dets. . 05, 2024 14:19 Back to list

hydraulic lift cylinder seal kits

Understanding Hydraulic Lift Cylinder Seal Kits

Hydraulic systems are central to a multitude of industries ranging from construction and automotive to manufacturing and beyond. One critical component of hydraulic systems is the hydraulic lift cylinder, which relies heavily on effective seals to maintain operational efficiency and prevent fluid leaks. Hydraulic lift cylinder seal kits play a pivotal role in ensuring the longevity and reliability of these hydraulic systems.

What Are Hydraulic Lift Cylinder Seal Kits?

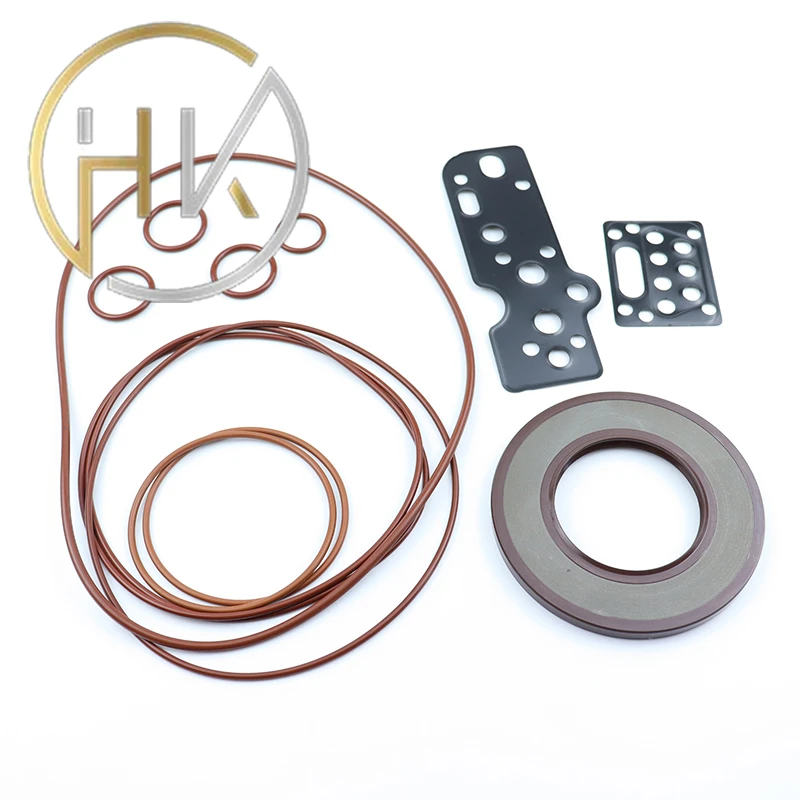

Hydraulic lift cylinder seal kits are collections of various seals and gaskets specifically designed for hydraulic cylinders. These kits typically include O-rings, piston seals, rod seals, backup rings, and dust seals, among other components. The primary function of these seals is to create a barrier that keeps hydraulic fluid contained within the cylinder, enabling smooth and efficient operation.

Importance of Seal Kits

Hydraulic cylinders depend on high-pressure hydraulic fluid to generate force. This process involves pushing a piston within a cylinder, which translates to lifting heavy loads or driving machinery. However, for this system to function effectively, seals must prevent any leakage of fluid, as even minor leaks can lead to system failure. This is where seal kits become indispensable.

When seals wear out or become damaged, they can lead to decreased pressure, reduced efficiency, and, eventually, complete hydraulic failure. Therefore, the integrity of these seals is crucial for the long-term performance of hydraulic systems. Regular maintenance that includes checking and replacing worn seals helps avoid costly downtime and repairs.

Types of Seals in Hydraulic Lift Cylinder Seal Kits

1. O-Rings O-rings are circular seals that provide a tight seal when compressed between two surfaces. They are commonly used in static and dynamic applications within hydraulic cylinders.

2. Piston Seals These seals fit around the piston and are designed to keep fluid from leaking past the piston during operation. They often accompany backup rings to enhance reliability.

hydraulic lift cylinder seal kits

3. Rod Seals Rod seals are used to prevent leakage around the rod that extends out of the cylinder. They are critical for maintaining the pressure inside the cylinder when it is in use.

4. Dust Seals Dust seals are employed to protect the inner seals from dirt and debris, which can lead to premature wear and failure. They help ensure that the hydraulic system operates smoothly in various environments.

5. Backup Rings These non-elastic rings support the primary seals and prevent extrusion due to high pressure, thereby extending the lifespan of the sealing elements.

Selecting the Right Seal Kit

Choosing the appropriate hydraulic lift cylinder seal kit requires an understanding of the specific application, including operating conditions, temperature ranges, and the type of hydraulic fluid used. Manufacturers provide specifications that detail compatible materials and dimensions, ensuring that users select kits tailored to their equipment.

Maintenance Tips

Regular maintenance of hydraulic systems, including timely inspection and replacement of seal kits, is vital. Signs of potential seal failure include visible leaks, decreased lifting capacity, or erratic operations. It is advisable to consult with professionals or refer to manufacturer guidelines when undertaking maintenance to ensure optimal performance and safety.

Conclusion

Hydraulic lift cylinder seal kits are essential components that ensure the effective functioning of hydraulic systems. By preventing leaks and maintaining pressure, these seals contribute to the reliability, efficiency, and longevity of hydraulic equipment. Understanding the types of seals and their applications, along with proper maintenance practices, can significantly enhance the operational lifespan of hydraulic lift cylinders. Investing in high-quality seal kits is not just a choice; it’s a necessity for anyone relying on hydraulic systems for their daily operations.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories