Dec . 12, 2024 23:34 Back to list

Wiper Rod Seal Maintenance and Replacement Tips for Optimal Performance

Understanding Wiper Rod Seals Functions and Importance

Wiper rod seals are essential components within various hydraulic and pneumatic systems, particularly in hydraulic cylinders. These seals are designed to protect the internal components from contaminants like dirt, dust, and moisture while also retaining the hydraulic fluid necessary for the optimal functioning of the system. This article explores the critical functions of wiper rod seals, their construction, maintenance considerations, and the consequences of neglecting them.

Functions of Wiper Rod Seals

The primary function of a wiper rod seal is to act as a barrier that prevents contaminants from entering the cylinder. When hydraulic systems operate, the rod moves in and out of the cylinder, which creates a path for external particles to infiltrate the system. These contaminants can lead to premature wear, decreased performance, and even catastrophic failure of the entire hydraulic unit.

In addition to keeping contaminants at bay, wiper seals also help maintain the necessary pressure within a hydraulic system. They work in tandem with other sealing components such as rod seals and end caps to ensure that the fluid remains contained within the cylinder, providing efficient power transfer and consistent performance. By retaining the hydraulic fluid, wiper rod seals contribute to the overall efficiency and longevity of the machinery.

Construction of Wiper Rod Seals

Wiper rod seals are typically made from durable materials such as polyurethane, rubber, or copolymers, chosen for their chemical resistance, flexibility, and performance at varying temperatures. The design of these seals can vary significantly depending on the specific application and operational environment.

Many wiper seals have a dual-lip configuration the primary lip contacts the rod to scrape off any debris, while the secondary lip helps keep moisture at bay. This design ensures that even if external contaminants begin to enter, they can be caught and expelled before they reach the more sensitive internal components of the hydraulic system.

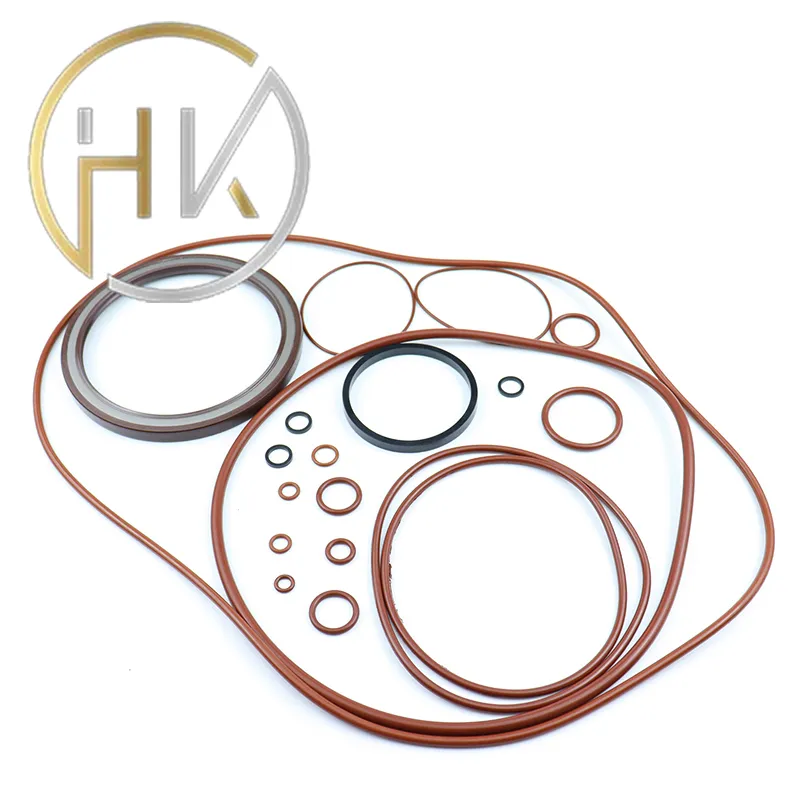

wiper rod seal

Maintenance Considerations

Proper maintenance of wiper rod seals is crucial to ensure the longevity and functionality of hydraulic systems. Regular inspection of the seals for signs of wear, cracks, or damage can prevent potential breakdowns. Lubricating the seals can help minimize friction and wear, allowing for smoother operation.

Environmental factors also play a significant role in the lifespan of wiper seals. Systems operating in harsh conditions, such as extreme temperatures or high levels of dust, require more frequent inspections and possibly the use of specialized seals engineered for those conditions.

Consequences of Neglect

Neglecting the maintenance of wiper rod seals can lead to serious consequences. Over time, worn or damaged seals can allow contaminants to penetrate the hydraulic system, causing increased wear on internal components. This can lead to hydraulic fluid leaks, decreased efficiency, and ultimately failure of the hydraulic cylinder.

Moreover, the cost of repairing or replacing a damaged hydraulic system far exceeds the cost of regularly inspecting and maintaining wiper rod seals. Therefore, investing time and resources into the upkeep of these components is both cost-effective and essential for reliable machinery operation.

Conclusion

In summary, wiper rod seals play an indispensable role in the functionality and longevity of hydraulic systems. They protect against contaminants, help maintain internal pressure, and enhance overall efficiency. Understanding their importance, ensuring regular inspections, and conducting proper maintenance can significantly improve the performance and durability of hydraulic machinery, ultimately leading to safer and more efficient operations.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories