Feb . 20, 2025 10:15 Back to list

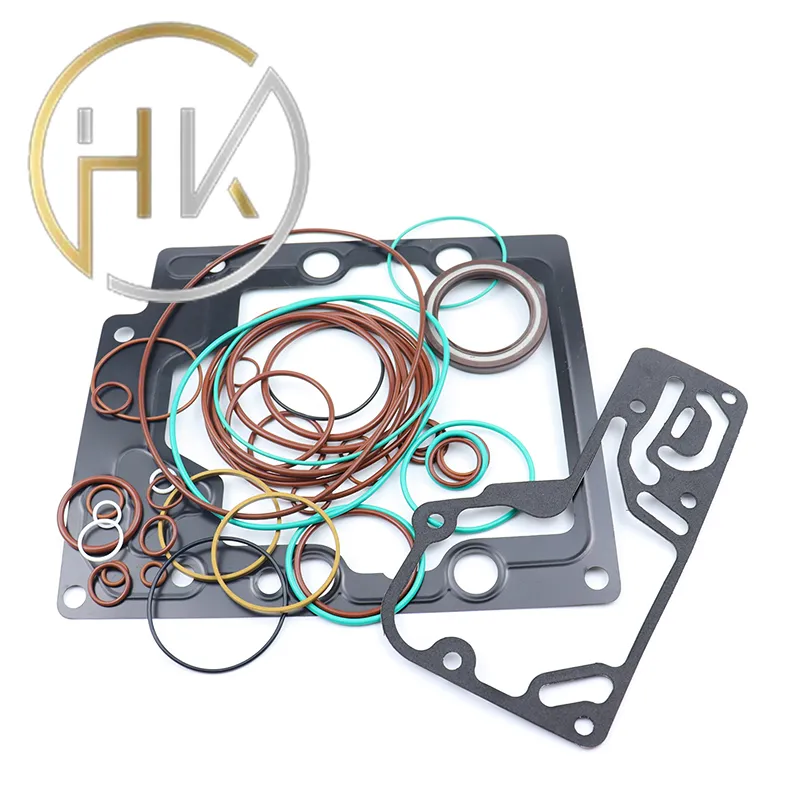

185*205*11 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

Purchasing volume is another determinant in pricing strategies. Bulk orders typically benefit from scaled discounts, driving overall unit prices down. Industries planning long-term maintenance schedules can capitalize on bulk purchasing agreements, locking in current prices and safeguarding against future market volatility. Establishing reliable supplier relationships can lead to advantageous terms and conditions, fostering an environment of trust and mutual benefit. Despite initial purchase costs, it's paramount to consider the total cost of ownership. Investing in high-quality, durable oil seals can reduce maintenance frequency, machinery downtime, and potential lost production time, offering a more economical solution over the lifecycle. Industry veterans assert that by evaluating seals on performance rather than mere price, organizations can achieve cost efficiencies that align with operational goals. For businesses keen on maintaining machinery efficacy and prolonging lifespan, navigating the oil seal market requires a blend of technical knowledge and strategic planning. Consulting with experienced suppliers and leveraging technical expertise can aid in selecting the right seal at the right price. Thoroughly understanding the interplay between materials, manufacturing processes, and market dynamics can empower decision-makers to make informed purchasing choices. In conclusion, while the oil seal price might seem like a straightforward metric, its nuances are complex and layered with diverse considerations. Continuous education and a strategic approach to procurement ensure that organizations procure seals that serve their functional needs while respecting budgetary constraints. As the industrial sector evolves, staying agile and knowledgeable in oil seal selection and pricing dynamics remains a cornerstone of operational success.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories