Dec . 20, 2024 02:58 Back to list

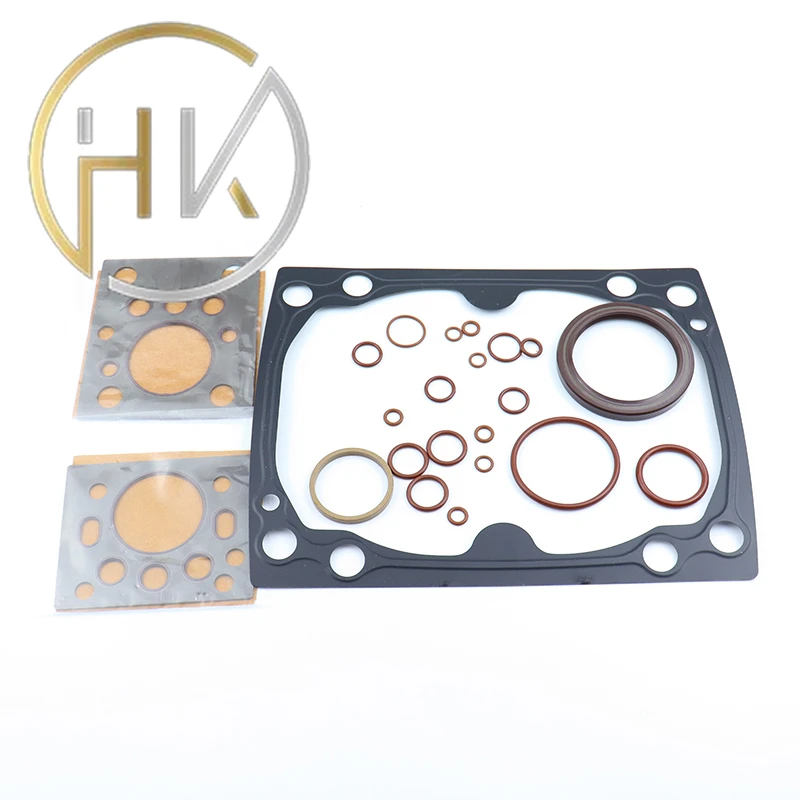

Hydraulic Cylinder Seals and Wipers for Enhanced Performance and Longevity

Understanding Hydraulic Cylinder Seals and Wipers

Hydraulic systems are crucial to a myriad of applications across various industries, from construction machinery to aerospace operations. One of the critical components within these systems is the hydraulic cylinder, which converts hydraulic energy into mechanical force. To ensure the efficient operation of hydraulic cylinders, the use of seals and wipers is essential. This article delves into the importance, types, and best practices for hydraulic cylinder seals and wipers.

The Role of Seals in Hydraulic Cylinders

Hydraulic cylinder seals are designed to prevent fluid leaks from the cylinder while also ensuring that external contaminants do not enter the hydraulic system. This dual functionality is vital for maintaining the performance and longevity of the hydraulic cylinder. There are several types of seals used in hydraulic applications, including

1. Rod Seals These seals are located at the cylinder head and prevent hydraulic fluid from leaking out when the rod is extending or retracting. They are crucial to maintaining pressure within the cylinder. 2. Piston Seals Found on the piston within the cylinder, these seals ensure that hydraulic fluid can effectively transmit force from the cylinder to the rod. A well-functioning piston seal is essential for the efficient transfer of energy.

3. Buffer Seals These are often used in combination with piston seals to absorb and mitigate pressure surges that could lead to seal failure. Buffer seals provide an extra line of defense against leakage.

4. Guide Rings While not seals in the traditional sense, guide rings support the rod and piston by reducing friction and wear, thus extending the life of the seals.

The materials used for these seals are diverse and chosen based on the environment and fluid compatibility. Common materials include polyurethane, nitrile, and fluorocarbon, each providing a balance between durability and flexibility.

The Importance of Wipers

The role of wipers in hydraulic systems is equally important as they serve to keep sliding surfaces clean and free from debris, which could lead to seal damage or failure. Wipers are typically fitted on the cylinder head and work in conjunction with rod seals by scraping off any dirt or contaminants that could enter the cylinder.

Types of Wipers 1. Static Wipers These remain stationary while the rod moves. They thoroughly clean the rod as it retracts into the cylinder. 2. Dynamic Wipers Unlike static wipers, dynamic wipers may move with the rod, providing continuous cleaning action alongside the movement.

hydraulic cylinder seals and wipers

Wipers play a significant role in maintaining the integrity of hydraulic seals by preventing abrasive particles from causing wear and tear. This is crucial because even minor contamination can lead to significant operational issues over time.

Best Practices for Maintenance and Longevity

To ensure optimal performance of hydraulic cylinder seals and wipers, regular maintenance is vital. Here are some best practices

1. Routine Inspections Regularly check seals and wipers for signs of wear, such as cuts, abrasions, or discoloration. Early detection of wear can prevent costly failures.

2. Cleaning Keep the area around the hydraulic cylinder clean. Dirt and debris can compromise the seals and wipers, leading to premature failure.

3. Fluid Quality Use the appropriate hydraulic fluid as specified by the manufacturer. Contaminated or incorrect fluids can degrade seals and wipers.

4. Proper Installation During installation, ensure that seals and wipers are fitted correctly. Improper installation can lead to immediate failures or reduce their operational lifespan.

5. Monitor Operating Conditions Be aware of the temperature and pressure conditions the hydraulic system operates under. High temperatures can accelerate wear on seals, while excessive pressure can lead to seal failure.

Conclusion

In conclusion, hydraulic cylinder seals and wipers are indispensable components that ensure the efficiency and reliability of hydraulic systems. By understanding their roles and adhering to best maintenance practices, industry professionals can extend the life of hydraulic equipment and avoid unexpected downtime. In an era where efficiency is paramount, paying attention to these small but vital components can yield significant benefits in both performance and cost-effectiveness.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories