Jan . 23, 2025 01:50 Back to list

wiper seal types

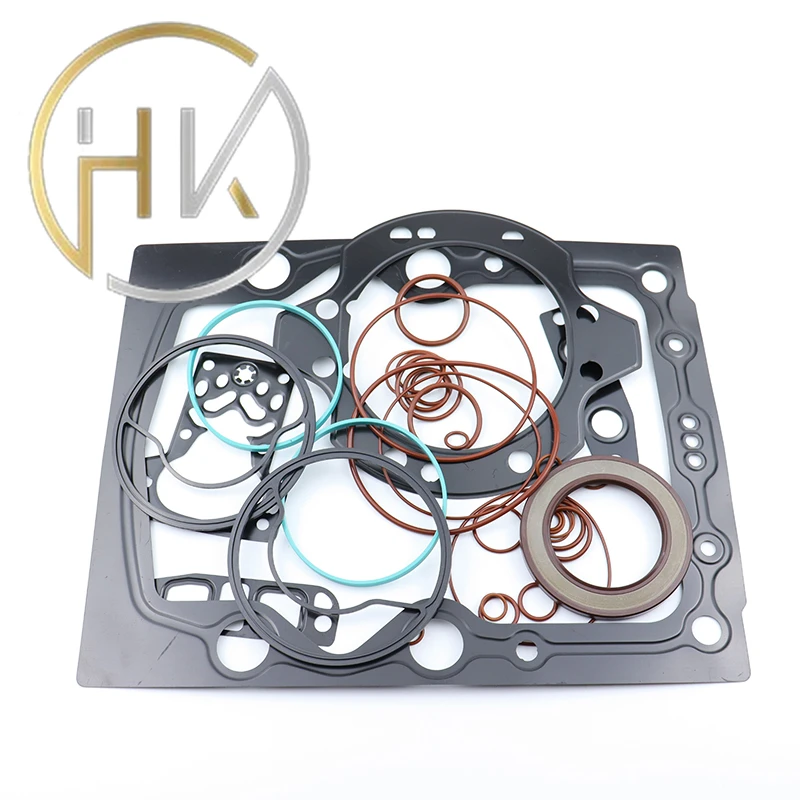

Known for their abrasion resistance and resilience, polyurethane wiper seals offer an excellent alternative for high-wear applications. These seals can withstand harsh chemical environments and remain flexible over a wide temperature range. With these attributes, polyurethane wiper seals are a favorite in heavy machinery, earth-moving equipment, and other applications demanding durability and long-term performance. 4. Spring-Loaded Wiper Seals For applications requiring consistent contact pressure between the seal and the rod, spring-loaded wiper seals offer an innovative solution. These seals incorporate a helically wound spring to maintain uniform pressure on the wiping lip, enhancing the seal's ability to handle variations in rod alignment or movement. This design is particularly effective in precision tools and equipment where exact functionality is paramount. 5. Double-Lip Wiper Seals Double-lip wiper seals provide an extra layer of protection by incorporating two sealing edges. The primary lip ensures contaminants are effectively wiped away, while the secondary lip acts as an additional barrier, minimizing the risk of ingress even further. This configuration is beneficial in environments with high contamination levels, such as agriculture and construction industries. Choosing the right wiper seal is crucial for optimizing machinery performance and ensuring longevity. Material composition, environmental conditions, and the specific nature of the application must all be considered when selecting a wiper seal. Investing in quality seals from reputable manufacturers can prevent downtime and reduce maintenance costs, reinforcing the importance of informed decision-making in this area. In conclusion, understanding the different types of wiper seals and their unique attributes allows businesses to enhance operational efficiency and improve overall equipment reliability. Whether dealing with standard industrial applications or demanding heavy-duty environments, the right wiper seal can make a significant difference in performance and longevity. By considering factors such as material compatibility, environmental conditions, and mechanical requirements, companies can ensure they are making informed choices, backed by experience, expertise, and trust in high-quality sealing solutions.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories