marras . 20, 2024 07:14 Back to list

replacing seals on a hydraulic cylinder

Replacing Seals on a Hydraulic Cylinder

Hydraulic cylinders are critical components in various machinery, serving functions across industries such as construction, manufacturing, and automotive. However, over time, the seals within these cylinders may wear out due to continuous use or exposure to harsh conditions. Replacing seals on a hydraulic cylinder is an essential maintenance task that can improve performance and extend the lifespan of the equipment.

Understanding Hydraulic Cylinders and Seals

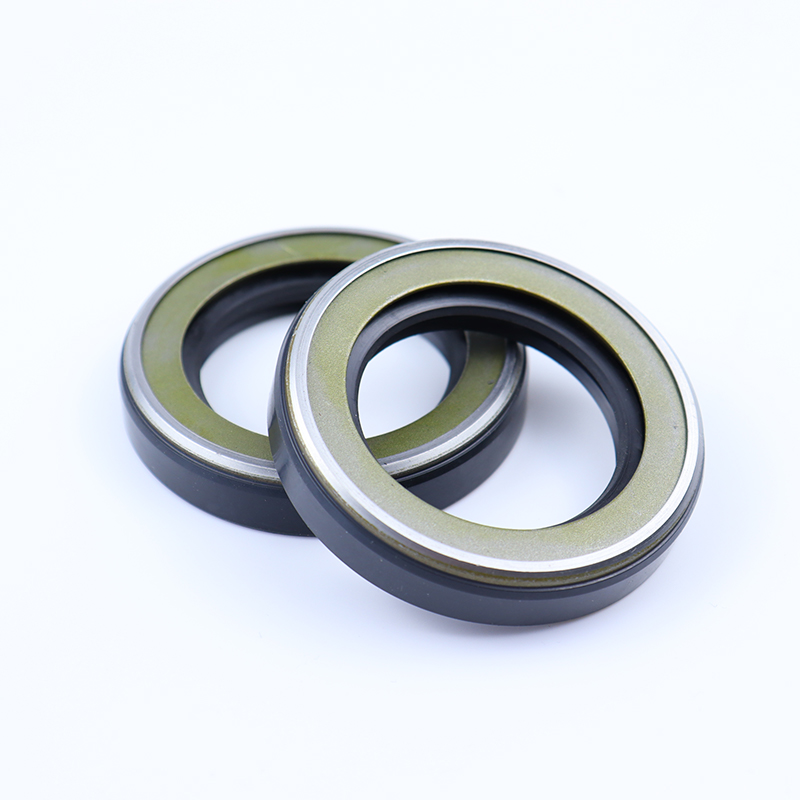

Hydraulic cylinders convert fluid power into linear motion, relying on internally sealed hydraulic fluid to generate movement. The seals, typically made of rubber or polymer materials, prevent fluid leaks and maintain pressure within the cylinder. Common seal types include O-rings, rod seals, and piston seals, each designed to withstand specific environmental conditions, pressures, and temperatures.

Signs of Worn Seals

Before diving into the replacement process, it's crucial to recognize the signs of worn seals. Common indicators include

1. Fluid Leaks External leaks around the rod or piston of the hydraulic cylinder suggest that seals are damaged or worn. 2. Decreased Performance A noticeable drop in the cylinder’s operating efficiency or speed may indicate seal failure, leading to slower movement or incomplete strokes. 3. Increased Pressure If the system requires more pressure than usual to maintain performance, it may indicate that the seals are failing to contain the hydraulic fluid effectively. 4. Unusual Noises Grinding or hissing sounds during operation can point to hydraulic fluid escaping through damaged seals.

Tools and Materials Needed

Replacing seals on a hydraulic cylinder requires specific tools and materials to ensure a successful and safe repair. Gather the following items before getting started

- Replacement seals (make sure they match the specifications for your cylinder) - Hydraulic fluid - Wrenches and sockets - Screwdrivers - Seal removal tools - Clean cloths and rags - Safety goggles and gloves

replacing seals on a hydraulic cylinder

Step-by-Step Guide to Replacing Seals

1. Preparation Before beginning any work, ensure the machinery is powered down and depressurized. Disconnect the hydraulic lines and drain any fluid from the cylinder to avoid spills and injuries.

2. Disassembly Using the appropriate tools, carefully remove the end caps and other components of the hydraulic cylinder. Take note of the order and orientation of parts for reassembly later.

3. Remove Old Seals Gently remove the worn seals from the piston and rod using seal removal tools or a flathead screwdriver. Avoid scraping the cylinder surfaces to prevent damage.

4. Clean Surfaces Thoroughly clean the cylinder bore, piston, and rod areas where the seals will be installed. Ensure that no debris or old seal material remains, as this can hinder the performance of the new seals.

5. Install New Seals Carefully place the new seals into position, ensuring they are seated correctly and seated evenly within their grooves. Use a lubricant compatible with the hydraulic fluid to facilitate installation and prevent damage to the seals.

6. Reassemble the Cylinder Follow the notes you took during disassembly to reassemble the hydraulic cylinder in the correct order. Ensure that all nuts and bolts are tightened to the manufacturer's specifications.

7. Refill and Test Once reassembled, refill the hydraulic cylinder with fluid and purge any air from the system. Test the cylinder under operational conditions while observing for any leaks or performance issues.

Final Thoughts

Replacing seals on a hydraulic cylinder is a relatively straightforward process that demands careful attention to detail and adherence to safety protocols. Regular maintenance of hydraulic systems, including timely seal replacement, can significantly reduce the risk of equipment failure, ensuring that your machinery operates smoothly and efficiently. By following this guide, you can help maintain the integrity and performance of your hydraulic cylinders, ultimately saving time and money in the long run.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories