Déc . 03, 2024 14:15 Back to list

25x38x7 oil seal

Understanding the Importance of the 25x38x7 Oil Seal

In the world of machinery and automotive engineering, oil seals play a crucial role in ensuring the efficient and reliable operation of various systems. Among the myriad of oil seals available, the 25x38x7 oil seal holds a significant position due to its versatile applications and essential functions. This article explores the characteristics, applications, and significance of the 25x38x7 oil seal in various industries.

Characteristics of the 25x38x7 Oil Seal

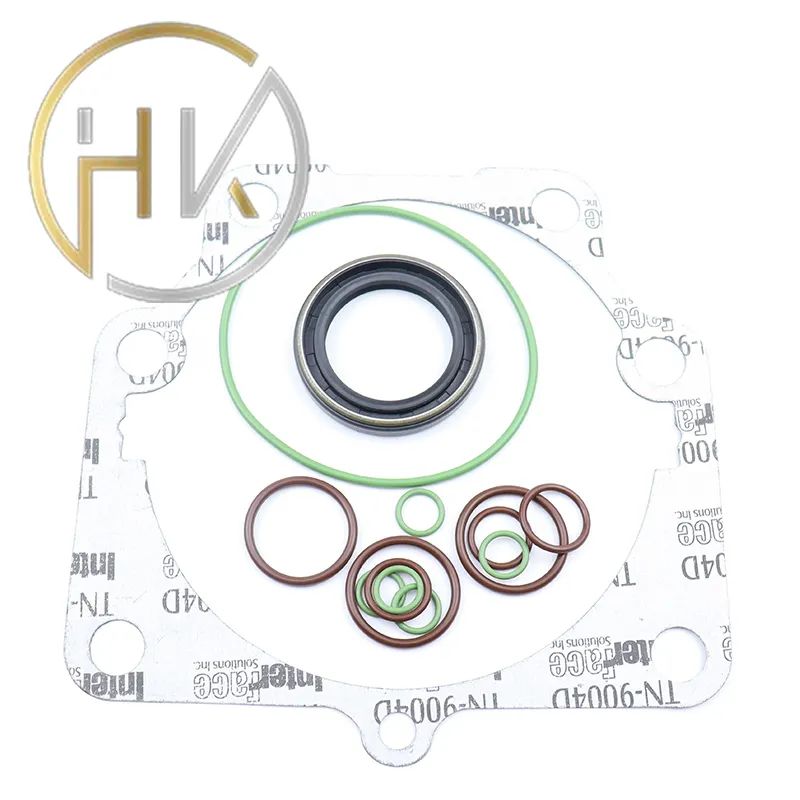

The dimensions of the 25x38x7 oil seal refer to its inner diameter (25 mm), outer diameter (38 mm), and thickness (7 mm). These specific measurements are fundamental as they determine the seal's compatibility with various shafts and housings. The precision design of the seal ensures a snug fit, preventing the leakage of fluid while allowing smooth rotational motion.

Typically made from durable materials such as rubber or synthetic compounds, the 25x38x7 oil seal is designed to withstand a range of operating conditions. Its resilient material provides excellent resistance to wear and tear, ensuring longevity and reliability. Furthermore, these seals often come with added features such as dust lips or spring-loaded designs, enhancing their effectiveness in sealing applications.

Applications of the 25x38x7 Oil Seal

The 25x38x7 oil seal is widely used across various sectors due to its adaptability. Its primary function is to retain lubricants within machinery while preventing external contaminants such as dust, water, and dirt from entering. This is particularly vital in automotive applications, including engines, gearboxes, and differential covers.

25x38x7 oil seal

In automotive engines, for instance, oil seals are essential for maintaining the integrity of the lubrication system. They prevent oil leaks that can lead to severe engine damage and performance issues. A failure in the oil sealing system could result in a significant loss of oil, leading to increased friction and heat within the engine, potentially causing catastrophic failures.

In addition to automotive applications, the 25x38x7 oil seal is extensively used in industrial machinery. Equipment such as pumps, compressors, and motors all benefit from the use of reliable oil seals. By ensuring that lubricants remain contained within the system, these seals contribute to the overall efficiency and effectiveness of industrial operations.

Significance of the 25x38x7 Oil Seal

The significance of the 25x38x7 oil seal extends beyond mere sealing capabilities. Its role in maintaining the fluid integrity of operating machinery is vital for reducing maintenance costs and prolonging equipment life. Regular maintenance and timely replacement of worn-out seals can prevent costly repairs and downtime, which is crucial for industries where machines operate on tight schedules.

Furthermore, the use of effective oil seals enhances the overall safety of machinery. By preventing leaks that could lead to spills or hazardous situations, oil seals play a critical role in maintaining a safe working environment. This aspect is especially important in industries dealing with volatile substances or operating in demanding conditions.

Conclusion

In summary, the 25x38x7 oil seal is a small yet indispensable component in numerous mechanical systems. Its ability to effectively contain lubricants while blocking contaminants ensures optimal performance and longevity of machinery. Whether in automotive applications or industrial settings, the importance of choosing the right oil seal cannot be overstated. As technology continues to advance, the design and materials used in oil seals like the 25x38x7 will evolve, providing even greater efficiency and reliability in the future. Understanding the significance of such components helps engineers and technicians to appreciate the small but vital parts that contribute to the greater functionality of machines, ultimately leading to enhanced productivity and safety in various industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories