Jan . 23, 2025 05:12 Back to list

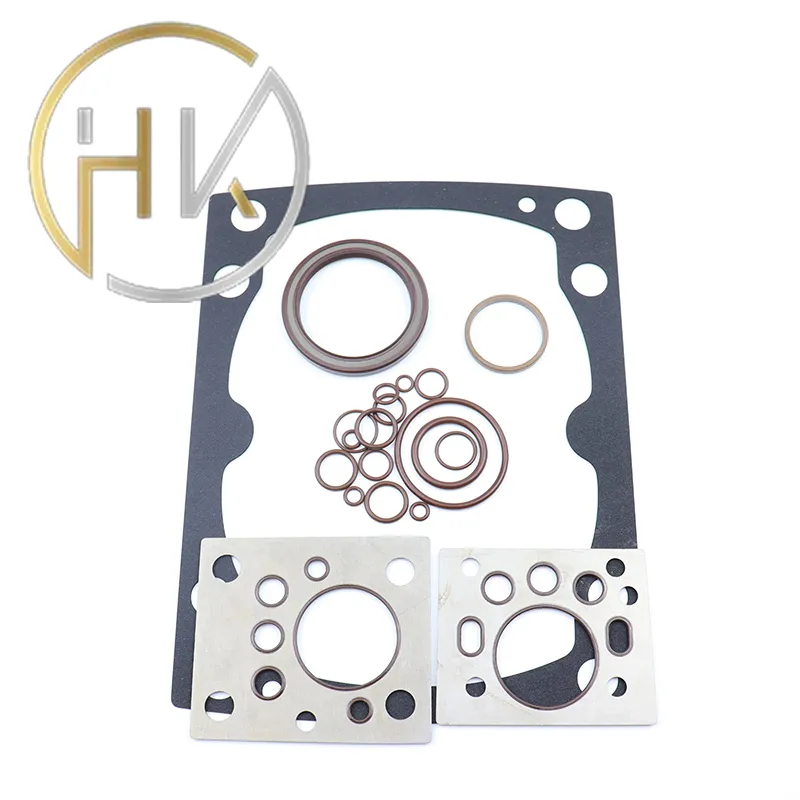

45-63-8 TCV oil seal High pressure oil seal

Over time, seals within hydraulic systems wear out due to the nature of their operation. A proactive approach involving the regular use of rebuild kits can mitigate such wear. However, knowing when to utilize a rebuild kit is vital. Indicators include reduced performance, visible leaks, or changes in pressure levels. Addressing these issues promptly with the appropriate rebuild kit can prevent minor issues from escalating into major repairs. Furthermore, the environmental impact of machinery maintenance is a growing concern. By opting for rebuild kits instead of new cylinder replacements, businesses can significantly reduce waste. This sustainable approach not only supports environmental goals but also aligns with corporate responsibility standards, which can enhance a business's reputation among eco-conscious consumers and partners. The cost-effectiveness of hydraulic cylinder rebuild kits is another aspect that appeals to businesses looking to optimize operational costs. While the initial purchase price is essential, the long-term savings from avoiding downtime and extending equipment life far outweigh the upfront investment. In summary, hydraulic cylinder rebuild kits offer a reliable, cost-effective, and sustainable solution for maintaining hydraulic systems. Their proper use, guided by expertise in hydraulic mechanics, can significantly reduce maintenance costs and extend the longevity of machinery across various industries. When sourced from reputable suppliers and installed with precision, these kits help maintain efficient and smooth operation, ensuring that business operations run without interruption.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories