Ιαν . 17, 2025 01:06 Back to list

seal kit hydraulic

Moreover, maintaining these hydraulic seals is equally crucial. Regular inspection for signs of wear or damage is necessary, as compromised seals can lead to significant performance drops or full system failure. Replacing seals at recommended intervals not only extends the life of your hydraulic system but also optimizes operational efficiency. Investing in high-quality hydraulic seal kits is a forward-thinking approach that pays dividends in operational reliability and cost efficiency. With advances in technology, modern seals are designed to withstand more rigorous conditions than ever before, providing an excellent return on investment for businesses relying on hydraulic machinery. In conclusion, hydraulic seal kits are the unsung heroes in the realm of machinery and industrial equipment. Their importance cannot be overstated as they ensure smooth, efficient, and reliable operations across varied sectors. By understanding their role, selecting the right seal kit, and adhering to maintenance best practices, companies can safeguard their investments and enhance productivity. Whether you are an industry novice or a seasoned professional, recognizing the pivotal role of hydraulic seal kits empowers you to make better decisions that stand the test of time.

-

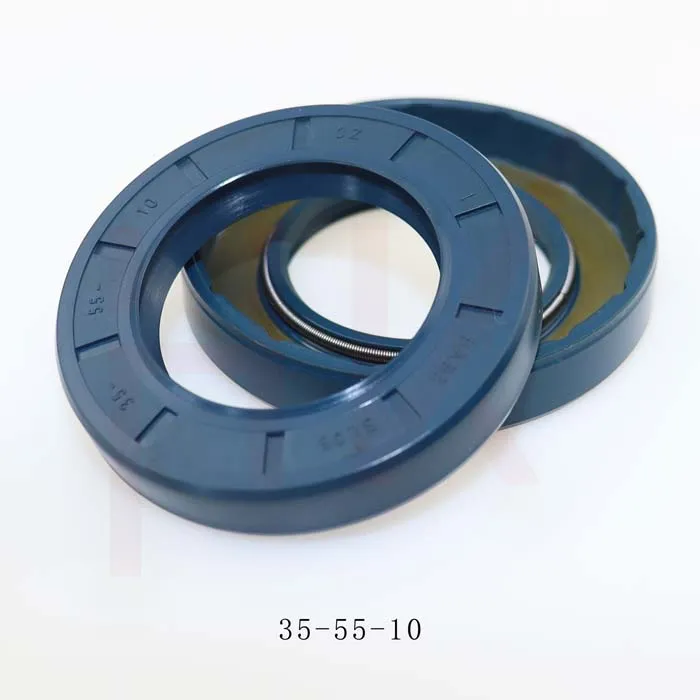

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories