Nov . 09, 2024 23:36 Back to list

Understanding Cylinder Gland Seals and Their Importance in Hydraulic Systems

Understanding Cylinder Gland Seals Importance, Design, and Applications

In the world of fluid power systems, cylinder gland seals play a crucial role in ensuring the efficiency, reliability, and longevity of hydraulic and pneumatic cylinders. These seals are essential components that prevent fluid leakage while allowing the movement of the piston within the cylinder. This article delves into the importance, design considerations, and applications of cylinder gland seals.

Importance of Cylinder Gland Seals

Cylinder gland seals are vital in maintaining pressure within hydraulic and pneumatic cylinders. Their primary function is to prevent the escape of hydraulic fluid or air from the cylinder while simultaneously blocking contaminants from entering. A failure in the gland seal can lead to significant operational issues, including reduced system efficiency, increased wear on components, and potential system failures. Additionally, fluid leaks can create safety hazards and environmental concerns.

Another critical aspect of these seals is their role in ensuring effective energy usage. A well-functioning gland seal minimizes friction between the piston and cylinder walls, thereby enhancing the overall efficiency of the system. Furthermore, the operating temperature and pressure of the cylinder can significantly impact seal performance, making it essential to select the right type of seal material and design.

Design Considerations

The design of cylinder gland seals involves various considerations, including material selection, geometry, and operational parameters

.1. Material Selection The choice of material is paramount in determining the seal’s performance. Common materials used for gland seals include elastomers, thermoplastics, and composites. Each material has its advantages and drawbacks related to temperature resistance, chemical compatibility, and wear resistance. For instance, nitrile rubber is widely used for its good abrasion resistance and flexibility, while fluorocarbon materials are favored for their excellent chemical resistance.

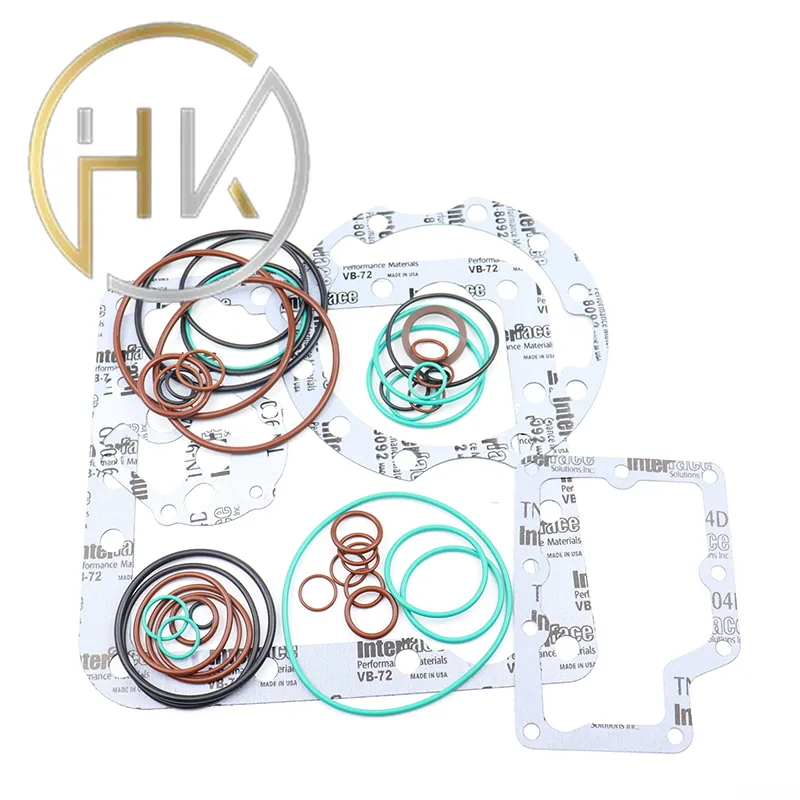

cylinder gland seal

2. Seal Geometry The shape and configuration of the seal must be tailored to meet the specific requirements of the application. Type, size, and profile of the seal can greatly influence the sealing effectiveness and the frictional characteristics. Common designs include O-rings, U-cups, and V-seals. Each design is suited for distinct types of pressures and motion patterns, and understanding the dynamics of the application is critical for selecting the optimal seal design.

3. Operating Conditions The performance of the cylinder gland seal is intrinsically linked to the operating conditions, including temperature, pressure, and the type of fluid. High-pressure applications require seals that can withstand hydraulic forces without deforming, while high-temperature applications necessitate materials that can maintain integrity under thermal stress.

4. Wear Resistance Given that cylinder gland seals are subjected to constant motion and pressure, their wear resistance is a critical design characteristic. High-quality seals can significantly reduce wear on both the seals and the mating surfaces of the cylinder, prolonging the life of the entire assembly.

Applications of Cylinder Gland Seals

Cylinder gland seals are employed across various industries and applications. In the automotive sector, they are integral to hydraulic brake systems and power steering systems. In aerospace, these seals are vital for controlling hydraulic systems in aircraft, ensuring both safety and reliability.

In industrial applications, hydraulic presses, injection molding machines, and metal forming equipment rely on effective sealing solutions to maintain their operational efficiency. Additionally, in construction machinery, such as excavators and loaders, hydraulic cylinders equipped with robust gland seals ensure the reliable performance of equipment under demanding conditions.

Conclusion

Cylinder gland seals are indispensable components in hydraulic and pneumatic systems, playing a crucial role in enhancing efficiency and safety. By understanding the significance of these seals, alongside their design and application considerations, engineers and technicians can make informed decisions that lead to enhanced performance and reduced maintenance costs. As technology advances and demands for efficiency increase, the importance of high-quality cylinder gland seals will only continue to grow, underscoring their significance in modern industrial applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories