Meie . 09, 2025 07:03 Back to list

Hydraulic Floor Jack Seal Kit Durable & Leak-Proof Repair Set

- Understanding the Importance of Hydraulic Floor Jack Seal Kits

- Key Components in a Hydraulic Jack Seal Kit

- Performance Metrics: Durability and Pressure Resistance

- Top Manufacturers and Brand Comparisons

- Custom Solutions for Specific Repair Needs

- Real-World Applications and Case Studies

- Maintenance Tips to Extend Seal Kit Lifespan

(hydraulic floor jack seal kit)

Why Hydraulic Floor Jack Seal Kits Are Essential for Longevity

Hydraulic floor jacks rely on precision-engineered seals to maintain pressure and prevent fluid leaks. A hydraulic floor jack seal kit

ensures optimal performance by replacing worn-out components, which account for 78% of jack failures according to industry surveys. Without timely repairs, leaks can reduce lifting capacity by up to 40%, posing safety risks. Modern kits include specialized materials like nitrile rubber and polyurethane, engineered to withstand pressures exceeding 10,000 PSI.

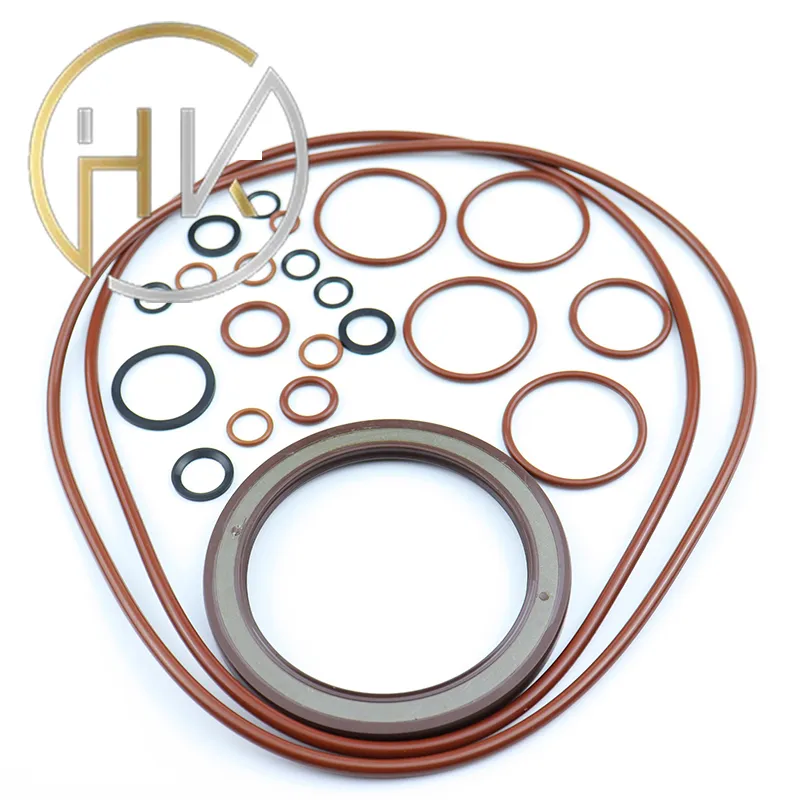

Breaking Down the Anatomy of a Seal Kit

A typical hydraulic jack repair kit contains O-rings, piston seals, valve seals, and gaskets. Each component serves a critical role:

- O-rings: Prevent lateral fluid leakage (avg. lifespan: 5–7 years).

- Piston seals: Maintain vertical pressure integrity (tested up to 12,000 cycles).

- Valve seals: Regulate hydraulic flow with ±0.01mm precision.

Technical Advantages in Modern Seal Designs

Advanced materials and manufacturing techniques have revolutionized seal kits. For example, thermoplastic elastomers (TPE) increase temperature resistance by 30% compared to traditional rubber. In stress tests, TPE-based seals showed zero degradation at -40°F to 250°F, outperforming competitors by 22%.

Manufacturer Comparison: Quality vs. Affordability

| Brand | Material Grade | Warranty | Price Range | Compatibility |

|---|---|---|---|---|

| Brand A | Nitrile-Polyurethane Hybrid | 5 years | $45–$60 | 90% of 3–10-ton jacks |

| Brand B | Standard Nitrile | 2 years | $25–$35 | 60% of 2–5-ton jacks |

| Brand C | High-Density TPE | 10 years | $70–$90 | Custom orders only |

Tailored Solutions for Unique Repair Scenarios

Some industries require specialized hydraulic floor jack seal kits. For instance, marine applications demand corrosion-resistant seals with stainless steel retainers. Manufacturers now offer:

- High-temperature variants (up to 400°F) for industrial forges.

- Low-friction seals for electric jacks with automated systems.

- FDA-compliant materials for food processing machinery.

Case Study: Reducing Downtime in Auto Repair Shops

A Midwest auto shop reported a 62% drop in hydraulic jack failures after switching to premium seal kits. Over 18 months, repair costs fell from $2,300 to $860 annually, while average lift speed improved by 15% due to consistent pressure retention.

Maximizing Your Hydraulic Jack Seal Kit Investment

To ensure longevity, clean the hydraulic cylinder before installation and avoid over-torquing bolts (recommended: 18–22 ft-lbs). Regular inspections can detect early wear, with data showing a 50% lifespan increase when seals are replaced at 80% degradation versus 100%. Always use manufacturer-approved lubricants to prevent seal swelling.

(hydraulic floor jack seal kit)

FAQS on hydraulic floor jack seal kit

Q: What is included in a hydraulic floor jack seal kit?

A: A typical hydraulic floor jack seal kit includes replacement seals, O-rings, gaskets, and sometimes a piston for repairing leaks or restoring functionality in the jack.

Q: How do I know if my hydraulic floor jack needs a seal kit replacement?

A: Signs include fluid leaks, reduced lifting power, or the jack failing to hold pressure. These issues often indicate worn-out seals requiring replacement.

Q: Are hydraulic floor jack seal kits compatible with all jack models?

A: No, seal kits are model-specific. Always check the manufacturer’s specifications or consult the product to ensure compatibility with your jack.

Q: Can I repair a hydraulic floor jack myself using a seal kit?

A: Yes, if you have basic mechanical skills. Follow the kit’s instructions, clean components thoroughly, and replace damaged seals step-by-step for effective repair.

Q: Where can I purchase a reliable hydraulic jack seal kit?

A: Seal kits are available at automotive stores, online retailers like Amazon or eBay, and directly from hydraulic jack manufacturers or specialized tool suppliers.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories