Dec . 11, 2024 12:33 Back to list

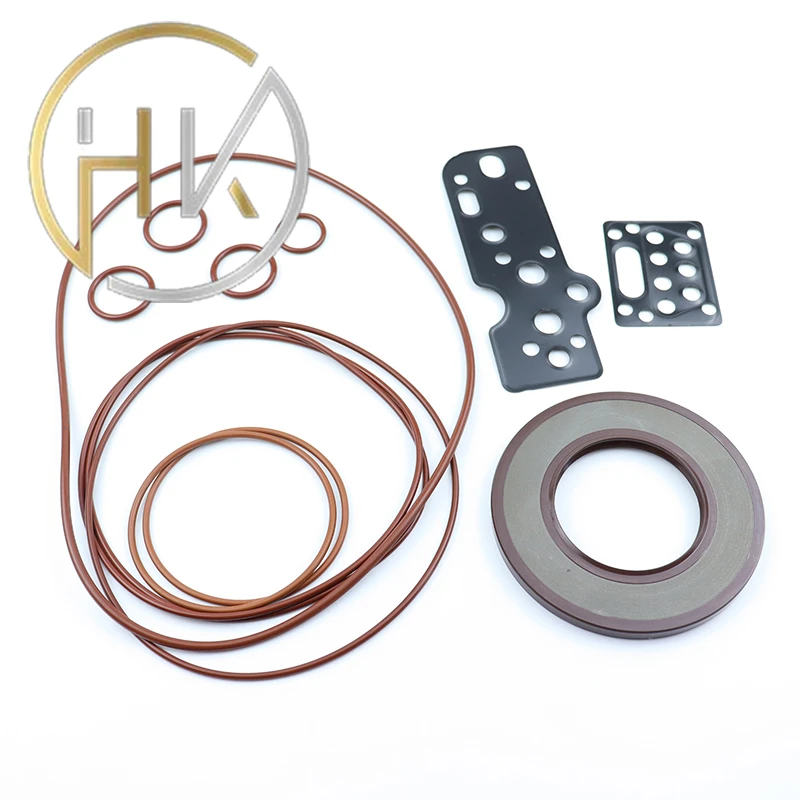

seal kit pump

The Seal Kit Pump Essential Component for Efficiency and Reliability

Pumps are crucial components in a variety of industries, from manufacturing and mining to food processing and wastewater treatment. Among the many types of pumps utilized in these sectors, the seal kit pump stands out for its significance in ensuring smooth operations. This article delves into the mechanics, importance, and maintenance of seal kit pumps.

Understanding Seal Kit Pumps

A seal kit pump is a type of pump that incorporates a seal kit designed to prevent leakage of fluids, maintain pressure, and ensure the integrity of the operating environment. The seal kit typically includes various sealing components such as O-rings, gaskets, and mechanical seals that are customized according to the pump's specifications. These components work together to create a barrier that prevents fluid from escaping, which is essential for maintaining pressure and overall efficiency.

Importance of Seal Kits

1. Leak Prevention One of the primary functions of a seal kit is to prevent leaks. Fluid leakage can lead to various issues, including loss of product, contamination of the surrounding environment, and potential safety hazards. By utilizing a reliable seal kit, companies can avoid costly downtime and the associated environmental risks.

2. Operational Efficiency Pumps that employ high-quality seal kits operate more efficiently. With effective sealing, pumps can maintain their intended pressure levels without unnecessary strain. This not only extends the lifespan of the pump but also conserves energy, leading to cost savings over time.

3. Durability and Longevity Seal kits are designed to withstand various operational stresses, including temperature fluctuations, pressure changes, and exposure to aggressive chemicals. A well-constructed seal kit ensures that the pump can operate effectively under different conditions, thereby increasing its durability and longevity.

4. Safety In many industries, the fluids being pumped can be hazardous. A seal kit plays a critical role in safeguarding the working environment by preventing leaks that could pose risks to operators and the surrounding community. Moreover, maintaining proper seals can prevent the release of harmful substances into the atmosphere.

seal kit pump

Maintenance of Seal Kits

To ensure optimal performance, regular maintenance of seal kits is essential. Here are some best practices

1. Regular Inspections Regular visual inspections of the pump and seal kit can help identify any signs of wear or damage. Cracked seals, visibly worn O-rings, or fluid stains are indicators that maintenance is required.

2. Replacement of Worn Components Over time, the sealing components may degrade due to wear and tear. It's crucial to replace any worn or damaged parts promptly to avoid leaks and maintain effective operation.

3. Flush and Clean The pump and its components should be flushed and cleaned regularly to prevent the buildup of debris, which can compromise the integrity of the seals.

4. Adhere to Manufacturer Guidelines Every pump comes with specific maintenance requirements outlined by the manufacturer. Adhering to these guidelines ensures that the pump operates at its best and that the seal kit remains intact.

5. Use Quality Replacement Parts When replacing components of the seal kit, it’s vital to use high-quality parts that meet the original specifications. Substandard materials can lead to premature failures and inefficiencies.

Conclusion

Seal kit pumps are indispensable in ensuring reliable and efficient operations across various industries. Their ability to prevent leaks, enhance operational efficiency, and ensure safety makes them a critical component of modern pumping solutions. Regular maintenance and adhering to quality standards can prolong the life of both the pump and the seal kit, leading to improved performance and reduced operational costs. In an ever-evolving industrial landscape, the seal kit pump remains a cornerstone of reliability and operational excellence.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories