Dec . 12, 2024 13:24 Back to list

oil seal for rotating shaft

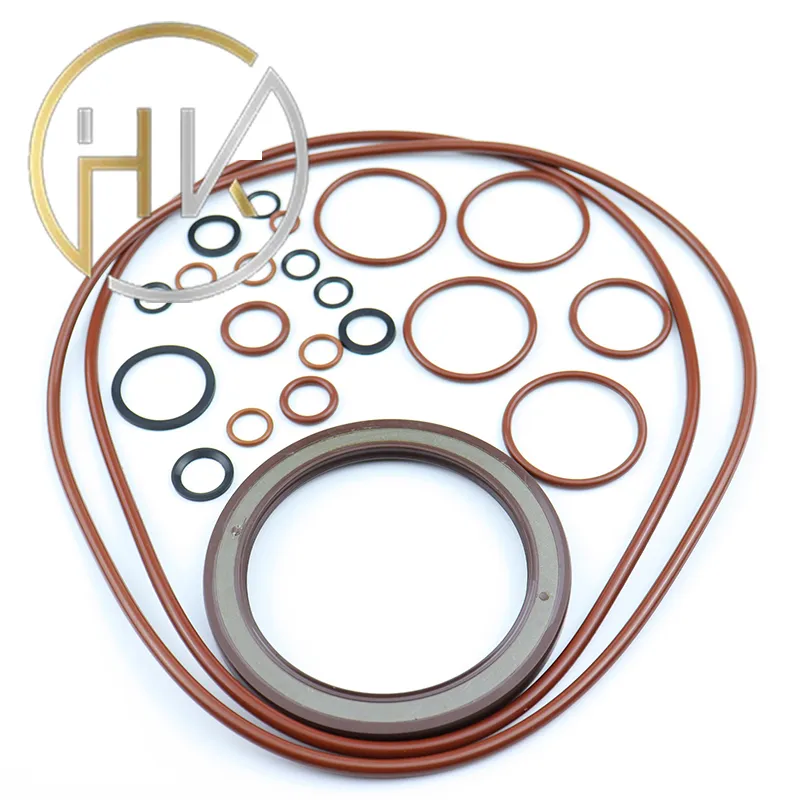

Understanding Oil Seals for Rotating Shafts

Oil seals, also known as radial oil seals or shaft seals, are critical components used in various mechanical systems. Their primary function is to prevent leakage of lubricants, such as oil, while also protecting internal components from dirt, dust, and moisture. This article delves into the significance, design, and application of oil seals for rotating shafts, emphasizing their role in enhancing the performance and longevity of machinery.

Importance of Oil Seals

In rotating machinery, such as motors, gearboxes, and pumps, oil serves as a lubricant to reduce friction between moving parts, thereby minimizing wear and tear. However, without proper sealing mechanisms, the lubricant can easily escape, leading to decreased efficiency, overheating, and eventual failure of the machinery. Oil seals are designed to confine the lubricant within the system and protect it from external contaminants. Their effectiveness directly influences the operational reliability and maintenance requirements of mechanical systems.

Design and Construction

Oil seals typically consist of several key components a sealing lip, a casing, and a spring (in some designs).

1. Sealing Lip The sealing lip is the most critical part of the oil seal. It makes contact with the rotating shaft, creating a barrier to prevent fluid leakage. The lip is generally made of elastomeric materials, which are chosen for their resilience, temperature resistance, and compatibility with the lubricant being used. Common materials include Nitrile Rubber (NBR), Fluoroelastomer (FKM), and silicone rubber, each selected based on the specific operating conditions.

2. Casing The casing of the oil seal is designed to fit securely within a housing or bore. It is typically made of rigid materials, such as metal or rigid plastic, ensuring a stable structure that houses the sealing lip.

3. Spring Some oil seals incorporate a small spring around the lip to maintain consistent contact with the shaft, compensating for any wear or deformation that might occur over time. This feature enhances the seal's effectiveness, particularly in high-speed applications.

oil seal for rotating shaft

Application of Oil Seals

Oil seals are utilized across a plethora of industries and applications. Some common uses include

- Automotive Oil seals are prevalent in engines, transmissions, and differentials. They prevent oil leaks that could lead to mechanical failures and ensure that lubricants are maintained at optimal levels.

- Industrial Machinery In factories, oil seals are found in gearboxes, pumps, and hydraulic systems, playing a vital role in ensuring efficient operation and reducing maintenance downtime.

- Aerospace High-performance oil seals are crucial in aerospace applications, where they must withstand extreme temperatures and pressures while maintaining sealing integrity.

- Household Appliances Oil seals are also found in washing machines, refrigerators, and other appliances, preventing leaks and protecting internal components.

Maintenance and Selection

Choosing the correct oil seal for a specific application is paramount to achieving optimal performance. Factors such as operating temperature, pressure, shaft speed, and the type of lubricant should be considered. Regular maintenance checks can also help in detecting wear and tear of oil seals, enabling timely replacements and minimizing the risk of machinery breakdown.

In summary, oil seals for rotating shafts are essential components that safeguard machinery from lubricant leaks and contaminants. By understanding their design, application, and maintenance requirements, engineers and technicians can ensure the efficiency and longevity of mechanical systems. The right selection and upkeep of oil seals not only enhance operational performance but also contribute to reduced maintenance costs and improved reliability in various applications. Whether in automotive, industrial, or household settings, the significance of oil seals cannot be overstated as they play a pivotal role in the smooth running of rotating machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories