Abe . 11, 2024 18:59 Back to list

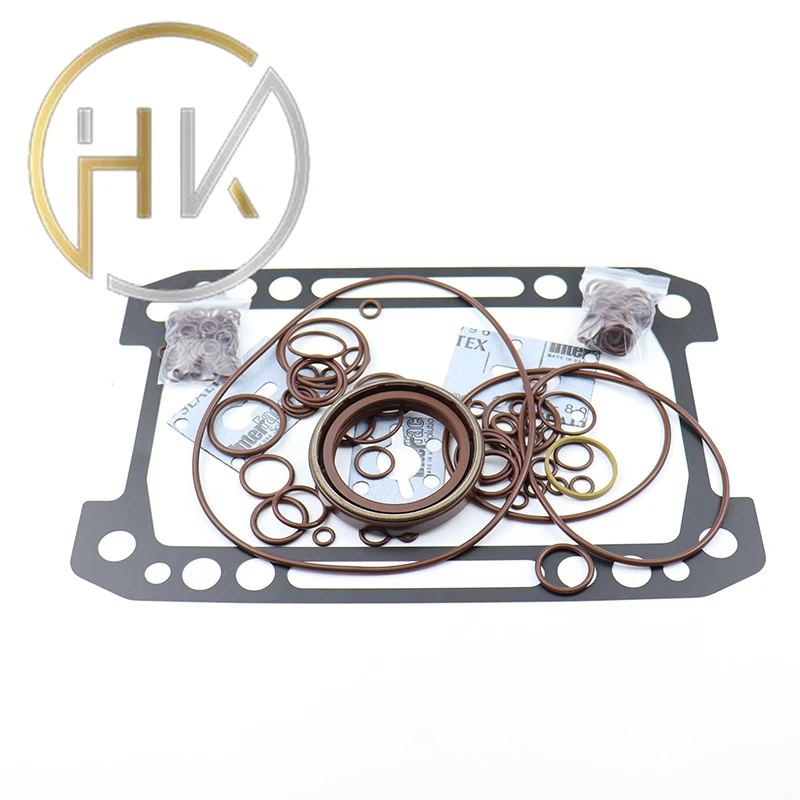

hydraulic piston seal kit

Understanding Hydraulic Piston Seal Kits

Hydraulic systems are integral to a wide range of industrial and agricultural machinery, providing precise control over movements and operations. One of the critical components in these systems is the hydraulic piston, and within it, the hydraulic piston seal kit plays a vital role in maintaining efficiency and performance. This article delves into the importance, components, selection, and maintenance of hydraulic piston seal kits.

Importance of Hydraulic Piston Seal Kits

Hydraulic piston seal kits are designed to prevent the leakage of fluid, ensuring that the hydraulic system operates effectively. They serve several essential functions

1. Leak Prevention A well-functioning seal kit prevents hydraulic fluid from escaping or entering unwanted areas. This is crucial because leaks can lead to a significant loss of pressure, reduced efficiency, and potential damage to the system.

2. Contamination Control The seals also act as barriers to contaminants such as dust, dirt, and other particulates, which can degrade the hydraulic fluid and compromise the integrity of the system.

3. Smooth Operation By maintaining proper friction levels between moving parts, seal kits facilitate smooth operation, enhancing the overall performance and longevity of equipment.

Components of a Hydraulic Piston Seal Kit

A typical hydraulic piston seal kit consists of various components, each serving a specific function

1. Piston Seals These are primary seals that fit around the piston and prevent fluid from leaking out during operation. They come in various designs, such as O-rings, U-cups, and V-rings, depending on the application.

2. Rod Seals These seals work in conjunction with piston seals, preventing fluid from leaking along the rod that drives the piston. They are crucial for maintaining pressure and preventing contamination.

3. Backup Rings Often included in seal kits, backup rings enhance the performance of the primary seals by preventing extrusion and increasing durability. They are typically made of harder materials to withstand higher pressures.

4. Wear Rings These are used to minimize friction and wear between moving parts, ensuring a longer lifespan for both the seals and the hydraulic components.

hydraulic piston seal kit

Selecting the Right Hydraulic Piston Seal Kit

Choosing the right hydraulic piston seal kit is essential for the performance of hydraulic systems. Here are some key factors to consider

1. Material Compatibility Seals can be made from various materials like nitrile, polyurethane, and fluorocarbon. Selecting a material that is compatible with the hydraulic fluid and operating environment is crucial.

2. Pressure and Temperature Ratings Ensure the seal kit can withstand the specific pressure and temperature ranges of your application to prevent premature failure.

3. Application Type Different applications may require specific seal configurations. It’s crucial to understand the operating conditions to choose the right seals.

Maintenance of Hydraulic Piston Seal Kits

Regular maintenance of hydraulic piston seal kits is essential to ensure longevity and reliability. Here are some best practices

1. Regular Inspections Periodically check the seals for signs of wear, damage, or leakage. Early detection can prevent costly repairs and downtime.

2. Fluid Quality Maintain the quality of hydraulic fluid, as contaminated or degraded fluid can drastically reduce the effectiveness of seals.

3. Environment Monitoring Ensure that the operating environment is as clean as possible to minimize contamination and wear on the seals.

Conclusion

In conclusion, hydraulic piston seal kits are a critical aspect of hydraulic systems, directly impacting their efficiency, reliability, and lifespan. By understanding their importance, components, selection criteria, and maintenance practices, operators can ensure optimal performance and minimize downtime in their hydraulic applications. Investing in quality seal kits and maintaining them properly is not just a matter of maintenance; it's a fundamental aspect of hydraulic system management that pays off in the long run.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories