Abu . 05, 2024 20:51 Back to list

Choosing the Right 22x35x7 Oil Seal for Optimal Performance and Durability in Your Equipment

Understanding the 22x35x7 Oil Seal A Comprehensive Guide

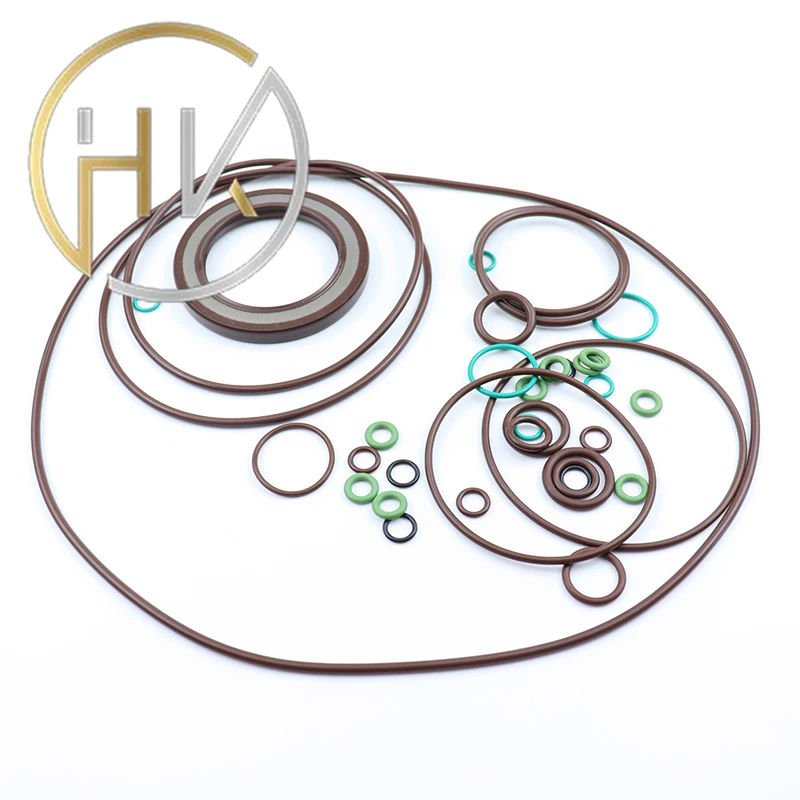

Oil seals, also known as grease seals or shaft seals, play a crucial role in various mechanical systems by preventing the leakage of lubricants and stopping the ingress of dirt, dust, and moisture. Among the many varieties available, the 22x35x7 oil seal stands out due to its specific dimensions and versatile applications in different machinery.

Dimensions and Specifications

The designation 22x35x7 represents the oil seal's diameter and thickness - 22 mm This is the inside diameter, which needs to fit snugly around the shaft to ensure a proper seal. - 35 mm This is the outside diameter, indicating the size of the opening that the seal fits into. - 7 mm This is the thickness of the seal, which can affect its resistance to wear and its ability to maintain a seal under various conditions.

The design of an oil seal can vary, but generally, they consist of a rubber outer casing, a metal reinforcement ring, and a sealing lip. The sealing lip, which is in contact with the shaft, is crucial for ensuring a tight seal. Depending on the application, these seals can be made from different materials, including nitrile rubber, silicone, or fluorocarbon, each offering unique resistance to temperature, chemicals, and wear.

Applications

The 22x35x7 oil seal is commonly found in various industries and applications

. Some of its primary uses include1. Automotive These seals are often used in car engines, gearboxes, and differential assemblies. They help keep the lubricants contained while preventing dirt and debris from entering sensitive areas.

22x35x7 oil seal

2. Industrial Machinery In manufacturing and processing equipment, these oil seals protect bearings and other rotating components from contamination, ensuring smooth operations and longevity.

3. Agricultural Equipment Tractors and other farming machinery use these seals to help maintain hydraulic systems and gearbox components.

4. Home Appliances Washing machines and dishwashers may also utilize these seals to keep water and soap where they belong, preventing leaks and damage.

Importance of Quality

When selecting an oil seal, quality is paramount. A poor-quality seal can lead to leaks, lubrication loss, and ultimately, serious damage to machinery. Factors such as material durability, compatibility with the lubricant used, and environmental resistance should be considered. Furthermore, proper installation is critical; a misaligned seal can undermine its effectiveness and lead to premature failure.

Conclusion

In conclusion, the 22x35x7 oil seal is an essential component found in numerous mechanical systems across various industries. Understanding its dimensions, applications, and the importance of quality can help in making informed decisions when choosing the right seal for specific needs. Whether in automotive, industrial, or agricultural applications, investing in high-quality oil seals is crucial for ensuring operational efficiency, extending the lifespan of machinery, and ultimately saving on maintenance costs. Therefore, when faced with the need for an oil seal, considering the specifications and quality of the product will go a long way in maintaining optimal performance.

-

Durable 22x35x6 TCV Oil Seals: FKM & NBR for Hydraulic Pumps

NewsSep.01,2025

-

Cassette Seal 15018014.5/16 Hub Oil Seal | OEM Quality 000051785

NewsAug.31,2025

-

DKBI Hydraulic Wiper Seal 20x32x6/9 | Dustproof & Standard Oil Seal

NewsAug.30,2025

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

NewsAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

Products categories