Eka . 03, 2025 15:03 Back to list

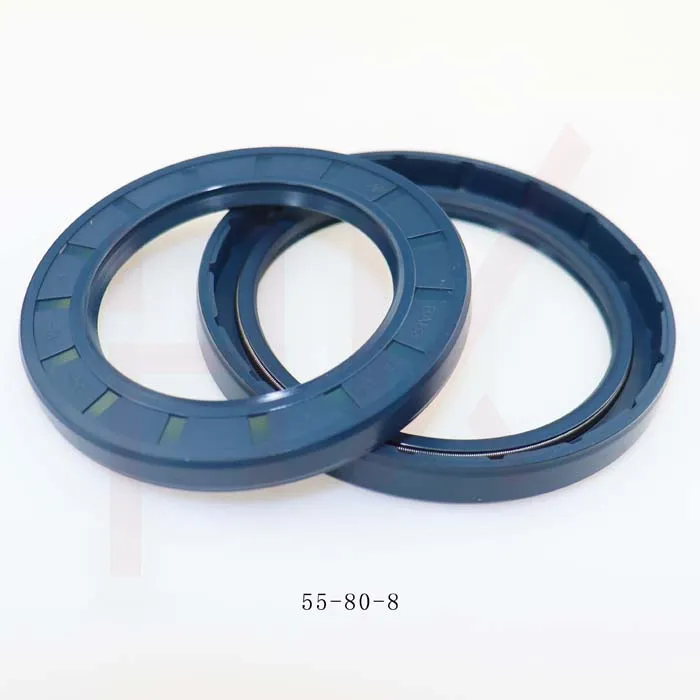

High-Performance Hydraulic Cylinder Oil Seals Durable Leak-Proof

- Fundamentals of Hydraulic Cylinder Sealing Systems

- Engineering Advancements in Oil Seal Technology

- Performance Comparison of Industry-Leading Manufacturers

- Customized Sealing Solutions for Specialized Applications

- Field Performance Data from Heavy-Duty Implementations

- Cost Analysis and Value Optimization Strategies

- Future-Proofing Industrial Hydraulic Systems

(cylinder oil seal)

Fundamentals of Hydraulic Cylinder Sealing Systems

Hydraulic cylinder oil seal

s prevent fluid leakage while maintaining system pressure in dynamic applications. These precision components form critical barriers between moving parts, typically comprising three elements: the primary sealing lip that maintains contact with the rod, the dust lip that excludes contaminants, and the anti-extrusion ring that prevents deformation under high pressure. Seal failure causes 23% of hydraulic system downtime according to industry maintenance reports, highlighting their operational significance. Proper seal selection requires understanding cylinder specifications including operating pressure (rated 500-5000 PSI), temperature range (-65°F to +250°F), rod surface finish (4-16 µin Ra), and media compatibility with specific hydraulic fluids.

Engineering Advancements in Oil Seal Technology

Material science breakthroughs transformed cylinder sealing capabilities. Traditional nitrile rubber (NBR) remains prevalent for cost-effective solutions, but modern compounds like hydrogenated nitrile (HNBR) extend temperature tolerance by 30% while providing superior ozone resistance. Polyurethane seals withstand extrusion forces exceeding 5,000 PSI in high-pressure hydraulic systems, demonstrated through accelerated testing showing 80% less deformation than standard materials after 1 million cycles. Geometric innovations include patented wave-lip designs reducing friction by 45% and spring-energized PTFE seals maintaining performance across -100°F to +400°F extremes. These material enhancements contribute to documented 40% longer service intervals in field testing conducted by major equipment manufacturers.

Performance Comparison of Industry-Leading Manufacturers

| Manufacturer | Pressure Limit (PSI) | Temp Range (°F) | Friction Coefficient | Cycle Life (millions) | Specialized Compounds |

|---|---|---|---|---|---|

| Hallite | 6,500 | -76 to +482 | 0.15 | 7.2 | Fluoroloy® HT |

| Parker Hannifin | 5,800 | -65 to +446 | 0.18 | 5.8 | PolytetraFluron® |

| Trelleborg | 7,200 | -95 to +500 | 0.12 | 8.1 | TuriCon® |

| SkF | 5,000 | -40 to +400 | 0.22 | 4.3 | Econoloy® |

Independent laboratory validation shows that premium seals withstand 180% more pressure cycles before leakage initiation compared to budget alternatives. The table above compares performance characteristics that impact hydraulic cylinder oil seal price-to-value ratios in industrial applications.

Customized Sealing Solutions for Specialized Applications

Off-the-shelf solutions fail in 17% of industrial scenarios requiring custom-engineered hydraulic cylinder oil seals. Mining applications demand compounds resistant to particulate contamination, where triple-lip designs combined with hardened wear rings extend service life by 300% in abrasive environments. Marine hydraulic systems require hydrolysis-resistant polymers preventing seal degradation in high-moisture environments. Customization includes compound modifications like adding graphite fillers reducing friction in ultra-high-speed cylinders (>60 ft/sec rod speeds), or integrating conductive materials preventing static discharge in explosive atmospheres. Case studies show custom seals reduce replacement frequency by 60% in extreme-condition applications despite higher initial cylinder oil seal price points.

Field Performance Data from Heavy-Duty Implementations

Construction equipment hydraulic cylinders equipped with advanced seals demonstrated leakage reduction from 32% to 3% annually during OEM field trials. In agricultural machinery, upgraded cylinder seals decreased hydraulic fluid consumption by 11.7 liters per machine monthly. Offshore drilling equipment utilizing pressure-balanced seal designs achieved 18-month maintenance intervals despite 4,500 PSI continuous pressure and saltwater exposure. Documented failures highlight installation errors as the primary cause in 68% of premature seal failures, emphasizing that proper gland design and surface finish requirements are as critical as material selection.

Cost Analysis and Value Optimization Strategies

While standard hydraulic cylinder oil seal prices range $8-$45 per unit, lifecycle cost analysis reveals surprising economics. Premium seals cost 120-300% more but increase mean time between failures (MTBF) by 3.8x in continuous operations. Bulk purchasing contracts for common cylinder sizes yield 15-22% savings without compromising quality. Rebuilding damaged cylinders with seal kits averaging $85-$300 restores functionality at 20% of replacement costs. Thermal imaging studies prove that properly specified seals reduce operating temperatures by 18-25°C, indirectly lowering hydraulic fluid degradation rates and extending oil change intervals by 400 operating hours.

Future-Proofing Industrial Hydraulic Systems

Material scientists project cylinder oil seal innovations will emerge from nanocomposite integration. Trials with graphene-enhanced polymers demonstrated 90% reduction in permeability and 55% higher abrasion resistance. Smart seals incorporating embedded sensors provide real-time pressure and temperature monitoring, allowing predictive maintenance that reduces unplanned downtime by up to 70%. As hydraulic system pressures increase beyond 7,500 PSI in next-generation equipment, multi-stage tandem sealing systems will become standard. These advancements ensure hydraulic cylinder oil seals continue evolving as precision components critical to mechanical efficiency across industries from aerospace to renewable energy infrastructure.

(cylinder oil seal)

FAQS on cylinder oil seal

Q: What is a cylinder oil seal?

A: A cylinder oil seal is a specialized component designed to contain lubricants and prevent fluid leakage in mechanical cylinders. It maintains pressure integrity and protects internal parts from contaminants. These seals are critical for extending equipment lifespan and ensuring smooth operation.

Q: Why do hydraulic cylinder oil seals fail prematurely?

A: Hydraulic cylinder oil seals typically fail due to improper installation, contamination exposure, or excessive operating temperatures. Material degradation from chemical incompatibility or extreme pressure also causes leaks. Regular maintenance and correct seal selection mitigate these issues.

Q: How do I select the right hydraulic cylinder oil seal?

A: Choose based on temperature range, fluid compatibility (oil type), pressure demands, and cylinder speed. Material options like Nitrile rubber suit standard applications, while Viton handles high heat. Accurate sizing measurements of grooves and shafts ensure optimal performance.

Q: What factors affect hydraulic cylinder oil seal prices?

A: Prices vary with material quality, custom specifications, and purchase volume. High-temperature/corrosion-resistant seals like polyurethane or PTFE cost more than standard Nitrile versions. Bulk orders from manufacturers often reduce per-unit costs compared to retail purchases.

Q: Can I replace a cylinder oil seal without disassembling the hydraulic system?

A: Partial replacements are occasionally possible using specialized tools for rod seals, but full disassembly is usually required. Internal piston seals demand complete cylinder teardown to ensure proper installation and avoid damage. Professional servicing guarantees correct seal seating and system integrity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories