Feb . 13, 2025 14:49 Back to list

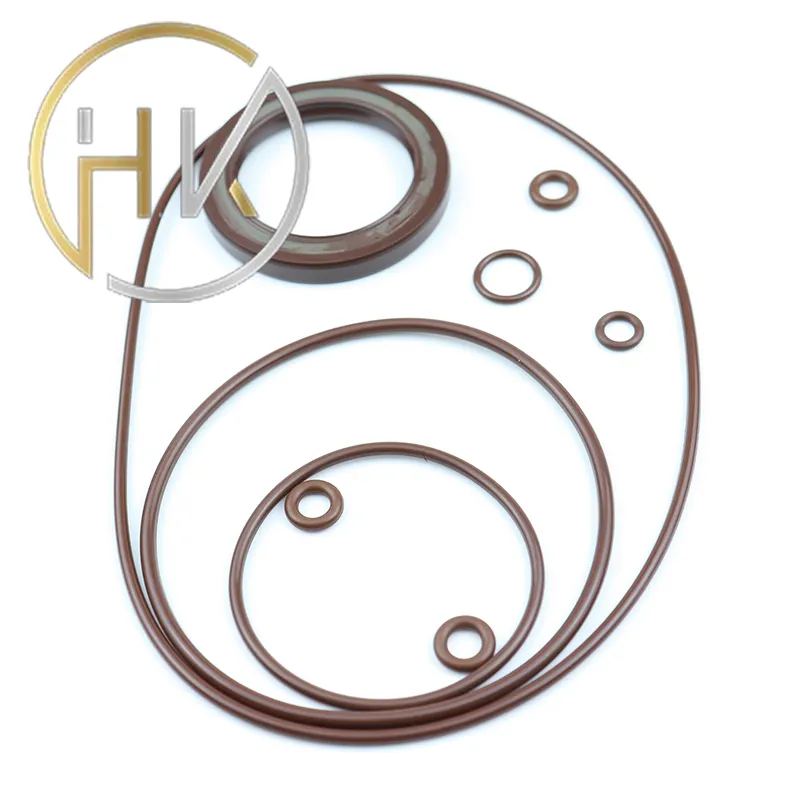

cfw oil seal

Innovation within radial oil seal technology is another area gaining attention. Advanced coatings and textures are being developed to reduce friction and wear inside the seal, which can further prolong the operational life and efficiency of the machinery. These innovations are results of extensive research and collaboration with industry leaders, aiming to push the boundaries of reliability and performance. Authority in the radial oil seal industry often comes from trusted brands with a track record of producing high-quality products. Brands like SKF, National Oil Seals, and Timken have established reputations due to their commitment to quality, ongoing research and development, and comprehensive support services. Partnering with reputable suppliers ensures access to reliable products and expert guidance, which can make a significant difference in managing and maintaining mechanical systems. Trust in radial oil seals doesn't just derive from high-quality products, but also from the assurances provided by proper certifications and standards compliance. Look for seals that meet industry standards such as ISO and DIN, which indicate that the product has undergone rigorous testing to meet performance expectations. Finally, for businesses seeking to enhance their SEO strategy around radial oil seals, content should emphasize firsthand experiences, professional expertise, and the credibility of the information shared. Descriptive, well-researched articles and customer testimonials can significantly enhance trust and engagement with your audience, drawing attention to the robust and reliable nature of your offerings. Radial oil seals, when chosen and applied correctly, are instrumental in sustaining machinery efficiency. By understanding the nuances of material choices, design configurations, installation procedures, and leveraging innovations in the field, businesses can optimize their operations and ensure the reliable performance of their machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories