Fév . 16, 2025 07:09 Back to list

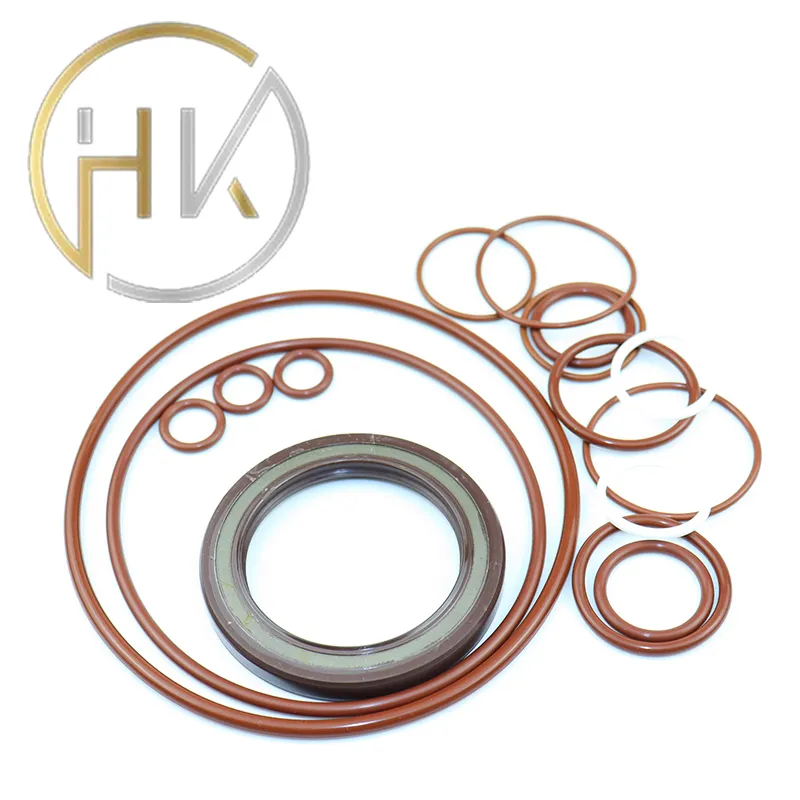

hydraulic floor jack repair kit

Early mastery of these skills not only enhances your repair proficiency but also ensures the longevity of the jack. After replacing the damaged components, reassemble the jack carefully and fill it with hydraulic fluid, being mindful not to overfill. Testing the jack post-repair is a crucial step. Gradually test its lifting ability under a controlled load to confirm that it can sustain the weight without any hitches. Any discrepancies during this testing phase might indicate an oversight that necessitates a quick revisit of the repair process. The professional knowledge and trustworthiness reinforced by using high-quality, manufacturer-recommended hydraulic floor jack repair kits are invaluable. Opting for such validated kits means that the materials used in repairs are up to industry standards, thereby enhancing the tool's reliability post-repair. Additionally, regularly inspecting and maintaining the jack, even after successful repairs, prevents premature wear and ensures safety. Investing in a repair kit not only augments your toolbox but also provides educational insight into the mechanical workings of a hydraulic system. Whether you're a seasoned mechanic doing preventive maintenance or a DIY enthusiast keen on extending the lifespan of your tools, understanding when and how to employ a repair kit extremely influences your repair outcomes. Ultimately, arming yourself with the right repair kit and knowledge can greatly mitigate downtime and repair costs associated with hydraulic floor jack failures. Continuous learning and application of best repair practices solidify your role as a trusted and competent authority in automotive tool maintenance and underscore your commitment to quality, safety, and efficiency.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories