Νοέ . 16, 2024 07:17 Back to list

20 32 6 oil seal

Understanding the Importance of the 20% 2032 6 Oil Seal

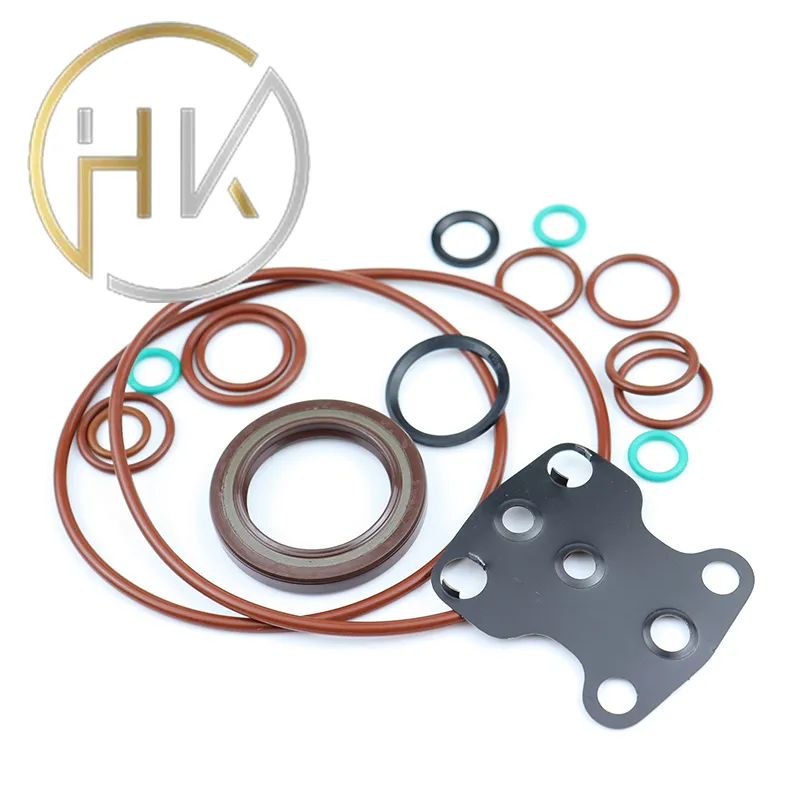

Oil seals play a crucial role in the functionality and longevity of machinery and automotive components. Among various types, the 20% 2032 6 oil seal stands out for its specific design and application. This article delves into the characteristics and significance of this particular oil seal, highlighting its applications and benefits in industrial and automotive settings.

What is an Oil Seal?

An oil seal, also known as a rotary shaft seal, is a device used to retain lubricant in a mechanical assembly while preventing the leakage of oil, dirt, and contaminants. Its primary function is to protect the internal components from external elements that can contribute to wear and tear. Oil seals are essential in ensuring the efficient operation of machinery, ensuring that critical functions are performed without interruption.

Characteristics of the 20% 2032 6 Oil Seal

The designation 20% 2032 6 oil seal provides insight into its dimensions and material properties. The “20%” indicates a specific formulation of materials that enhances the seal's ability to withstand various operating conditions. This composition typically includes rubber compounds that provide flexibility and resilience, ensuring a tight fit and effective sealing capabilities.

The numeric designation, 2032, is critical for understanding the seal's size. These numbers refer to the dimensions, such as the inner diameter, outer diameter, and thickness, which are essential for compatible applications. The correct fit prevents any chance of leakage, thereby maintaining the integrity of the machinery.

Finally, the 6 may refer to the design standard or the specific variant of the seal, which can indicate its intended application in various environments, from automotive engines to industrial machinery.

Applications of the 20% 2032 6 Oil Seal

20 32 6 oil seal

The 20% 2032 6 oil seal finds applications in a variety of sectors, including automotive, aerospace, marine, and manufacturing. In automotive applications, these seals are commonly used in engine components, gearboxes, and differential housings, ensuring that lubricants stay contained and operational efficiency is maintained.

In the aerospace industry, where the reliability of components is critical, this oil seal helps prevent leaks in hydraulic systems and engines, contributing to the overall safety and performance of aircraft. Similarly, in marine applications, where equipment is often exposed to harsh environmental conditions, high-quality oil seals like the 20% 2032 6 are essential in maintaining the longevity and efficiency of machinery.

Benefits of Using the 20% 2032 6 Oil Seal

Employing the 20% 2032 6 oil seal provides numerous advantages. First and foremost, its effective sealing performance helps reduce maintenance costs associated with leakage and contamination. By keeping lubricants in place and preventing contaminants from entering, the seal enhances the lifespan of machinery components, reducing the need for frequent replacements.

Additionally, the robust material composition offers excellent resistance to wear, temperature, and chemicals, ensuring that it performs well even under extreme conditions. This reliability translates to increased operational uptime, which is crucial in industrial settings where every minute counts.

Moreover, installing the correct oil seal can improve energy efficiency. Leakages often lead to unnecessary energy consumption, and a well-fitted oil seal ensures that machinery operates smoothly, thereby saving energy and reducing operational costs.

Conclusion

In conclusion, the 20% 2032 6 oil seal is an integral component in various mechanical systems, playing a vital role in ensuring proper lubrication and protection against contaminants. Its design and material composition make it suitable for numerous applications across different industries. By investing in high-quality oil seals like the 20% 2032 6, businesses can achieve enhanced performance, reduced maintenance costs, and prolonged equipment lifespan, making it a wise choice for any mechanical application.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories