

- O-Rings These are versatile seals used in various parts of the hydraulic system. They can be used to seal connections and joints.

Choosing the Right Seal Kit

Selecting the correct hydraulic cylinder seal kit is crucial for your system's performance. Here are some factors to consider

1. Compatibility Ensure that the seal kit is compatible with the specific hydraulic cylinder model you are using. Different models may require different sizes and types of seals.

2. Material The material of the seals is important for performance. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and polyurethane (PU), each suited for different applications and fluid types.

3. Pressure and Temperature Ratings Be aware of the pressure and temperature specifications of your hydraulic system. The seal kit you choose should be able to withstand these conditions to ensure reliable operation.

Maintenance Tips for Hydraulic Seal Kits

1. Regular Inspection Frequently inspect hydraulic cylinders for signs of wear or damage in the seal kits. Early detection can prevent costly downtime and repairs.

2. Proper Installation Ensure that seals are installed correctly to avoid misalignment, which can lead to premature wear and leakage.

3. Clean Environment Keep the working environment clean to minimize contamination risks. Use wipers effectively to prevent dirt and debris from entering the cylinder.

4. Use Appropriate Fluids Always use hydraulic fluids that are compatible with the seals to avoid chemical reaction that could degrade them over time.

Conclusion

Hydraulic cylinder seal kits are essential for the efficient operation of hydraulic systems. By understanding their importance, the types of seals involved, and adhering to maintenance practices, businesses can enhance the performance and longevity of their hydraulic equipment. Investing in high-quality seal kits and proper maintenance will ultimately result in improved efficiency and reduced operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories