nov. . 08, 2024 04:07 Back to list

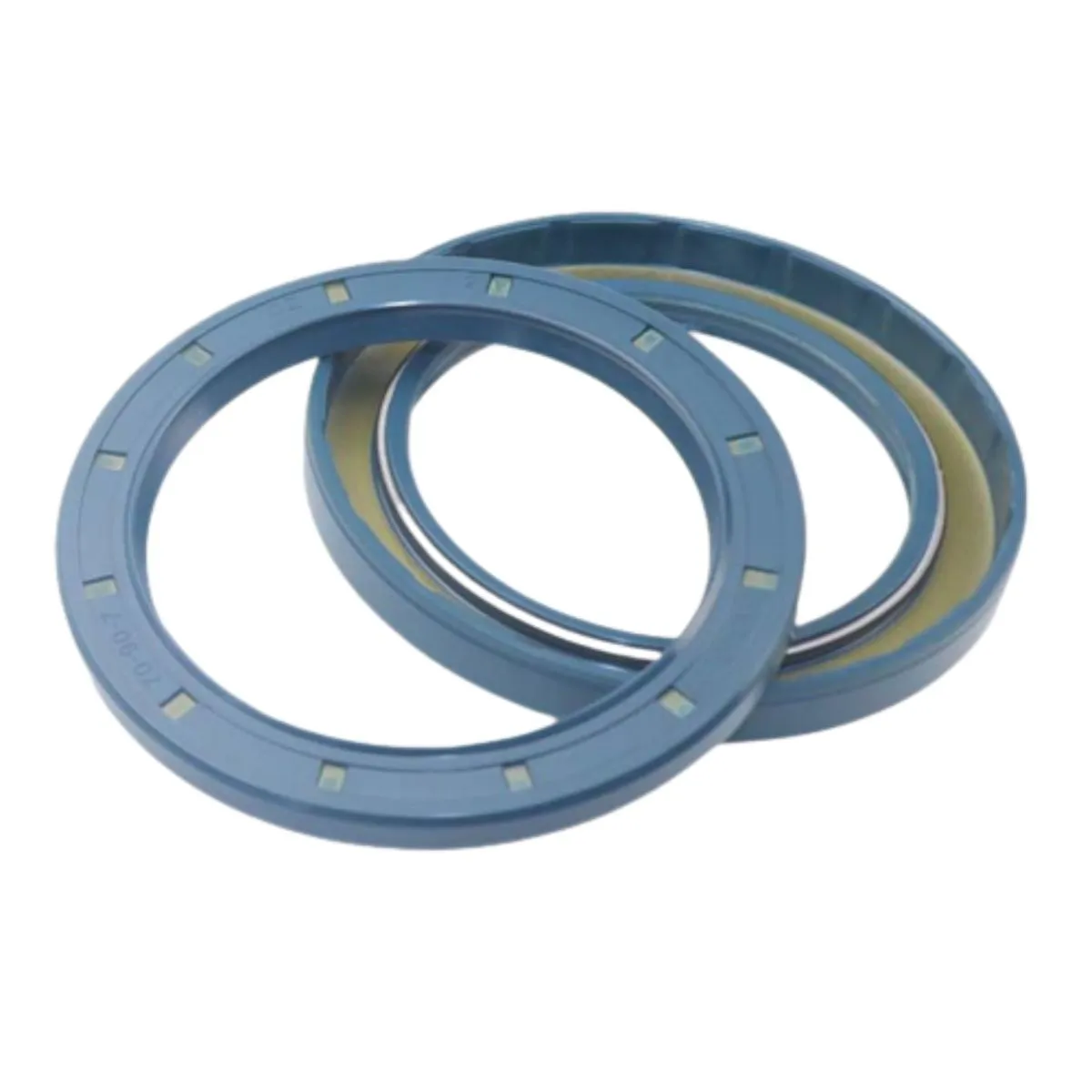

Excavator Cylinder Sealing Kits for Enhanced Performance and Durability in Heavy Machinery

Understanding Excavator Cylinder Seal Kits Importance and Maintenance

Excavators are indispensable machines in construction, mining, and various industrial applications, primarily due to their ability to handle heavy loads and perform demanding tasks. At the heart of an excavator's performance lies its hydraulic system, which relies on an intricate assembly of components, including cylinders and seals. Among these, the excavator cylinder seal kits play a vital role in ensuring optimal functionality and longevity of the machinery.

What Are Excavator Cylinder Seal Kits?

Excavator cylinder seal kits are specially designed sets of seals that are used in hydraulic cylinders. These kits contain various types of seals, including o-rings, back-up rings, dust seals, and piston seals, which function collectively to prevent leaks and maintain pressure within the hydraulic system. The seals are typically made from durable materials like polyurethane, rubber, or PTFE, which can withstand extreme temperatures, pressures, and exposure to hydraulic fluids.

Importance of Seal Kits

1. Preventing Hydraulic Fluid Leaks Hydraulic systems operate under significant pressure. If the seals wear out or are damaged, hydraulic fluid can leak, leading to reduced efficiency and potential catastrophic failure of the cylinder. Seal kits prevent these leaks, ensuring that the system operates smoothly.

2. Enhancing Performance Properly functioning seals contribute to the overall performance of the excavator. When hydraulic fluid is contained effectively, the equipment can generate the necessary force required for lifting, digging, or pushing, thereby enhancing productivity.

3. Extending Equipment Life Regular maintenance and timely replacement of seal kits not only keep the hydraulic system functioning efficiently but also extend the overall lifespan of the excavator. Neglecting worn seals can lead to extensive damage that may require costly repairs or even complete replacement of the hydraulic cylinder.

4. Safety A well-sealed hydraulic system is crucial for the safety of operators and those nearby. Hydraulic failures can result in sudden loss of control, leading to accidents and injuries. By ensuring that seal kits are in good condition, operators can minimize potential risks.

excavator cylinder seal kits

Maintenance of Excavator Cylinder Seal Kits

To ensure the longevity and effectiveness of seal kits, regular maintenance is essential. Here are key points to consider

1. Routine Inspections Frequent checks of the hydraulic system can help identify early signs of wear or damage. Look for any signs of fluid leaks around the hydraulic cylinders, and inspect the seals for any signs of deterioration.

2. Replace Worn Out Seals If any seal shows signs of wear, such as cracks, discoloration, or brittleness, it’s critical to replace it immediately. Ignoring these signs can lead to more significant problems down the line.

3. Use Quality Seal Kits When replacing seal kits, always opt for quality products from reputable manufacturers. Low-quality seals may not perform under high pressure or extreme conditions, leading to premature failure.

4. Proper Installation Ensuring the correct installation of seal kits is vital. Improper alignment or installation can lead to premature wear or failure. It's advisable to refer to the manufacturer's guidelines or hire a professional for installation.

5. Hydraulic Fluid Maintenance The type and condition of hydraulic fluid used can also impact the effectiveness and lifespan of seals. Regularly check and replace hydraulic fluid as needed, ensuring it is compatible with the seal materials.

Conclusion

In summary, excavator cylinder seal kits are critical components that significantly influence the performance and safety of excavators. Regular maintenance, timely replacement, and adherence to quality standards are paramount to ensure these seals perform their role effectively. By prioritizing the upkeep of your excavator’s hydraulic system, you can enhance productivity, extend equipment life, and promote a safe working environment. Proper attention to seal kits not only saves costs in the long run but also ensures that your excavator remains a reliable partner in your projects.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories