okt. . 31, 2024 09:09 Back to list

hydraulic seal repair kit

Understanding Hydraulic Seal Repair Kits

Hydraulic systems are integral to various machinery and equipment, facilitating the transfer of power through fluid pressurization. However, like all mechanical systems, they are susceptible to wear and tear, especially in the seals that maintain system integrity. This is where hydraulic seal repair kits come into play, offering a practical solution for upkeep and maintenance.

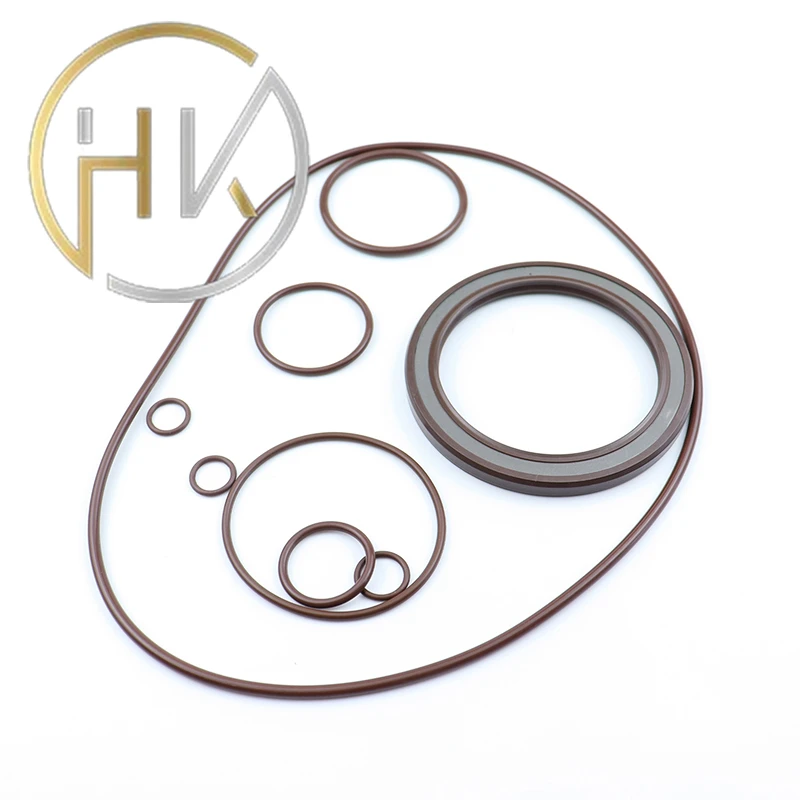

A hydraulic seal repair kit typically contains a variety of seals, O-rings, and other components designed to replace worn or damaged parts in hydraulic systems. These kits are essential for preventing leaks, which can lead to loss of fluid, decreased performance, and potential damage to the machinery. Regular maintenance using these kits ensures that hydraulic systems operate efficiently and reduces downtime due to repairs.

One of the key benefits of hydraulic seal repair kits is their affordability and convenience. Purchasing a complete kit is often more economical than individually sourcing components. These kits are designed to cater to a wide array of hydraulic applications, making them versatile for various industries, including construction, manufacturing, and automotive.

hydraulic seal repair kit

When selecting a hydraulic seal repair kit, it’s important to consider the specific requirements of your hydraulic system. Factors such as the type of fluid used, operating temperature, and pressure ratings play a crucial role in determining the appropriate materials for seals and O-rings. Many kits come with detailed specifications, making it easier for users to find the right fit.

Using a hydraulic seal repair kit usually involves several steps. First, the damaged seals must be identified and located. The hydraulic system should be depressurized and drained to prevent any accidental leaks or injuries. Next, the old seals are carefully removed, and the replacement seals from the kit are installed. It’s crucial to ensure a proper fit to maintain system integrity. Finally, the system is recharged and tested to confirm that the repair was successful and no leaks are present.

In conclusion, hydraulic seal repair kits are essential for maintaining the efficiency and longevity of hydraulic systems. They provide a cost-effective solution for repairing seals and preventing fluid leaks. By investing in a high-quality kit and adhering to proper installation practices, operators can ensure the reliability of their machinery. Regular maintenance using these kits not only safeguards investments but also enhances overall productivity in various applications. Thus, incorporating hydraulic seal repair kits into routine maintenance schedules is a wise decision for any industry that relies on hydraulic systems.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories