nov. . 03, 2024 00:47 Back to list

hydraulic lift cylinder seal kits

Hydraulic Lift Cylinder Seal Kits An Essential Component for Performance and Longevity

Hydraulic lift cylinders are integral to many industrial and construction applications, providing the necessary force to lift and lower heavy loads. However, to ensure optimal performance and longevity of these systems, the integrity of their seals is crucial. This is where hydraulic lift cylinder seal kits come into play, serving as fundamental components that prevent leaks and maintain the effectiveness of hydraulic systems.

Hydraulic seals are designed to keep hydraulic fluid contained within the system, preventing contamination and avoiding any loss of pressure. Over time, seals can wear out due to friction, exposure to harsh conditions, or chemical degradation. This degradation can lead to reduced efficiency, increased maintenance costs, and potentially catastrophic system failures. Therefore, using high-quality seal kits is essential for any operation relying on hydraulic lifts.

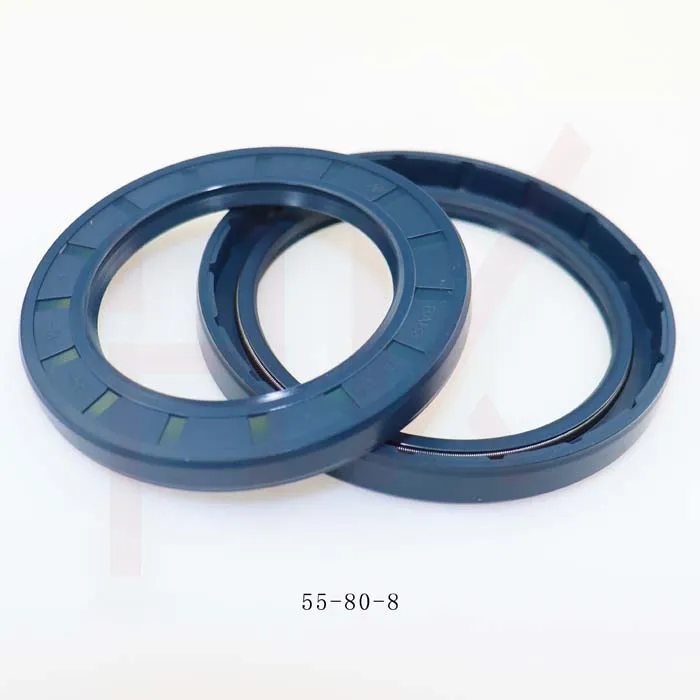

A hydraulic lift cylinder seal kit typically includes various types of seals, such as O-rings, rod seals, and piston seals, each designed for specific parts of the hydraulic cylinder. These components are made from materials like polyurethane, nitrile, and fluorocarbon, chosen for their durability and resistance to wear, tear, and temperature fluctuations. When selecting a seal kit, it is vital to consider the working conditions, including pressure, temperature, and the type of hydraulic fluid used, to ensure compatibility and performance.

hydraulic lift cylinder seal kits

Installation of a seal kit is a straightforward process, but it requires attention to detail to avoid any potential pitfalls. Proper disassembly of the hydraulic cylinder is essential, and cleaning the cylinder thoroughly before installation helps avoid contamination. Operators should inspect the cylinder for scratches or damage that could compromise the integrity of the new seals. Following the manufacturer's specifications during installation ensures that the seals are placed correctly, maintaining the performance and safety of the system.

Regular maintenance and timely replacement of hydraulic lift cylinder seal kits are crucial for preventing costly downtime. Implementing a proactive maintenance schedule allows operators to monitor the condition of seals and replace them as needed, thereby extending the life of the hydraulic lift system and enhancing overall productivity.

In conclusion, hydraulic lift cylinder seal kits are vital components in maintaining the efficiency and safety of hydraulic systems. By understanding their importance and ensuring proper installation and maintenance, businesses can achieve reliable performance and minimize repair costs. Investing in quality seal kits not only protects the hydraulic systems but also enhances operational productivity, making them indispensable in various industries.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories