marras . 22, 2024 11:03 Back to list

seals and wipers

Seals and Wipers Essential Components for Efficient Machinery

When we think of machines, we often focus on the engine's power, the cutting-edge technology, or the intricate designs that lead to optimal performance. However, lurking quietly in the background are the often-overlooked components that ensure these machines function seamlessly seals and wipers. These integral parts play critical roles in maintaining the longevity and efficiency of various machinery, from automotive engines to industrial equipment.

Understanding Seals

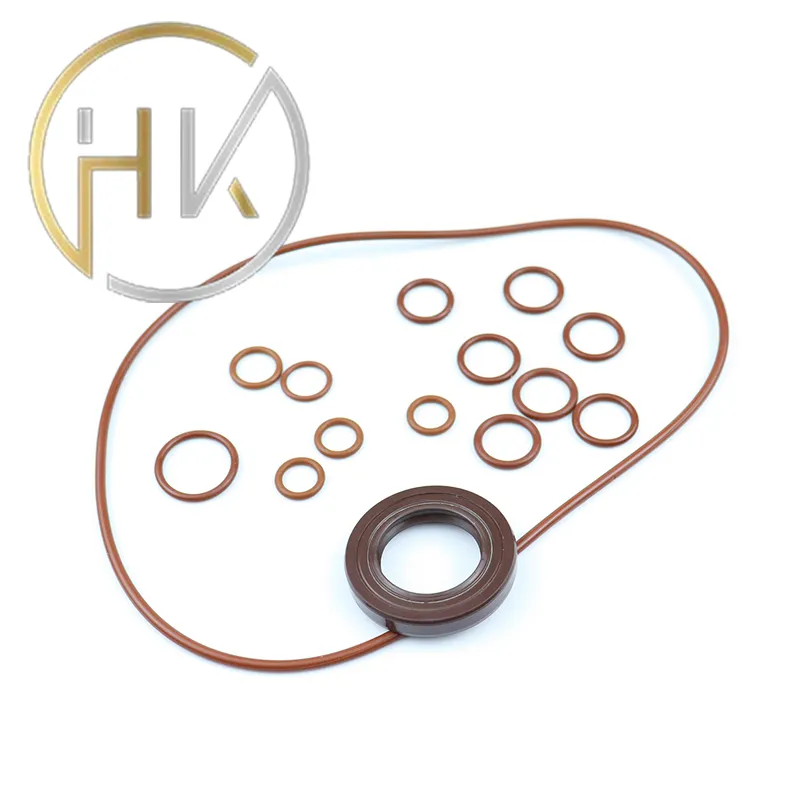

Seals are devices used to prevent the leakage of fluids or gases. In many applications, they are vital for protecting components from contaminants and ensuring that hydraulic and pneumatic systems operate effectively. There are different types of seals, each suited to specific functions. For instance, O-rings are circular seals that fit into grooves, providing a tight seal in applications like hydraulic cylinders. Lip seals, on the other hand, are designed to protect rotating shafts from dirt and moisture, crucial in mechanical systems such as engines and pumps.

The material of the seal is equally important. Depending on the application, seals can be made from elastomers, thermoplastics, or metals. Each material has distinct properties that make it suitable for particular operating conditions. For example, Viton is a popular choice for seals exposed to harsh chemicals because of its resilience and thermal stability, while polyurethane seals provide excellent wear resistance in dynamic applications.

The Role of Wipers

Wipers, sometimes referred to as scrapers or dust seals, serve a slightly different purpose. Their primary function is to prevent contaminants from entering critical areas of machinery while also removing foreign particles from exposed surfaces. This is especially crucial in any machinery that relies on precision and cleanliness, such as hydraulic systems, bearings, and linear guides.

seals and wipers

Wipers are typically made from softer materials like rubber or polyurethane. Their design is often specialized to fit certain applications, with some featuring a lip that presses against the surface to effectively scrape away debris. Proper wiper design and placement can significantly enhance the operational life of machinery by reducing wear and tear caused by dirt and other contaminants.

The Synergy Between Seals and Wipers

While seals and wipers serve different functions, they work together to ensure optimal performance and longevity of equipment. In hydraulic systems, for example, seals prevent fluid from leaking out of the cylinders while wipers keep the rod clean and free from dirt that could damage the seal. This synergy reduces the risk of failure and minimizes maintenance costs, which can be substantial in industrial settings.

Regular maintenance and inspection of seals and wipers are essential practices for any machinery owner. Over time, these components can wear out due to friction, pressure, or exposure to harsh conditions. Identifying and replacing worn seals and wipers can prevent larger mechanical failures and ensure the machinery runs efficiently.

Conclusion

In conclusion, while seals and wipers may not be the most glamorous components of machinery, their importance cannot be overstated. They are the unsung heroes that work tirelessly behind the scenes to prevent leaks, exclude contaminants, and maintain the integrity of critical systems. By understanding their functions and ensuring they are regularly maintained, operators can significantly enhance the performance and lifespan of their machinery. Whether in automotive applications or industrial settings, the thoughtful design and selection of seals and wipers are essential for achieving operational excellence. As technology continues to evolve, so too will the materials and designs used in these fundamental components, ensuring that they meet the demands of increasingly advanced machinery.

Investing in quality seals and wipers is not just a matter of maintenance; it's a commitment to reliability and efficiency.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories