Samh . 07, 2024 22:16 Back to list

Understanding the Importance of Cassette Oil Seals in Automotive Applications

Understanding Cassette Oil Seals Importance and Functionality

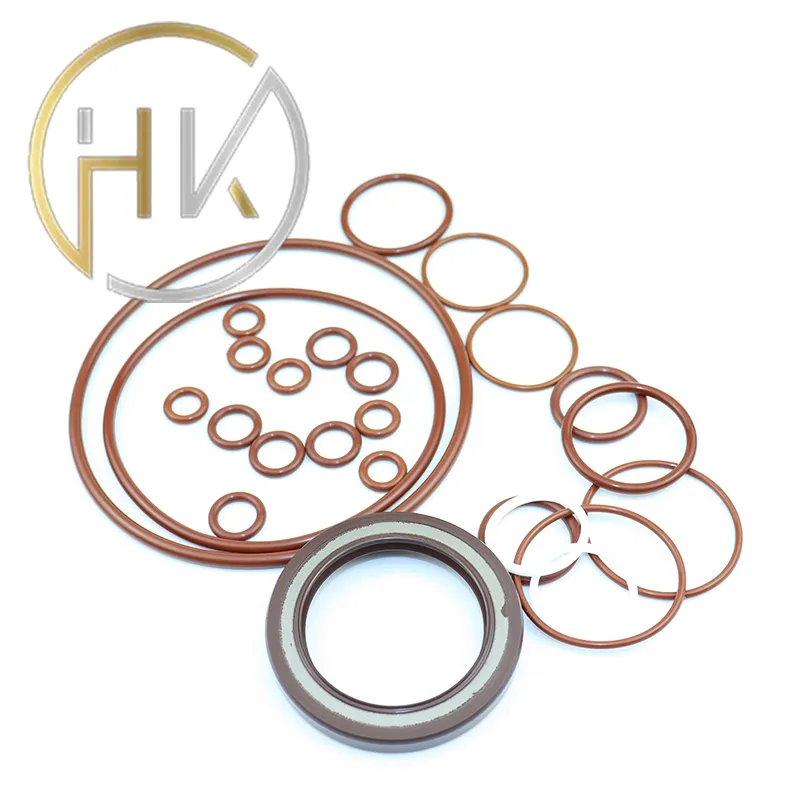

A cassette oil seal, often referred to simply as an oil seal, is a critical component used in various machinery and automotive applications. Its primary function is to prevent the leakage of lubricants while protecting the internal components from dust, dirt, and other contaminants. Understanding the design, function, and significance of cassette oil seals can help in enhancing the longevity and performance of machinery, as well as improving maintenance practices.

What is a Cassette Oil Seal?

A cassette oil seal is a mechanical seal typically made from rubber or synthetic materials. It is designed to fit into a cylindrical housing and comprises several key features, including a sealing lip, a dust lip, and a spring mechanism. The sealing lip creates a tight seal around the shaft, while the dust lip protects the sealing lip from external contaminants. The spring serves to maintain the appropriate pressure against the shaft, ensuring a secure fit and preventing oil from leaking out.

The Importance of Cassette Oil Seals

Cassette oil seals play a vital role in the functioning of various machines and vehicles. Below are some key reasons why they are crucial

1. Leak Prevention One of the primary roles of a cassette oil seal is to prevent the seepage of oils and lubricants from internal systems. Leaking oil not only reduces the efficiency of the machine but can also lead to more significant damage over time due to insufficient lubrication.

2. Contamination Barrier Cassette oil seals act as a barrier to dust, dirt, and other particulates that could enter the machinery. Contaminants can lead to increased wear and tear on moving parts, reducing their operational efficiency and lifespan.

3. Reduced Downtime By preventing leaks and contamination, oil seals contribute to the reliability of machinery and vehicles. This reliability translates into reduced maintenance needs and decreased downtime, allowing for more efficient operations.

cassette oil seal

4. Cost-Effective Investing in quality cassette oil seals can lead to considerable savings in the long run. By avoiding costs associated with oil loss, wear on components, and potential machinery replacements, organizations can allocate their resources more effectively.

Installation and Maintenance

Correct installation of cassette oil seals is essential for optimal performance. Here are some tips to ensure proper installation

1. Clean the Installation Area Before installing a cassette oil seal, ensure that the seating area is clean and free of debris. Dirt and impurities can compromise the seal's effectiveness.

2. Check Compatibility Verify that the oil seal is compatible with the specific machinery or vehicle. Standards such as size, material, and design should be considered to ensure proper performance.

3. Use Proper Tools Using the right installation tools can prevent damage to the seal during installation. Avoid using excessive force, as this can distort the seal and lead to failure.

4. Regular Inspection Periodically inspecting the oil seals for signs of wear or damage can help in proactively addressing potential issues. Look for signs such as oil leaks, which may indicate that a replacement is required.

Conclusion

In summary, cassette oil seals are indispensable components in the world of machinery and automotive engineering. Their ability to prevent leaks and block contaminants contributes significantly to the performance and longevity of equipment. By understanding the importance of these seals, how to install them correctly, and how to maintain them, operators can ensure the efficiency and reliability of their machinery. Proper attention to cassette oil seals not only safeguards the internal workings of mechanical systems but also promotes a culture of maintenance that can yield long-term benefits in terms of performance and cost savings. The value of these simple yet effective components should not be underestimated in any operational setting, making them a foundational element in the realm of machinery maintenance and engineering.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories