Déc . 19, 2024 02:13 Back to list

white hydraulic motor seal kit

Understanding White Hydraulic Motor Seal Kits

Hydraulic systems are a cornerstone of modern machinery, providing the power and efficiency required in various industrial and construction applications. A critical component of these systems is the hydraulic motor, which translates hydraulic energy into mechanical power. However, to ensure optimal performance and longevity of a hydraulic motor, the integrity of its seals is paramount. This is where seal kits, such as the White hydraulic motor seal kit, come into play.

The Importance of Hydraulic Motor Seals

Hydraulic motors operate under high pressure, and the seals within these motors are responsible for maintaining this pressure while preventing fluid leaks. Over time, exposure to heat, pressure, and various hydraulic fluids can lead to wear and tear, resulting in leaks and reduced efficiency. When seals begin to fail, the performance of the hydraulic motor can deteriorate, leading to costly downtime and repairs. Therefore, maintaining the integrity of hydraulic motor seals through regular inspections and replacements is essential.

What is a White Hydraulic Motor Seal Kit?

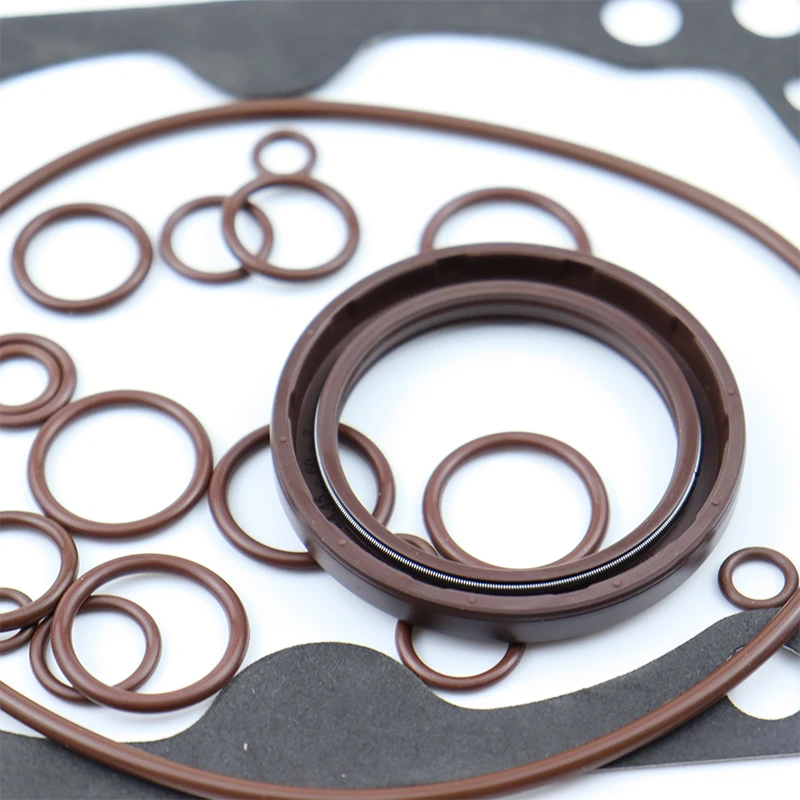

A White hydraulic motor seal kit is a comprehensive package containing all the necessary seals and related components required to service or rebuild a hydraulic motor from White, a reputable manufacturer known for its durable and efficient hydraulic solutions. These kits typically include various types of seals, such as O-rings, shaft seals, and backup rings, along with installation instructions. By utilizing a seal kit specifically designed for White motors, users can ensure compatibility and reliable performance.

Key Components of the Seal Kit

1. O-Rings These are circular seals made from rubber or synthetic materials that fit into grooves on the motor. They form a tight seal between components, preventing fluid leakage while allowing for some movement.

2. Shaft Seals Also known as lip seals, these components are placed around the shaft of the motor to prevent hydraulic fluid from leaking out while keeping contaminants out. They are designed to withstand high pressures and temperatures, making them crucial for motor longevity.

white hydraulic motor seal kit

3. Backup Rings These are used in conjunction with O-rings to prevent extrusion in high-pressure situations. They provide additional support and help maintain the integrity of the seal under demanding conditions.

4. Installation Hardware Some kits may also include necessary hardware such as clamps, screws, or spacers required for installation, ensuring users have everything they need for a complete repair.

Benefits of Using Seal Kits

One of the major advantages of using a seal kit, particularly the White hydraulic motor seal kit, is the assurance of quality and compatibility. These kits are specifically designed for particular models of hydraulic motors, ensuring a perfect fit and proper function. Additionally, purchasing a kit can be more cost-effective than buying individual seals separately. It simplifies the repair process by providing all components in one package, reducing the risk of overlooking necessary parts.

When to Replace Seals

Regular maintenance checks are essential for hydraulic systems. Look for signs of leaking fluid, a drop in performance, or unusual noises from the motor, which may indicate seal failure. If any of these symptoms are present, it may be time to consider replacing the seals. Following the manufacturer’s guidelines for service intervals is also a good practice to ensure the longevity of the hydraulic motor.

Conclusion

The White hydraulic motor seal kit is an essential resource for anyone operating hydraulic systems, especially those utilizing White products. Regular maintenance and timely replacement of seals can prevent operational issues, minimize downtime, and enhance the overall life of the hydraulic motor. By investing in a quality seal kit, users can ensure their hydraulic machinery operates at peak performance, enabling them to meet the demands of their work with confidence. Whether you are in construction, manufacturing, or any industry reliant on hydraulic systems, understanding the importance of seal maintenance is crucial to achieving operational excellence.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories