dec . 12, 2024 04:50 Back to list

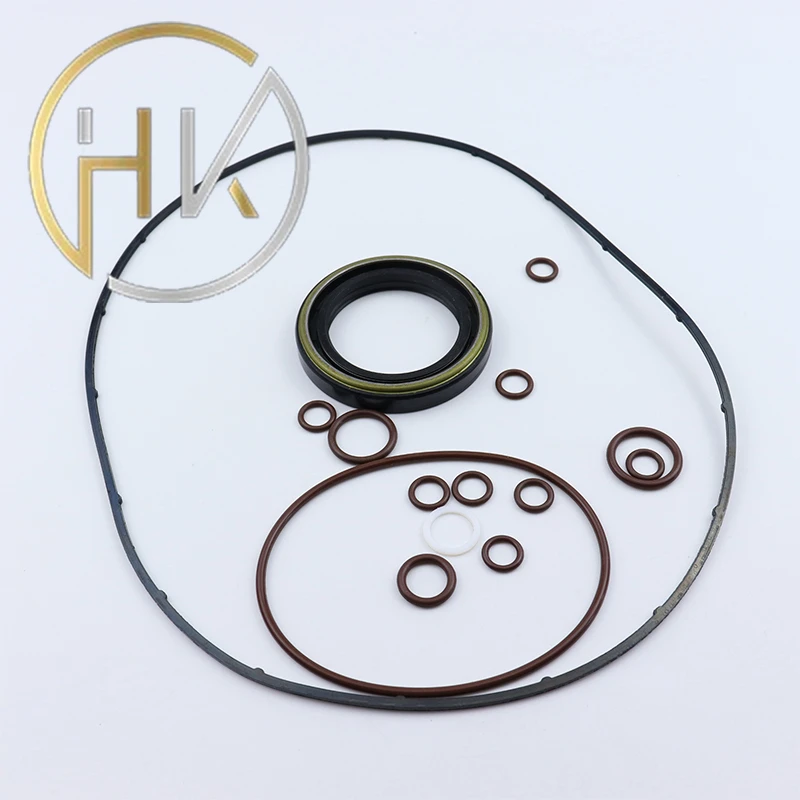

35 47 7 oil seal

Understanding the Importance of a 35% 2047 7 Oil Seal

Oil seals are critical components in various mechanical systems. They play crucial roles in preventing leakage, minimizing contamination, and ensuring the efficient operation of machinery. The 35% 2047 7 oil seal is a specific type of oil seal that has gained attention due to its unique specifications and applications. In this article, we will explore its significance, features, and general applications.

What is an Oil Seal?

An oil seal, also known as a shaft seal or rotary seal, is designed to retain lubricants within a mechanical assembly while keeping out dust, dirt, and other contaminants. Typically made from durable materials such as rubber, metal, or a composite, oil seals are found in various machines – from automotive engines to industrial equipment.

Deciphering the 35% 2047 7 Designation

The designation 35% 2047 7 can be broken down into recognizable segments. Generally, the first number (35) refers to the inner diameter of the oil seal in millimeters. The subsequent numbers may indicate specific features, such as the cross-section, material composition, or design specifications that define its operational characteristics.

For instance, 2047 might refer to a specific design series or material blend, denoting how the seal is formulated to withstand temperature variations, pressures, and the specific types of lubricants it will come in contact with. Lastly, 7 might represent a particular performance specification – such as resistance to certain chemicals, environmental conditions, or a related standard.

Features of the 35% 2047 7 Oil Seal

1. Material Composition The effectiveness of any oil seal is greatly influenced by its material. The 35% 2047 7 oil seal is often made from high-performance elastomers, which offer excellent flexibility and resilience. These materials are resistant to wear, extend service life, and meet varying temperature and pressure demands.

2. Design and Profile Like many oil seals, the 35% 2047 7 may feature a lip design that ensures a tight seal around rotating shafts. This design helps maintain a fine balance between preventing leaks while reducing friction - a factor that can significantly affect the efficiency and longevity of machinery.

35 47 7 oil seal

3. Versatility Many users opt for the 35% 2047 7 oil seal due to its compatibility with a wide range of applications. Whether in automotive, agricultural, marine, or industrial sectors, this oil seal is beneficial in environments that require consistent performance to prevent leakage and contamination.

4. Temperature and Chemical Resistance Oil seals often encounter extreme working conditions, from fluctuating temperatures to exposure to various chemicals. The 35% 2047 7 oil seal is engineered to withstand such challenges, aiding in the performance of the overall machinery.

Applications of the 35% 2047 7 Oil Seal

The 35% 2047 7 oil seal finds application across diverse sectors. Here are a few examples

1. Automotive Industry In vehicles, oil seals are essential for engines, transmissions, and differentials. The 35% 2047 7 oil seal can provide reliable sealing solutions, preventing oil leaks that can lead to significant engine damage.

2. Industrial Machinery Heavy equipment and manufacturing systems rely on various moving parts that require effective sealing to avoid costly downtimes. The 35% 2047 7 oil seal serves as an integral component in maintaining operational efficiency.

3. Agricultural Equipment With equipment exposed to harsh conditions, a robust oil seal like the 35% 2047 7 can protect against dirt and water ingress, ensuring the longevity and reliability of machinery used in farming.

4. Marine Applications Boat engines and related machinery require high-performance seals to avoid water intrusion and ensure optimal function under demanding conditions.

Conclusion

The 35% 2047 7 oil seal is a prime example of the vital role that small components play in larger mechanical systems. With its specific features and durability, it enhances performance while safeguarding machinery against leaks and contamination. Whether in automotive, industrial, agricultural, or marine applications, understanding the importance of such oil seals can lead to improved reliability and efficiency. The meticulous selection and application of the right oil seal can greatly contribute to the overall performance and lifespan of mechanical systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories